A method for eliminating the tiger skin defect of polypropylene composition and the polypropylene composition prepared thereof

A technology of polypropylene composition and tiger skin pattern, which is applied in the field of polymer material polypropylene, can solve the problems such as no industrialized production plan, achieve a large degree of indeterminate shape, eliminate tiger skin pattern, and increase the effect of mutual fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

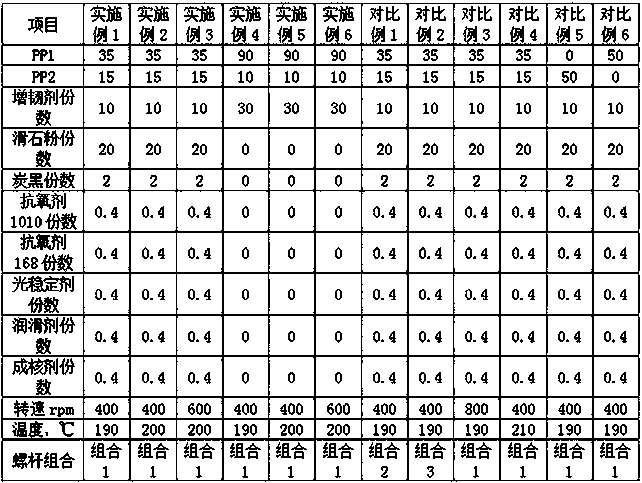

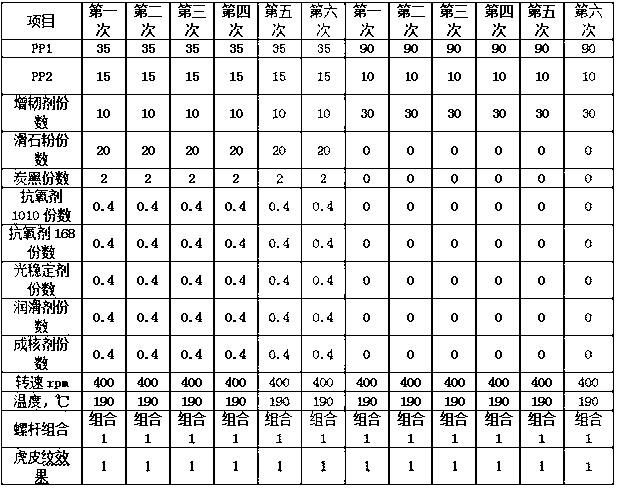

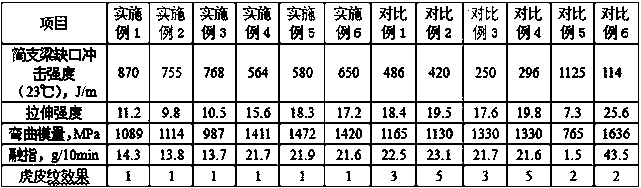

Examples

Embodiment 1

[0038] Mix the raw materials of the polypropylene composition according to the ratio in Table 1, and then add them to the twin-screw extruder, and select the screw combination 1 for melt mixing, that is, the screw combination sequence of the melting and plasticizing section of the extruder is 45 / 5 / 42 , 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42 L, in the mixing and dispersing section The screw combination sequence is 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42. The temperature of each section of the extruder is 190° C., and the screw speed is 400 rpm, and extruded and granulated to obtain a polypropylene composition.

Embodiment 2

[0040] Mix the raw materials of the polypropylene composition according to the ratio in Table 1, and then add them to the twin-screw extruder, and select the screw combination 1 for melt mixing, that is, the screw combination sequence of the melting and plasticizing section of the extruder is 45 / 5 / 42 , 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42 L, in the mixing and dispersing section The screw combination sequence is 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42. The temperature of each section of the extruder is 200° C., the screw speed is 400 rpm, extruded and granulated to obtain a polypropylene composition.

Embodiment 3

[0042] Mix the raw materials of the polypropylene composition according to the ratio in Table 1, and then add them to the twin-screw extruder, and select the screw combination 1 for melt mixing, that is, the screw combination sequence of the melting and plasticizing section of the extruder is 45 / 5 / 42 , 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42 L, in the mixing and dispersing section The screw combination sequence is 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42, 52 / 52, 36 / 36, 45 / 5 / 42, 45 / 5 / 42, 45 / 5 / 42. The temperature of each section of the extruder is 200° C., the screw speed is 600 rpm, extruded and granulated to obtain a polypropylene composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com