Biomass fuel crusher

A technology of biomass fuel and crusher, which is applied in the direction of grain processing, etc., can solve the problems of inconsistent crushing speed, no significant improvement in crushing effect, and increased energy consumption, so as to reduce equipment investment, improve shearing effect, reduce energy consumption and Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

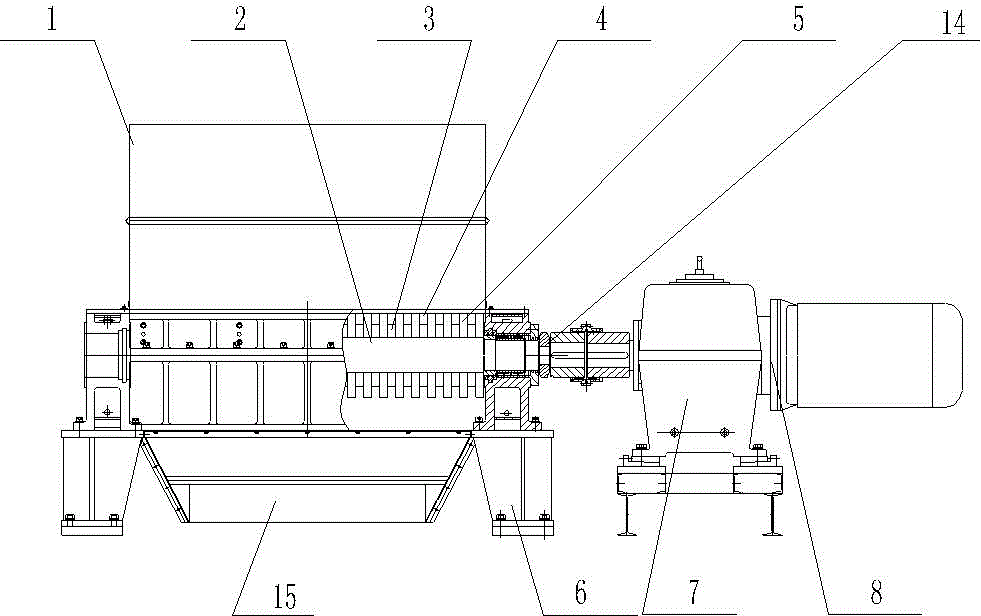

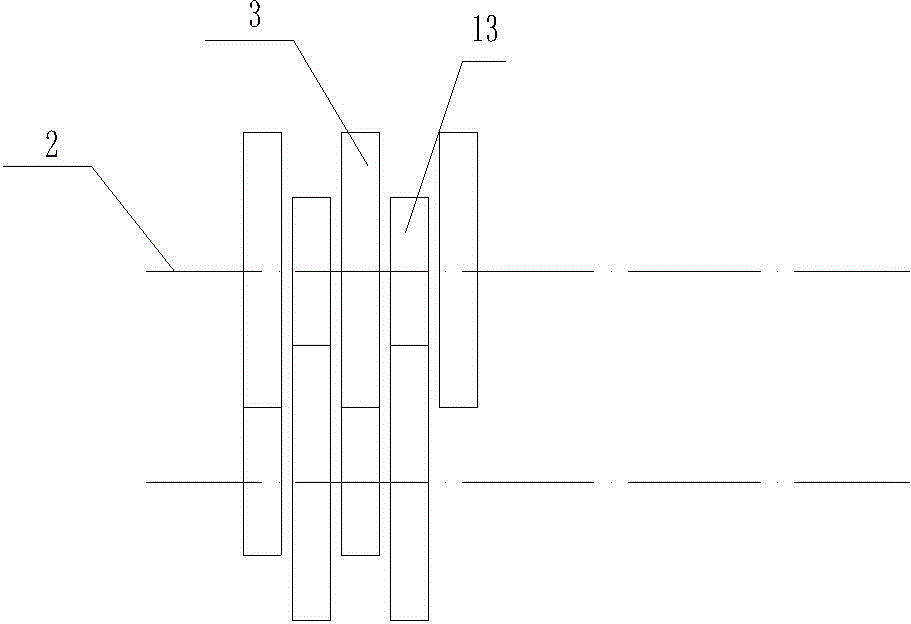

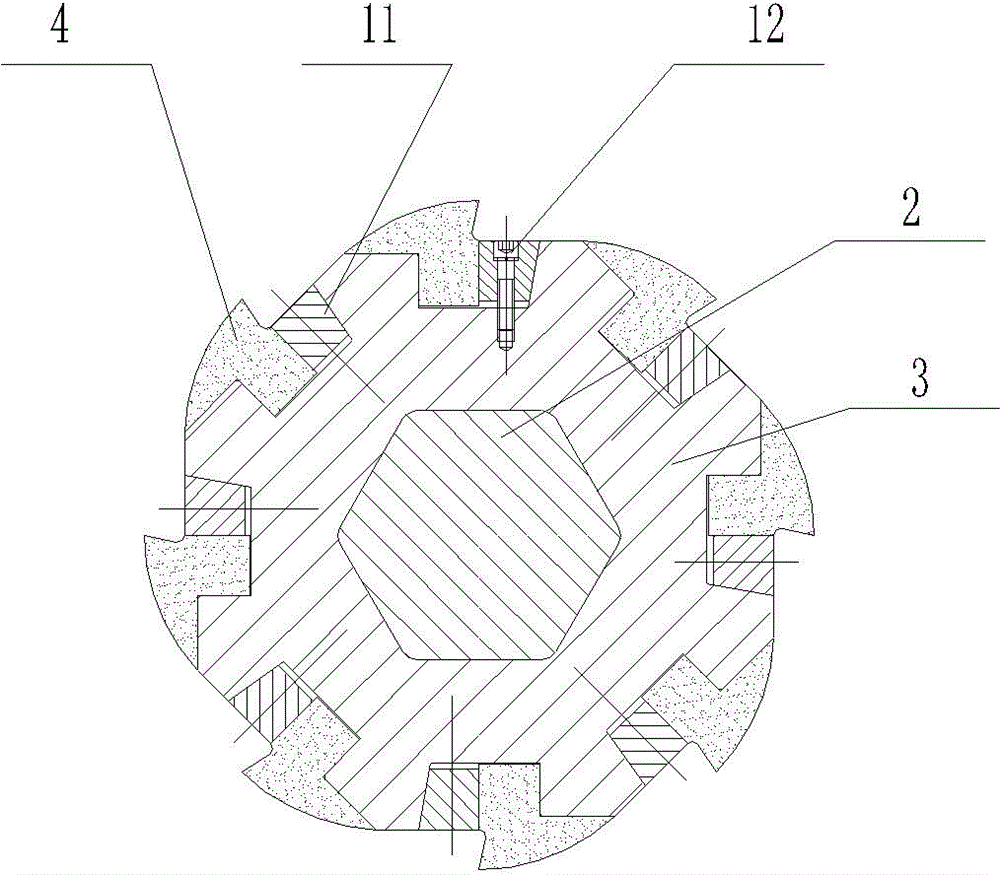

[0013] see figure 1 , The present invention includes a hopper 1, two knife shafts arranged side by side, including a driving knife shaft 2 and a driven knife shaft ( figure 1 In the main view, only the active tool axis 2 can be seen. The active tool axis 2 and the driven tool axis are respectively mounted on the bracket 6 ( figure 1 In the main view, only one cutter shaft can be seen), the active cutter shaft 2 and the driven cutter shaft have a sprocket 14 ( figure 1 In the main view, only one sprocket can be seen), the two sprocket gears are engaged, the sprocket 14 on the active cutter shaft 2 is connected to the reducer 7 through a coupling, and the reducer 7 is connected to the motor 8 at the outer end. , The two cutter shafts are respectively sleeved with cutter head 3, and the cutter heads 3 on the cutter shaft are embedded in each other and arranged axially at intervals (see figure 2 ), 13 is a spacer, which separates adjacent cutter heads and plays a role in positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com