Modified renewable high impact polystyrene special material for household appliances and preparation method thereof

A polystyrene and high-impact-resistance technology, which is applied in the field of modified and recycled high-impact polystyrene special materials for household appliances and its preparation, can solve the problems of complex production process and high production cost, and achieve good mechanical properties and long residence time. , The effect of stable extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

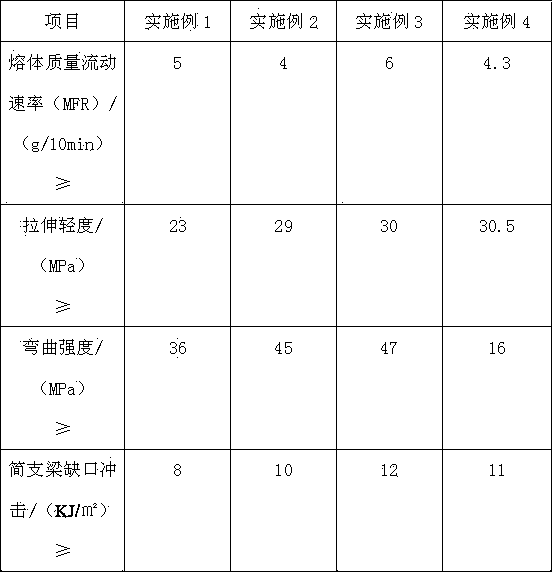

Embodiment 1

[0037] Modified recycled high-impact polystyrene special materials for home appliances, mainly composed of 20% polystyrene, 55% recycled polystyrene, 10% toughening agent, 6% talcum powder, 5% calcium carbide, 1% impact modifier, 0.1% dicumyl peroxide, 0.4% antioxidant 1010, 0.5% silane coupling agent, 0.5% EVA wax, 0.5% stearic acid, 1% composition of pigments.

[0038] The specific preparation method is as follows:

[0039] First, waste polystyrene is crushed, washed, dried, and homogenized to obtain recycled polystyrene.

[0040] Add recycled polystyrene and other components into the batching machine, stir in the batching machine at high speed for 5 minutes and mix evenly, and then make the mixed material after mixing evenly. Put the mixed material into the twin-screw extruder, use the extruder to extrude the mixed material to make strips, and cut them into granules. The granular material is the finished product of the present invention.

Embodiment 2

[0042] The difference between this embodiment and Example 1 is that the percentage content of each component is different, and the percentage content of each component in the present embodiment is as follows:

[0043] 40% Polystyrene, 20% Recycled Polystyrene, 13% Toughener, 10% Talc, 10% Calcium Carbide, 2% Impact Modifier, 0.5% Diisoperoxide Propylbenzene, 1% antioxidant 1010, 1% silane coupling agent, 1% EVA wax, 1% stearic acid, 0.5% pigment, and the high-speed stirring time in the batching machine is 6 minutes.

Embodiment 3

[0045] The difference between this embodiment and Example 1 is that the percentage content of each component is different, and the percentage content of each component in the present embodiment is as follows:

[0046] 11% polystyrene, 63% recycled polystyrene, 6% toughener, 7% talc, 6% calcium carbide, 3% impact modifier, 0.3% diisoperoxide Propylbenzene, 0.7% antioxidant 1010, 0.8% silane coupling agent, 1.2% EVA wax, 0.6% stearic acid, 0.4% pigment, and the high-speed stirring time in the batching machine is 7 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com