Glass substrate cutting equipment and cutting method

A technology for glass substrates and cutting equipment, applied in glass manufacturing equipment, glass cutting devices, optics, etc., can solve the problems of inability to meet the refined production of liquid crystal panels, affecting the cutting quality of glass substrates, and easy wear and dullness of the cutter head. The effect of speeding up cutting efficiency, speeding up cutting quality and avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

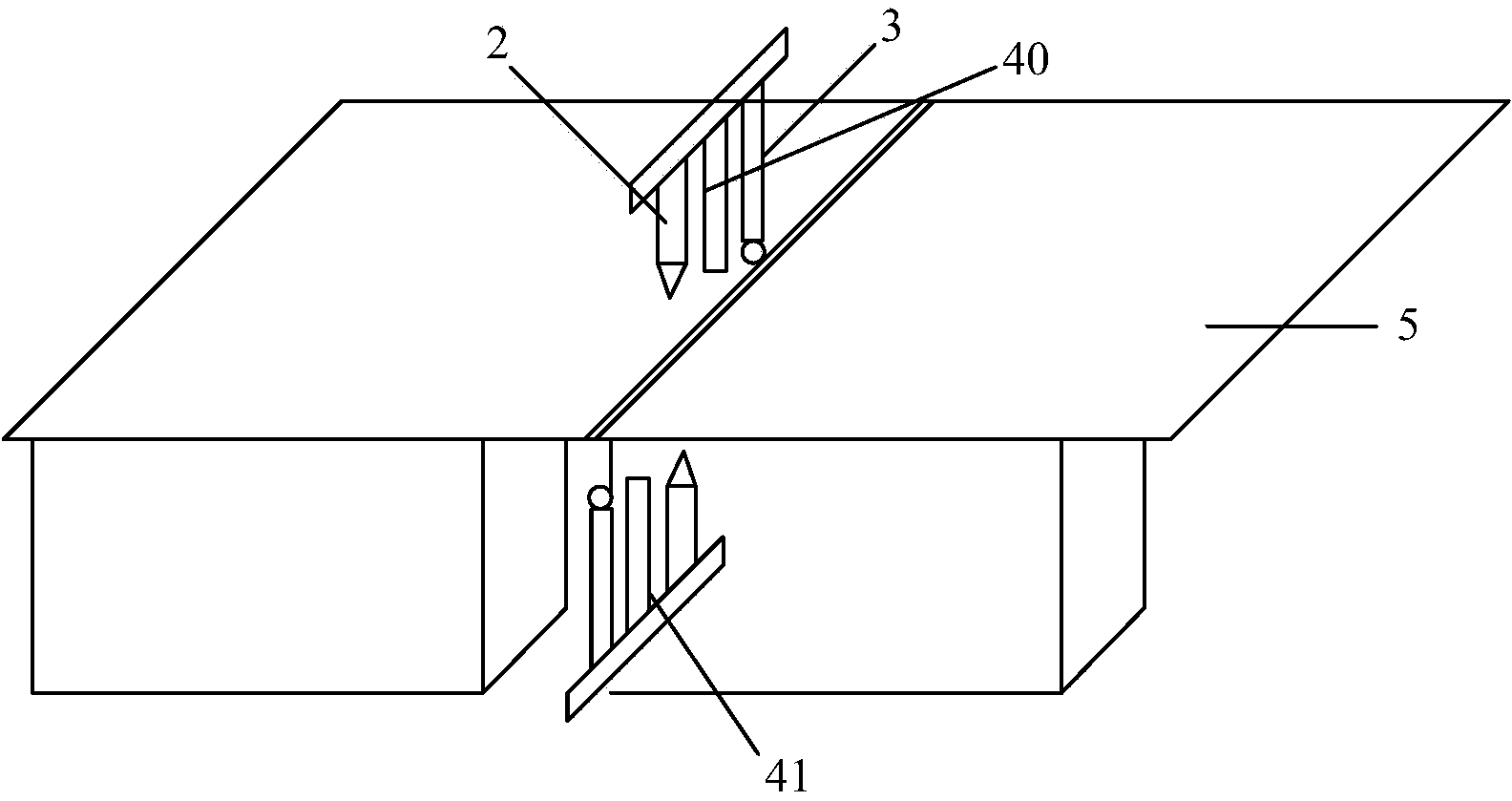

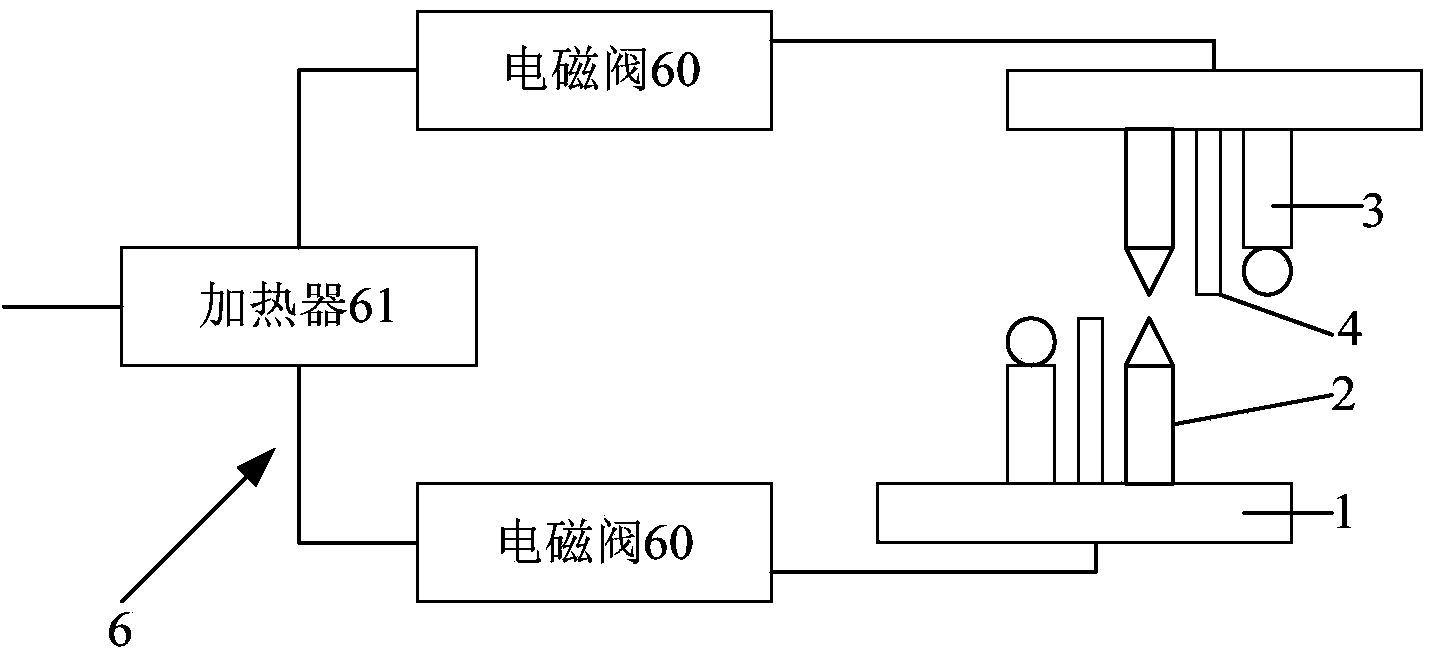

[0020] In order to speed up the cutting efficiency of the glass substrate and improve the cutting quality, the present invention provides a glass substrate cutting equipment, including a worktable 1, a cutting knife 2, a roller 3 and a high-pressure needle nozzle 4, a cutting knife 2, a roller 3 and a high-pressure needle nozzle 4 are arranged in pairs and are symmetrically installed on the upper and lower ends of the glass substrate 5. The glass substrate 5 is transferred on the workbench 1, and the cutting knife 2 includes an upper cutting knife 20 and a lower cutting knife 21, which are respectively arranged on the upper and lower ends of the glass substrate 5 and the knife edges are opposite to each other, so that the upper and lower sides of the glass substrate 5 The glass substrate 5 is cut into two halves. The roller 3 is arranged on the upper end of the glass substrate 5, and the glass substrate 5 can be pressed along the cutting cracks on the glass substrate 5 to break ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com