Plate shearing machine capable of cutting multiple plates

A technology of shearing machine and plate, applied in the direction of nibbling cutting device, shearing device, shearing machine equipment, etc., can solve the problems of uneven shearing of multi-layer plates, waste of time, etc., and achieve simple structure , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

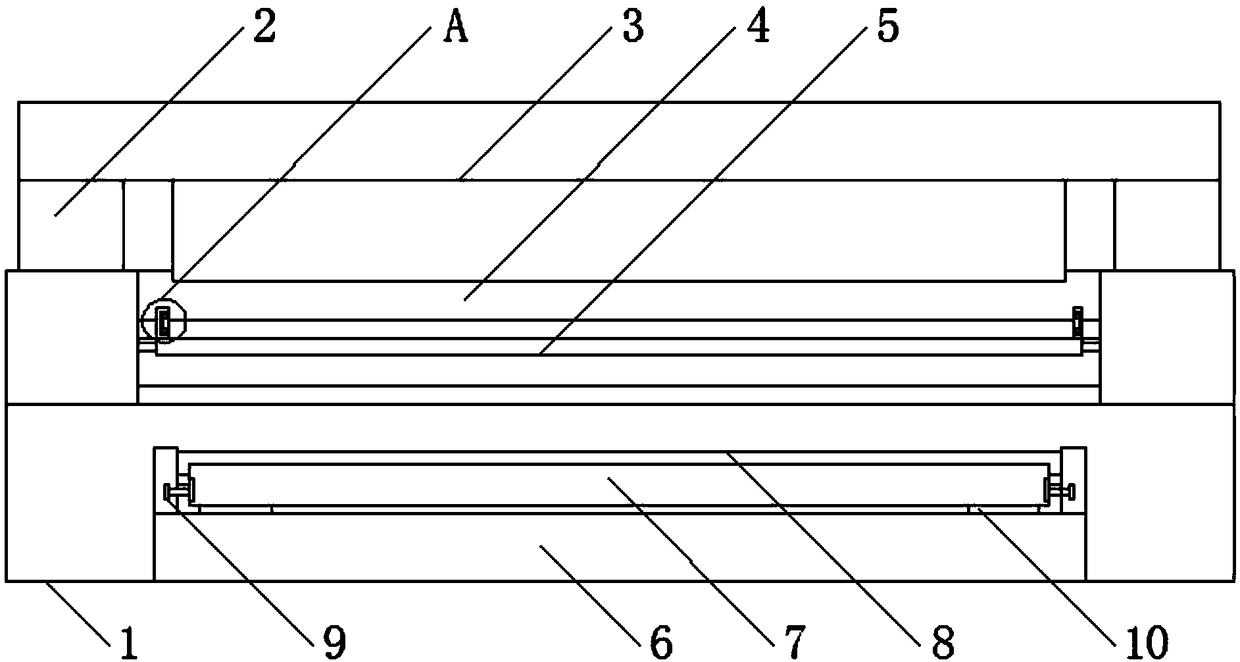

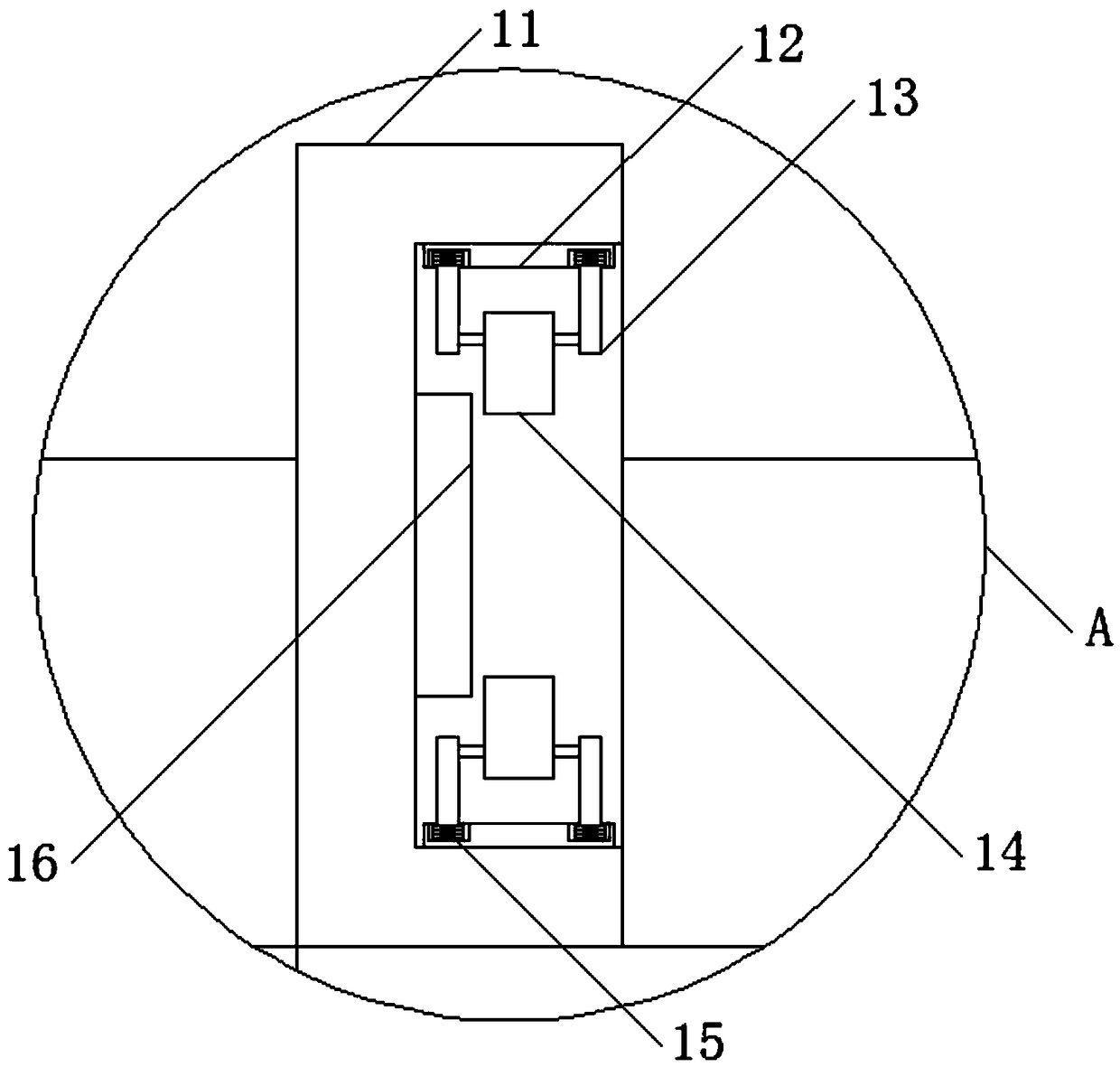

[0023] Embodiment: the multi-layer plate is placed on the conveying roller 4 at the same time for transmission. During the transmission, the multi-layer plate is limited and transmitted in the limit block 11 on the top of the limit plate 5. The position limit set in the limit block 11 The rollers 14 and the longitudinal pulleys 16 can press the multi-layer plates together through the telescopic spring 15 during the transmission of the multi-layer plates, and at the same time ensure that the multi-layer plates can continue to be transported. The shearing plate 3 lifts and reciprocates to cut the multi-layer plates, and the sheared plates slide down in the material receiving box 7 at the top of the receiving chute 6, and when the plates in the material receiving box 7 are stacked, push The plate 9 can conveniently stack the plates neatly, and the material receiving box 7 can be replaced, and the material receiving box 7 can be moved conveniently by the roller 10 on the material r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com