Recovery device and recovery process of waste polyester bottle flakes

A technology of PET bottle flakes and recycling device, which is applied in the direction of plastic recycling and recycling technology, can solve the problems of waste of resources, damage to the equipment body of the cooking machine, pollution of the environment, etc., and achieves low corrosiveness and recycling of ethylene glycol easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

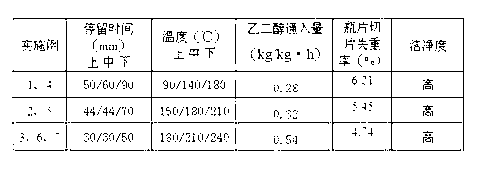

Embodiment 1

[0049] combine Figure 1~4 As shown, the recovery device for waste polyester bottle flakes includes a cleaning device 1 connected sequentially along the production line, a lifting device 24, a crusher 25, and a post-alcoholysis reactor 26, wherein the top of the cleaning device 1 is respectively provided with a feed inlet 5 and an air outlet 6; the bottom of the cleaning device 1 is provided with a discharge port 23; in the cleaning device 1, at least two funnel-shaped redistributors 7 are fixedly arranged at intervals from top to bottom, and the redistributor 7 divides the body 1 into upper and lower intervals. , middle and lower cavities (8, 9, 10); a rotating shaft 11 is set through the openings 13 of each redistributor, the upper end of the rotating shaft 11 is connected to the power unit 14 in transmission, and the lower end is connected to the supporting device fixed in the cleaning device 1 4 Rotational connection; short stirring blades 15 are set on the rotating shaft ...

Embodiment 2

[0052] The recovery device of waste polyester bottle flakes has the same structure as the recovery device of embodiment 1.

[0053] The difference between the recovery process of waste polyester bottle flakes and the recovery process of Example 1 is that the temperatures of the upper, middle and lower cavities (8, 9, 10) are respectively: 150°C, 180°C, and 210°C. The residence times are: 44 min, 44 min, 70 min, and the amount of ethylene glycol introduced is 0.32 kg / kg h; the temperature of the post-alcoholysis reactor 26 is 272 ° C, and the residence time is 60 min. Other steps are the same as The recovery process steps of embodiment 1 are the same.

Embodiment 3

[0055] The recovery device of waste polyester bottle flakes has the same structure as the recovery device of embodiment 1.

[0056] The difference between the recovery process of waste polyester bottle flakes and the recovery process of Example 1 is that the temperatures of the upper, middle and lower cavities (8, 9, 10) are respectively: 180°C, 210°C, and 240°C. The residence times are: 30 min, 30 min, and 55 min, and the amount of ethylene glycol introduced is 0.54 kg / kg h; the temperature of the post-alcoholysis reactor 26 is 290°C, and the residence time is 35 min. Other steps are the same as The recovery process steps of embodiment 1 are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com