Patents

Literature

60results about How to "No need for manual cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

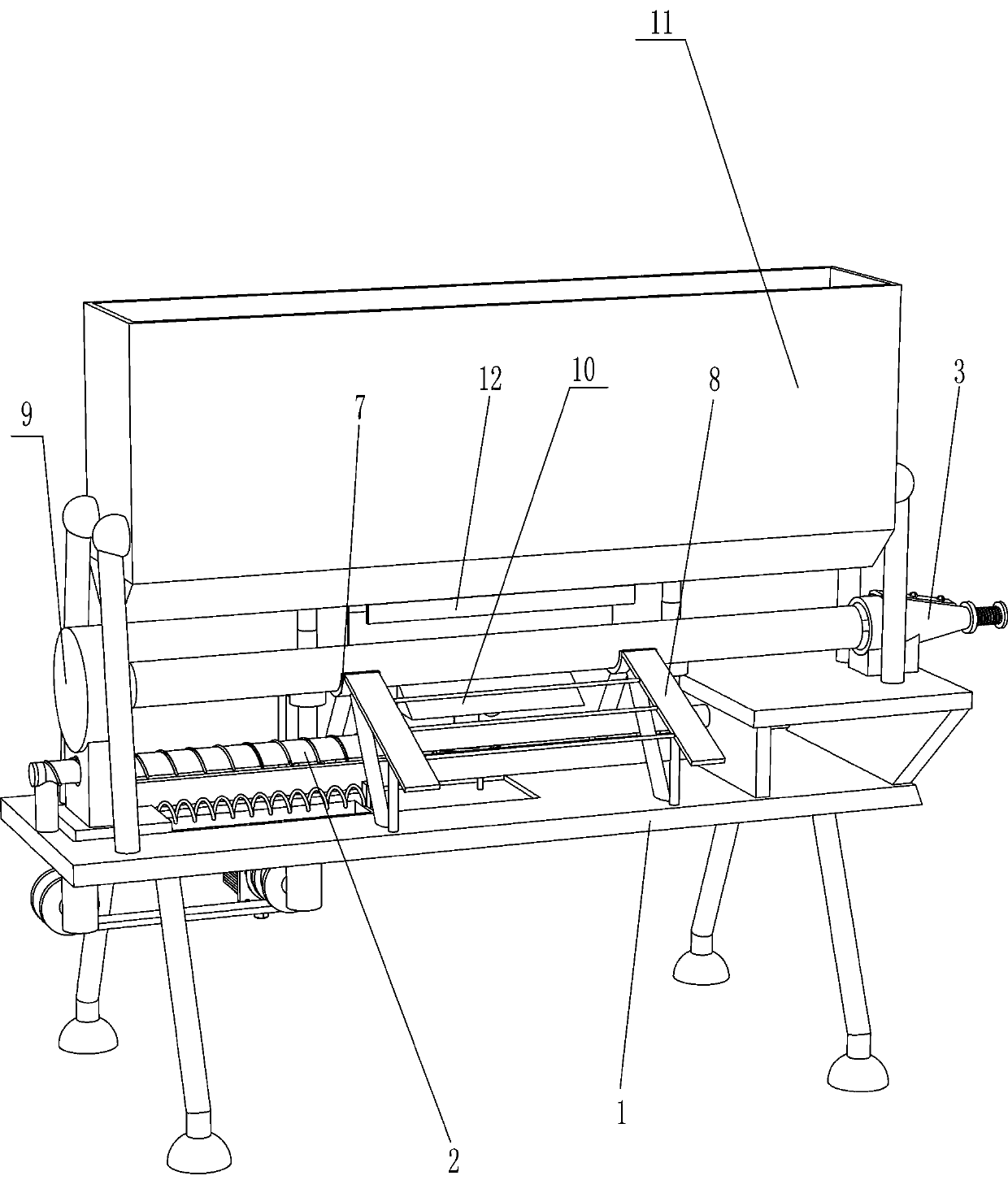

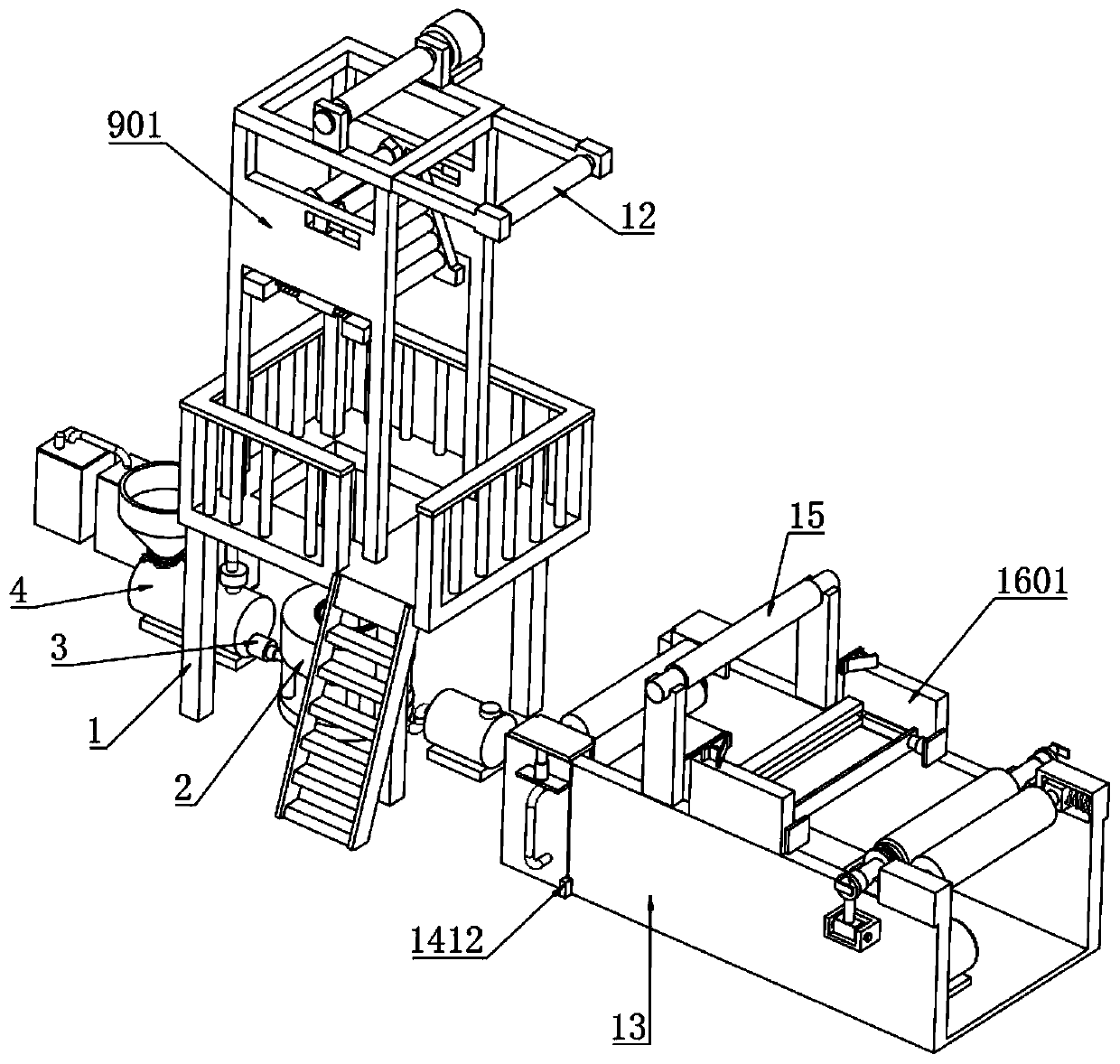

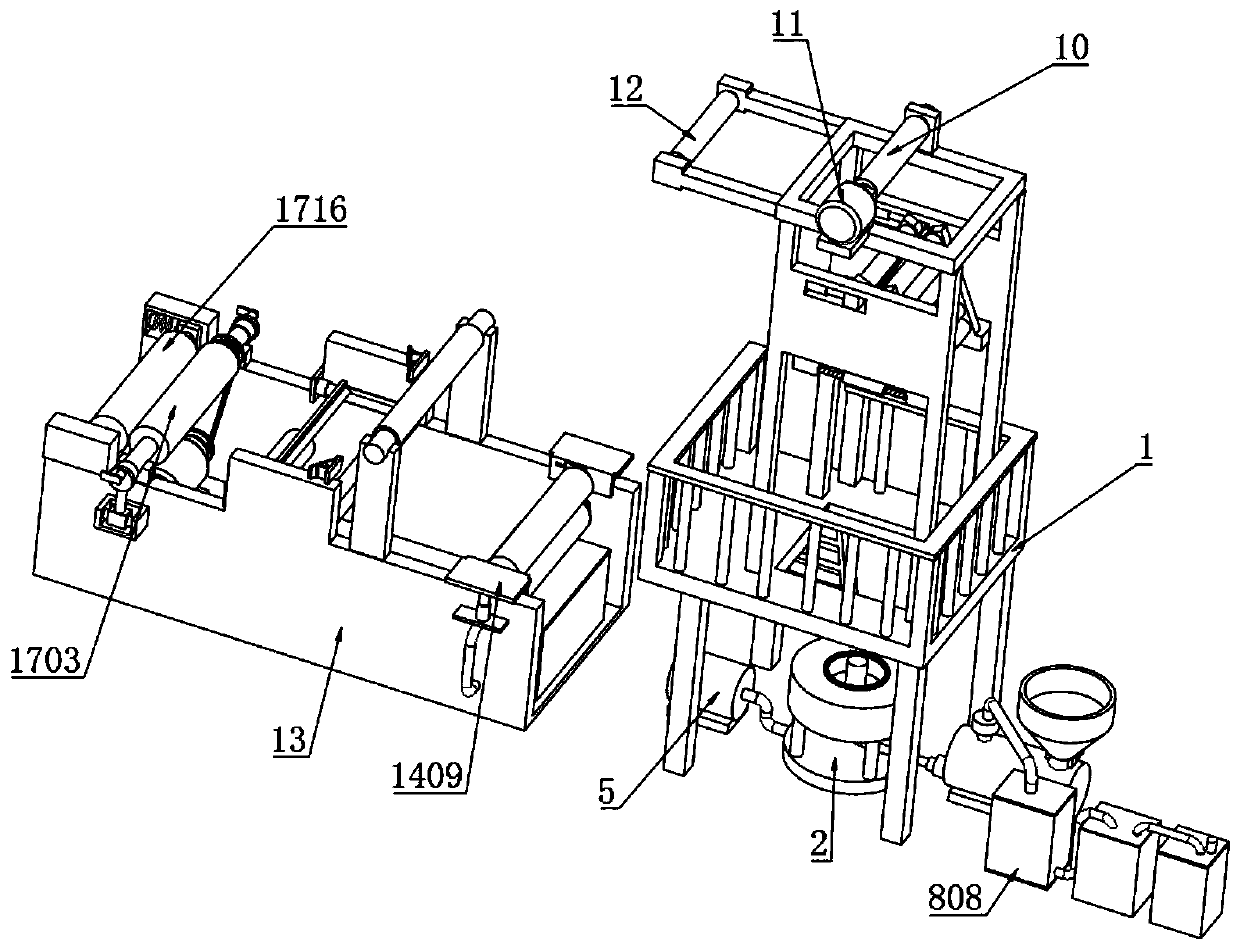

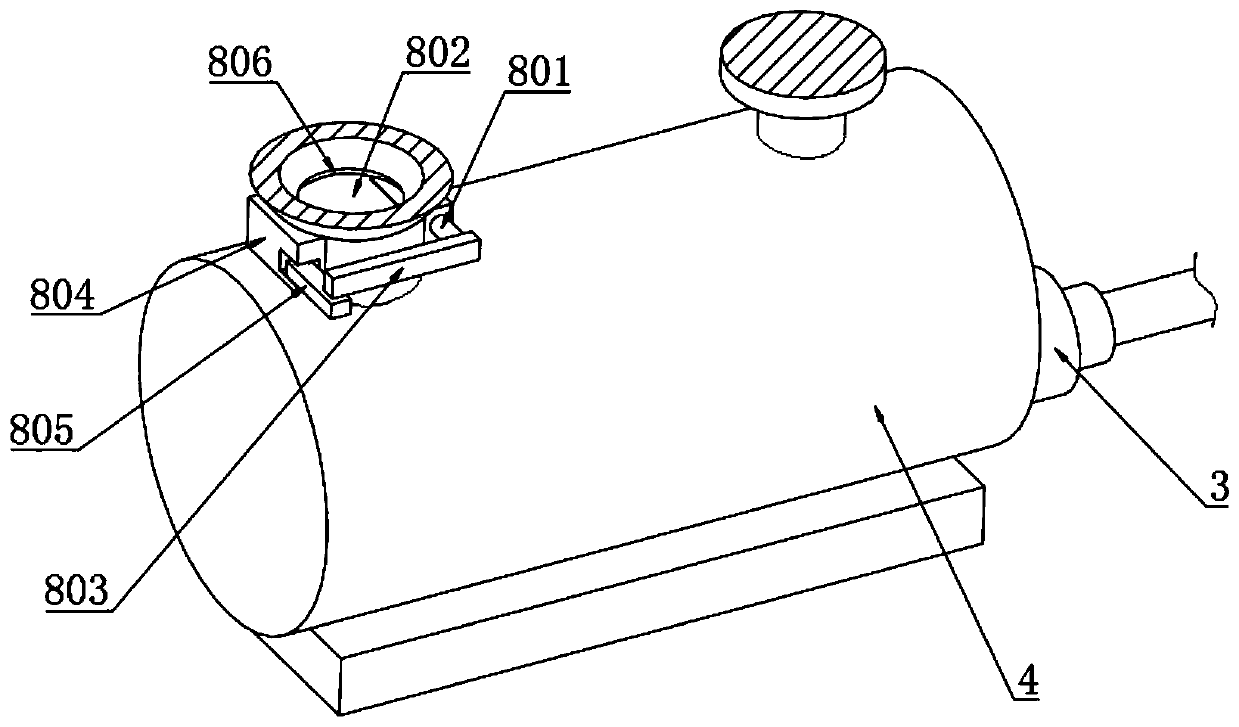

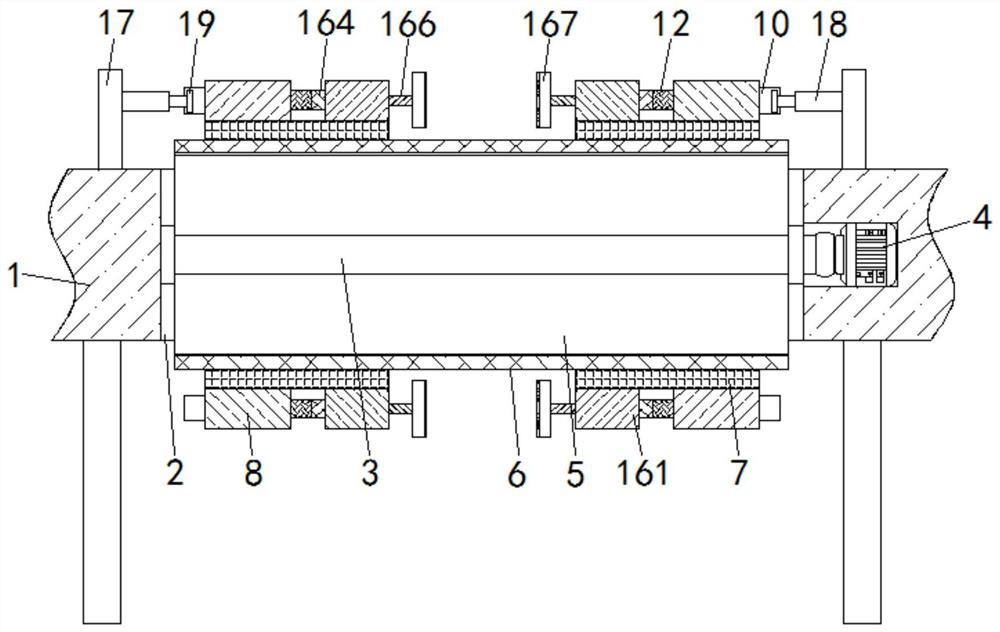

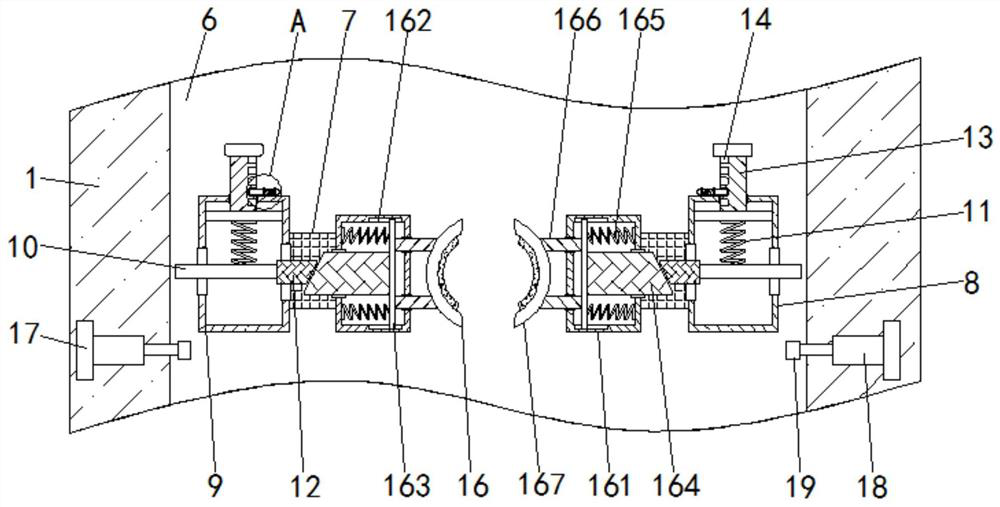

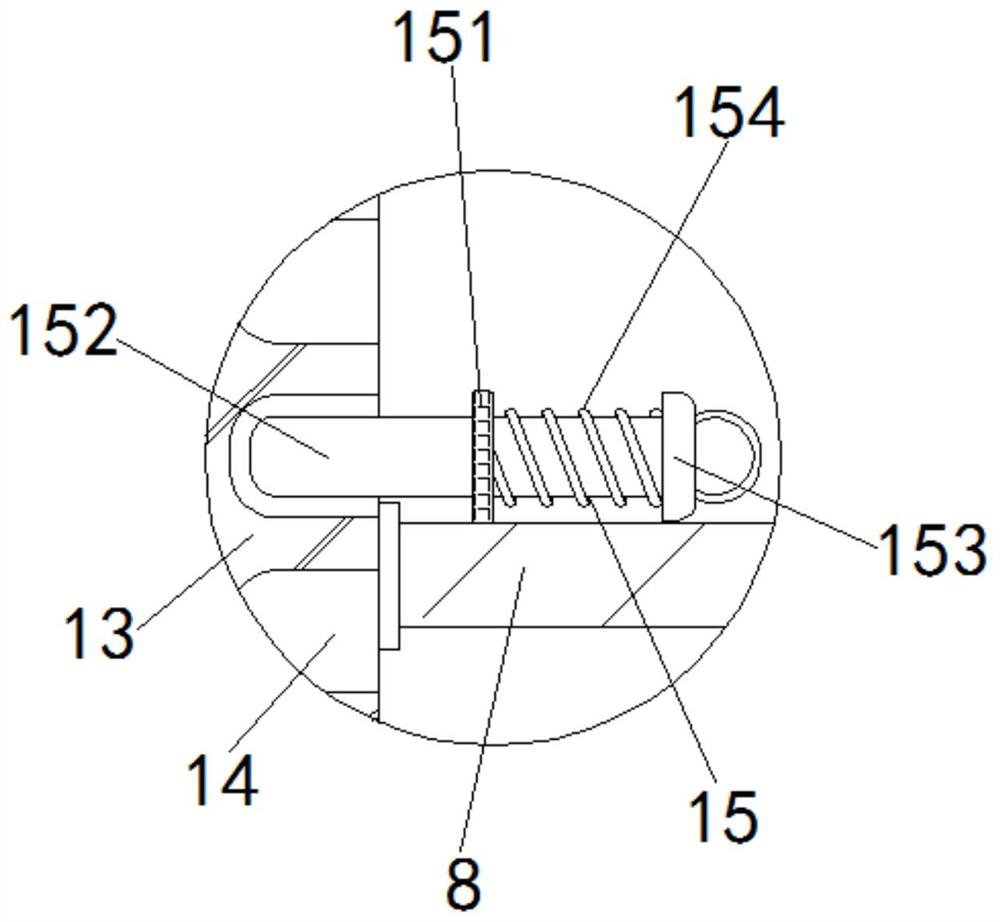

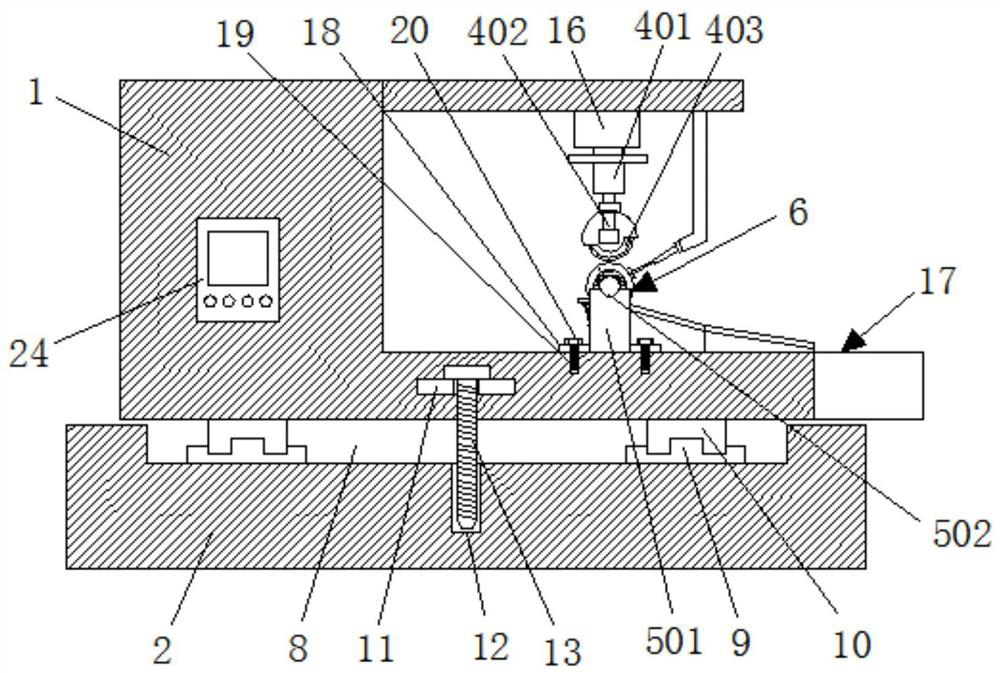

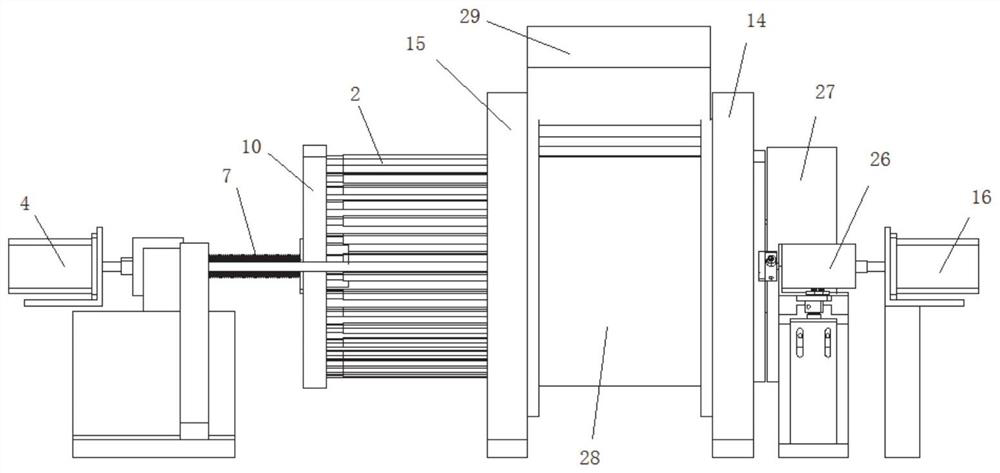

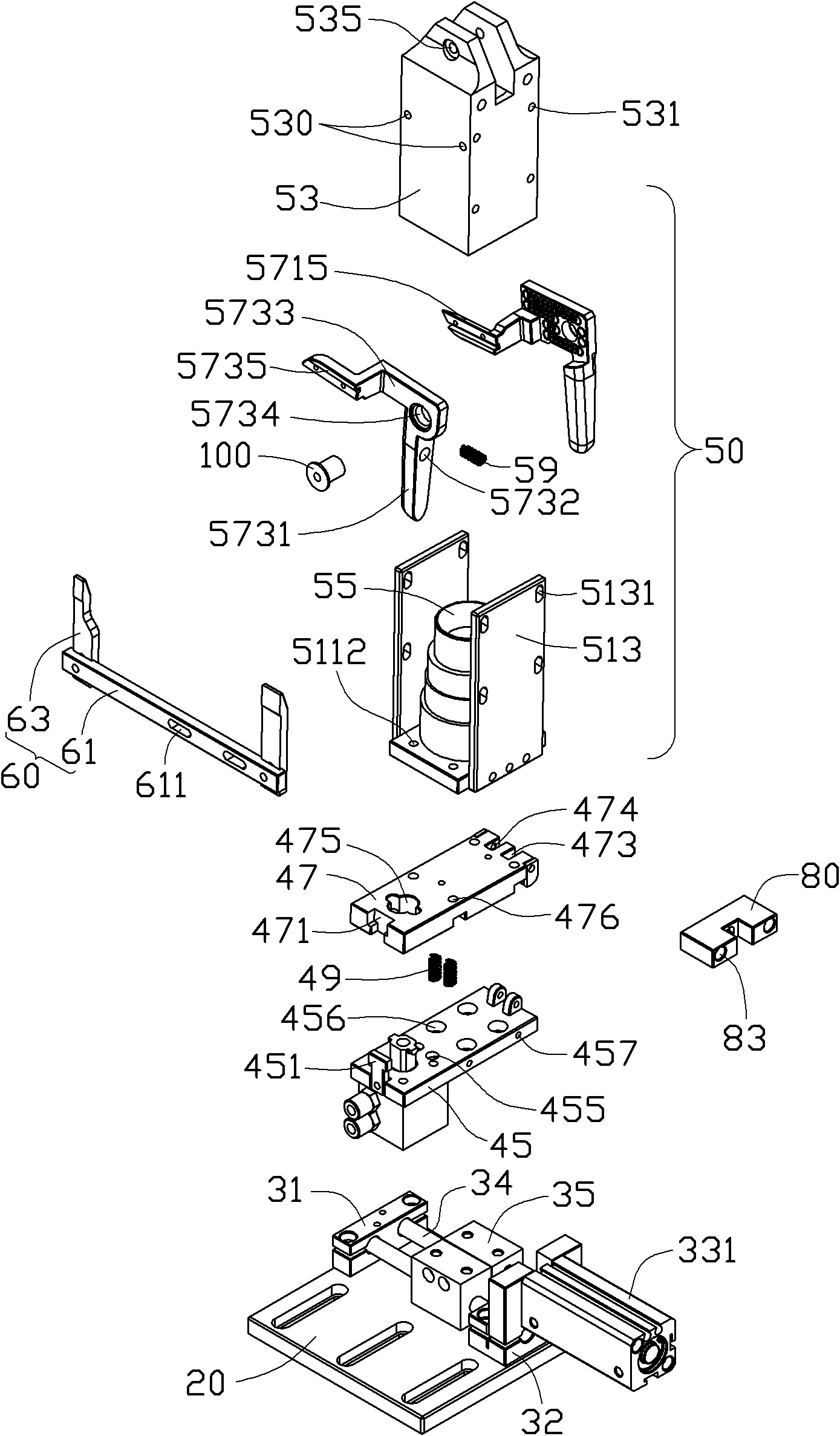

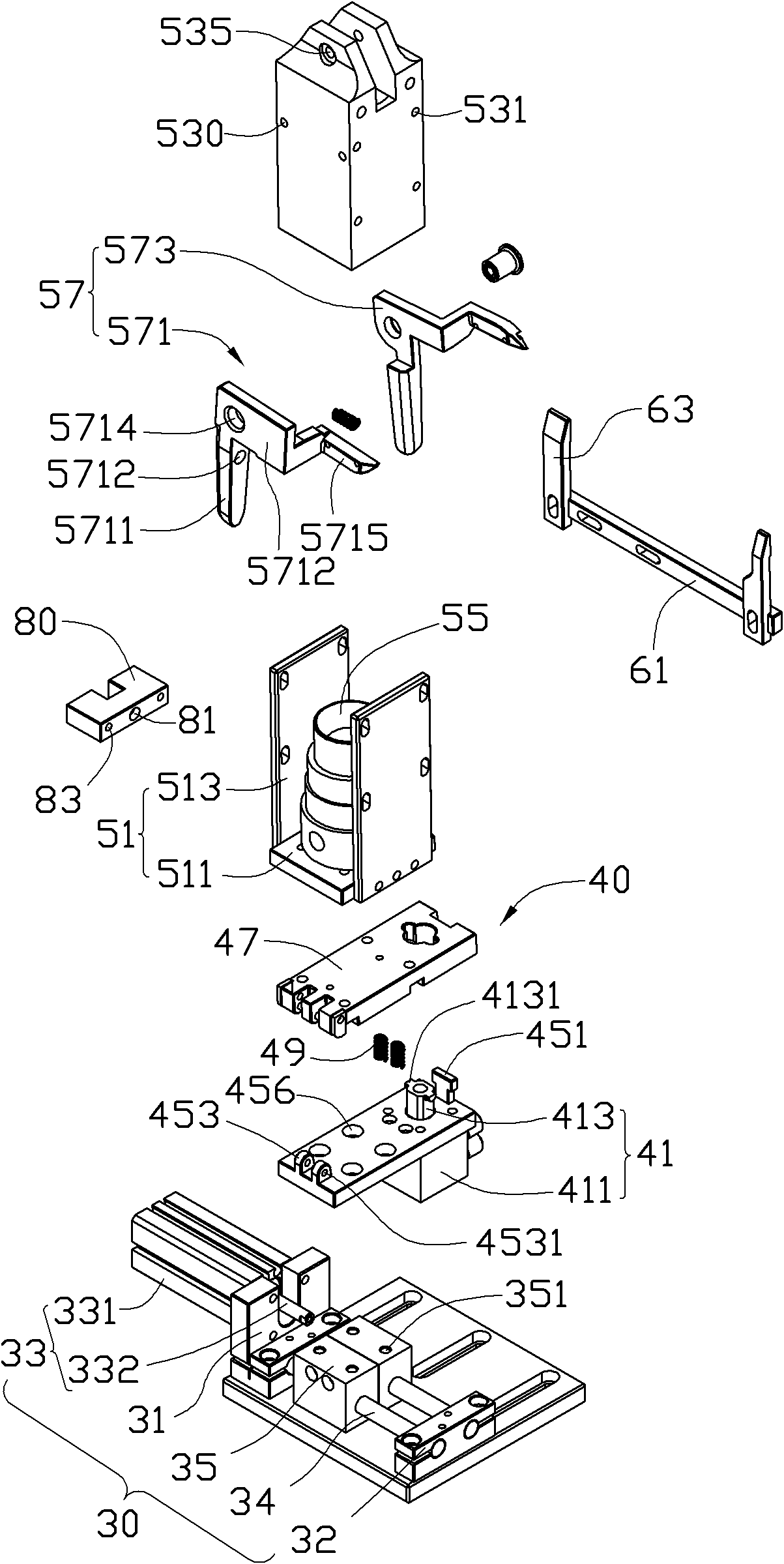

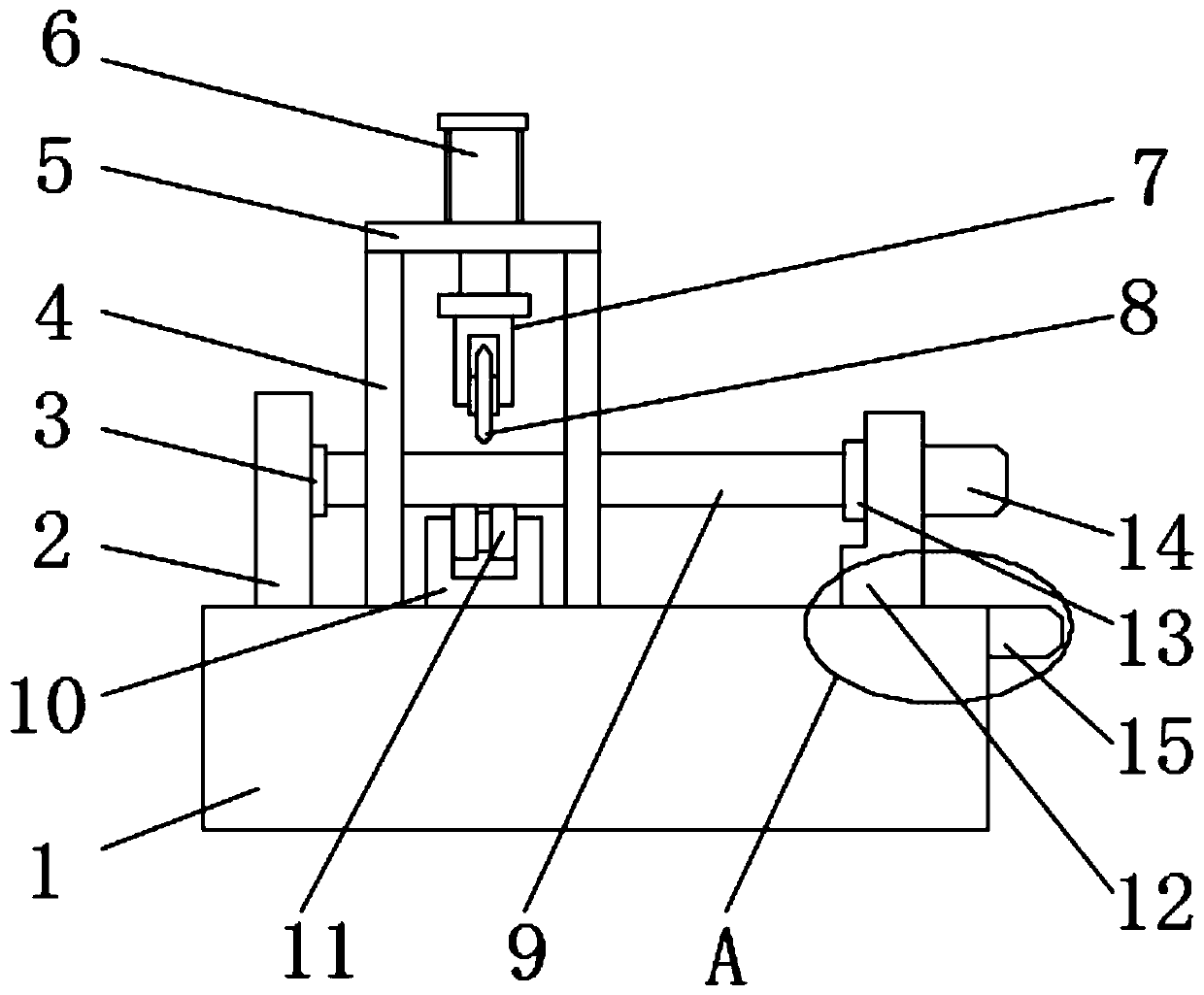

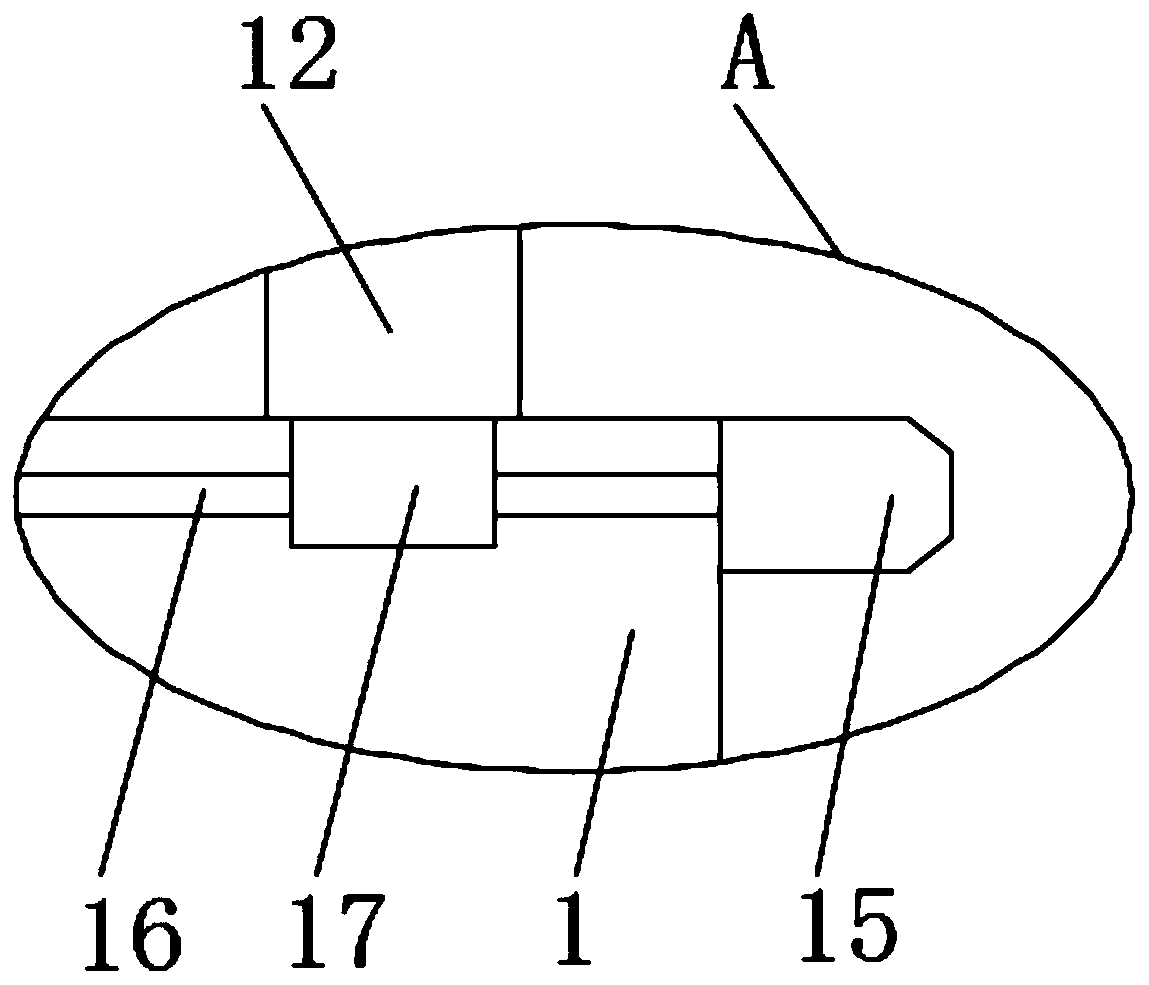

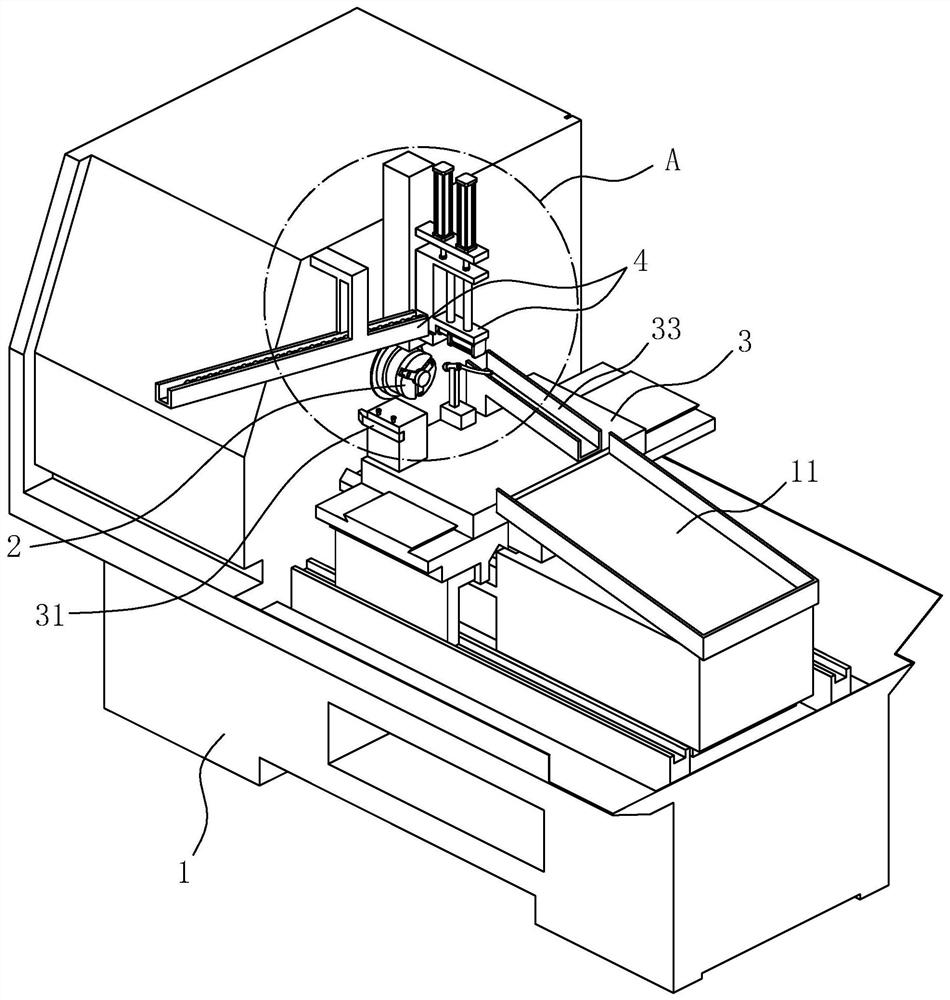

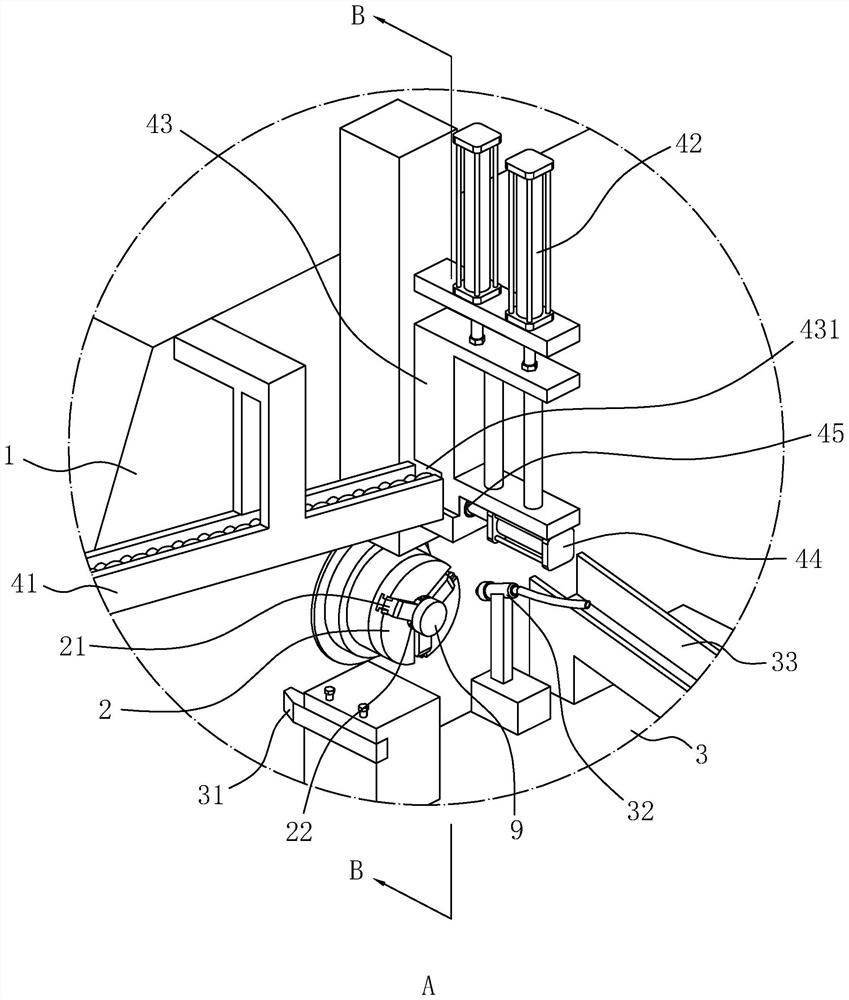

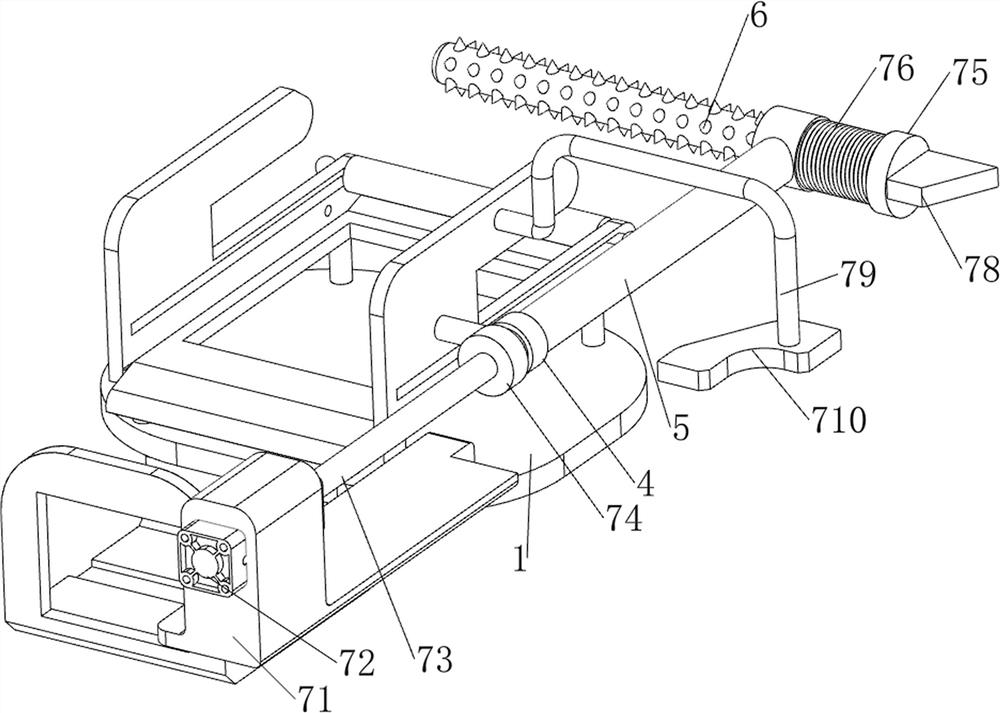

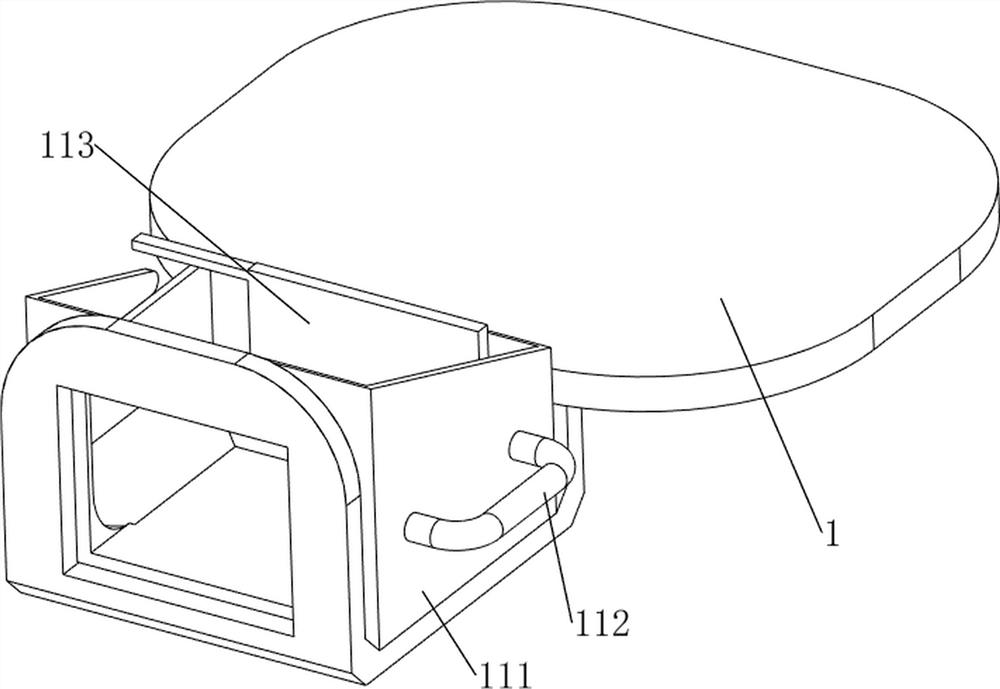

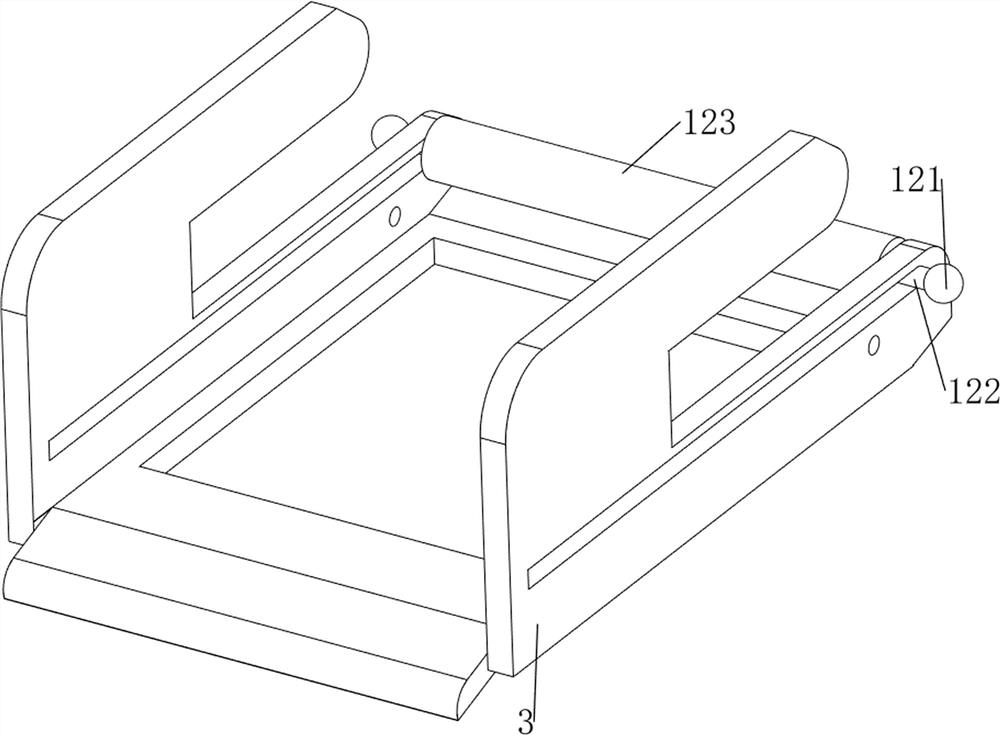

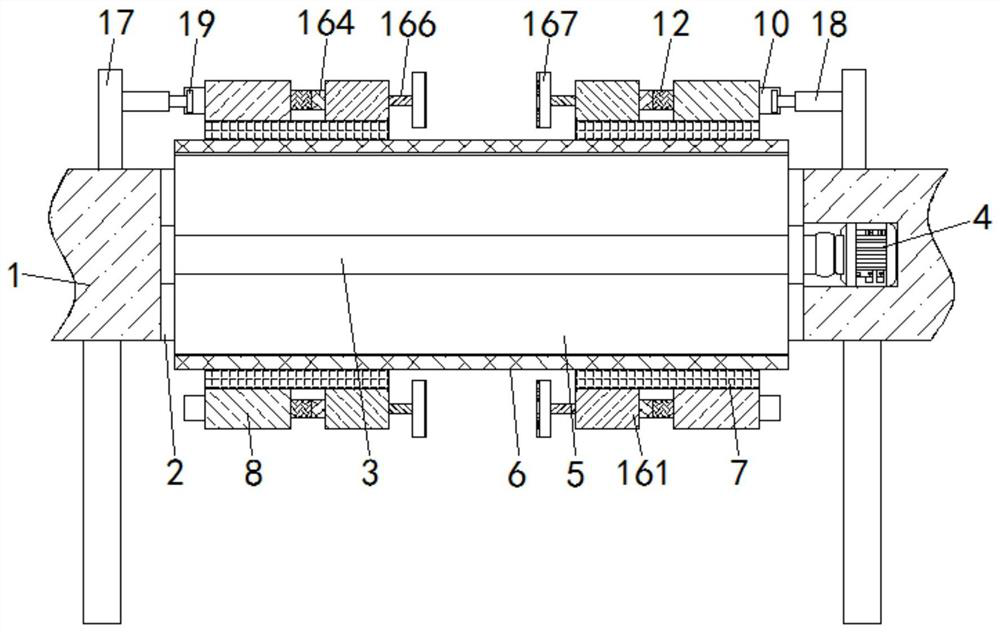

Special bidirectional automatic turning machine

ActiveCN110773751AImprove processing efficiencyRealize automatic unloadingFeeding apparatusMetal working apparatusButt jointEngineering

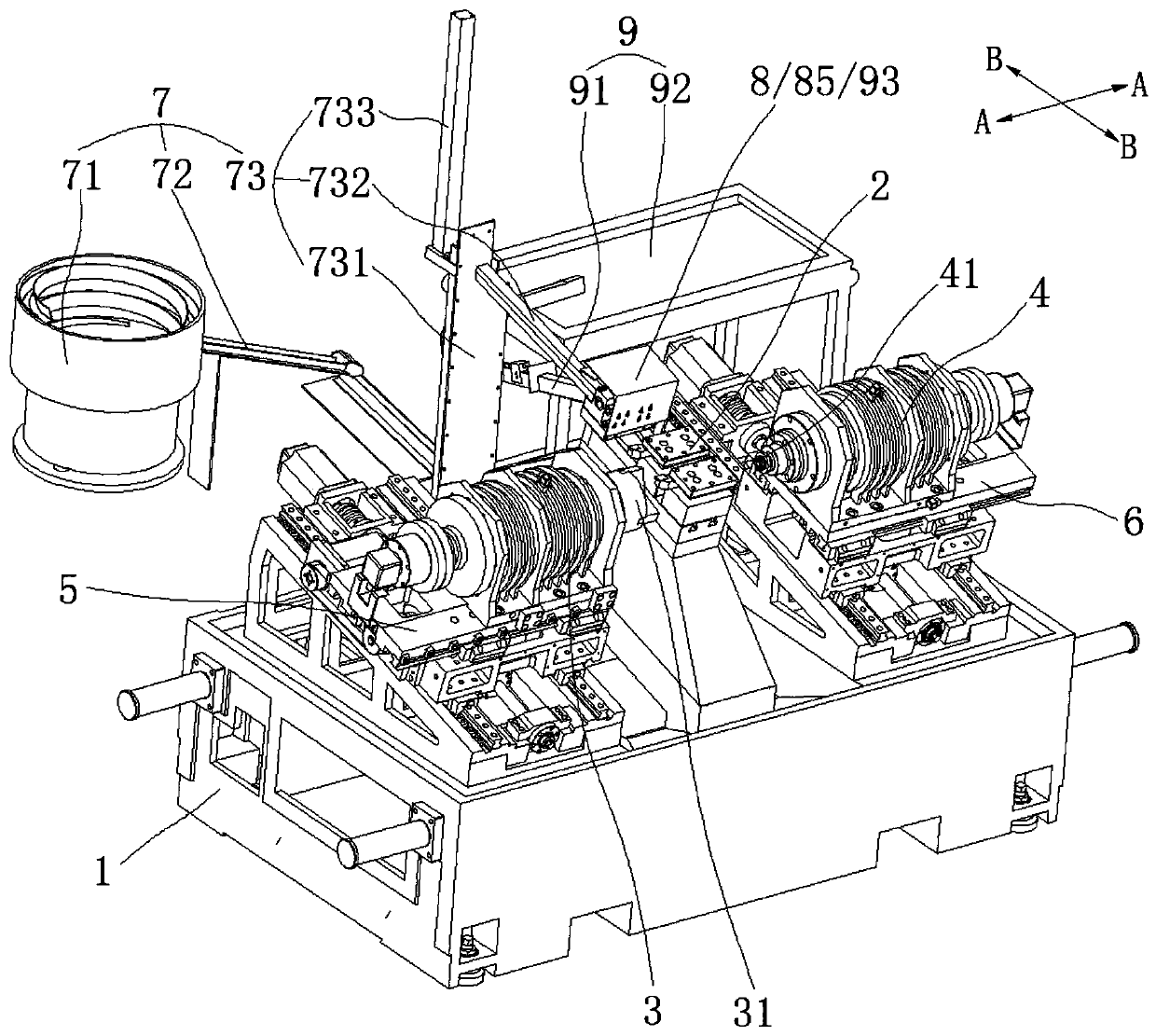

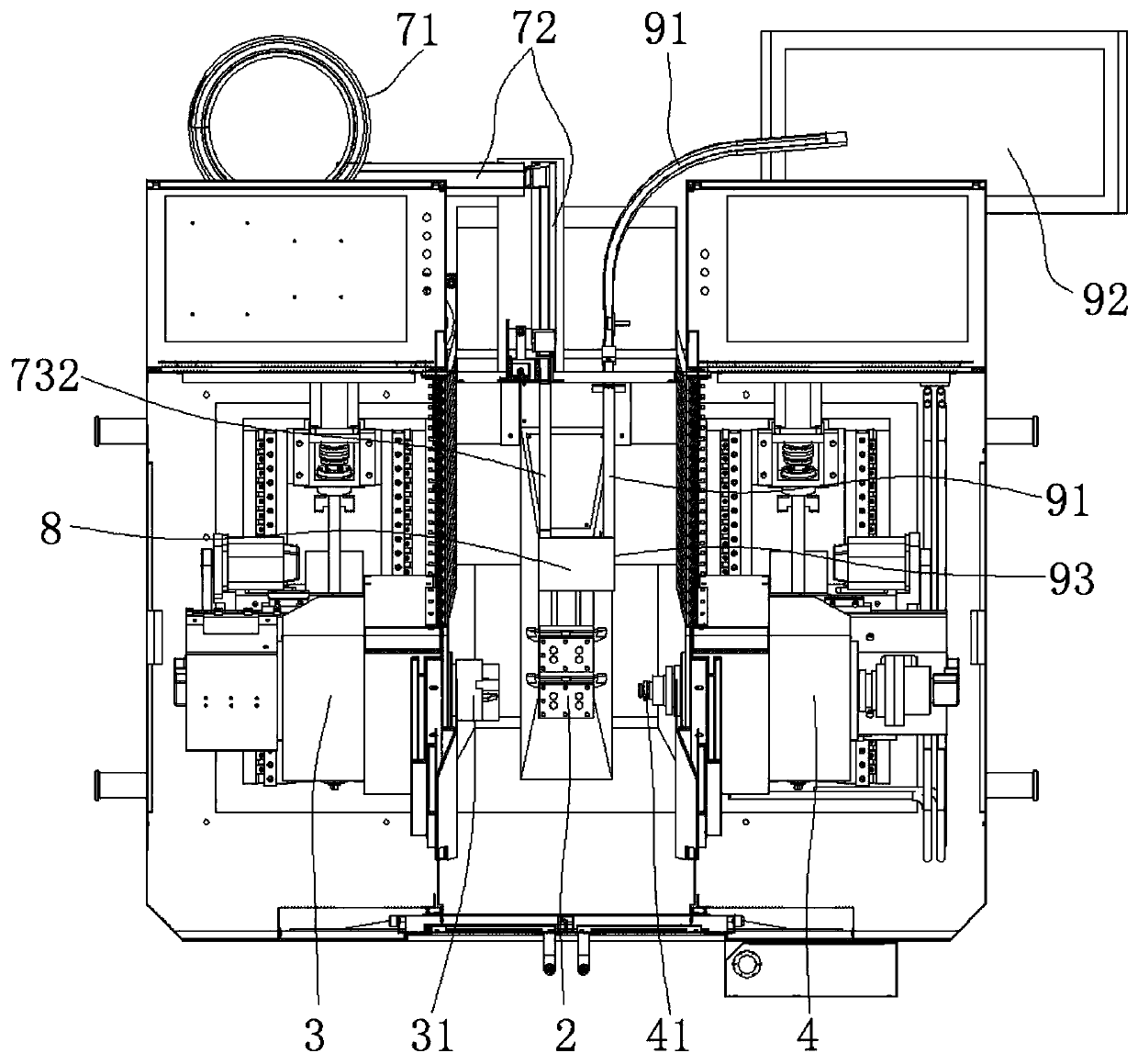

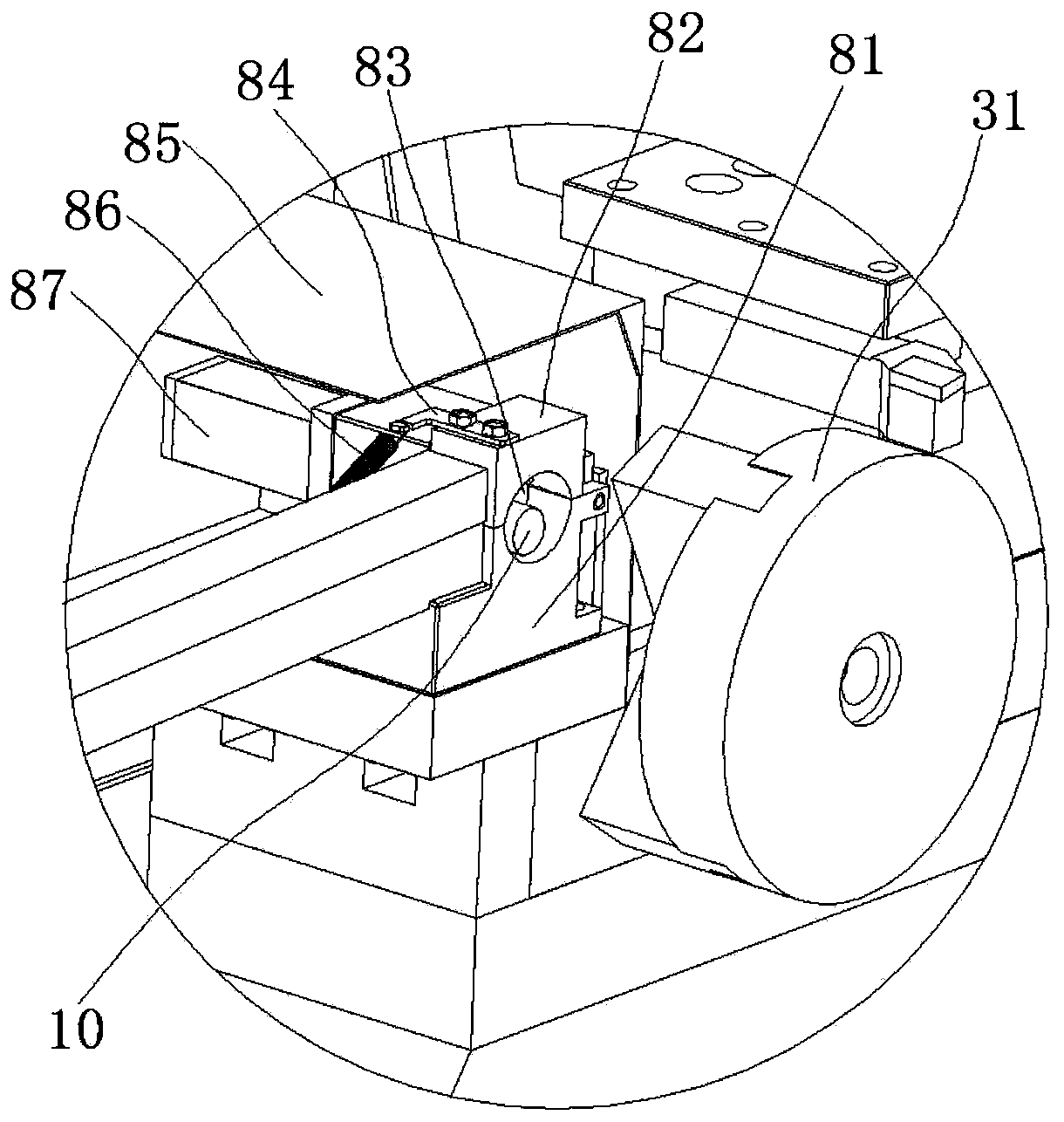

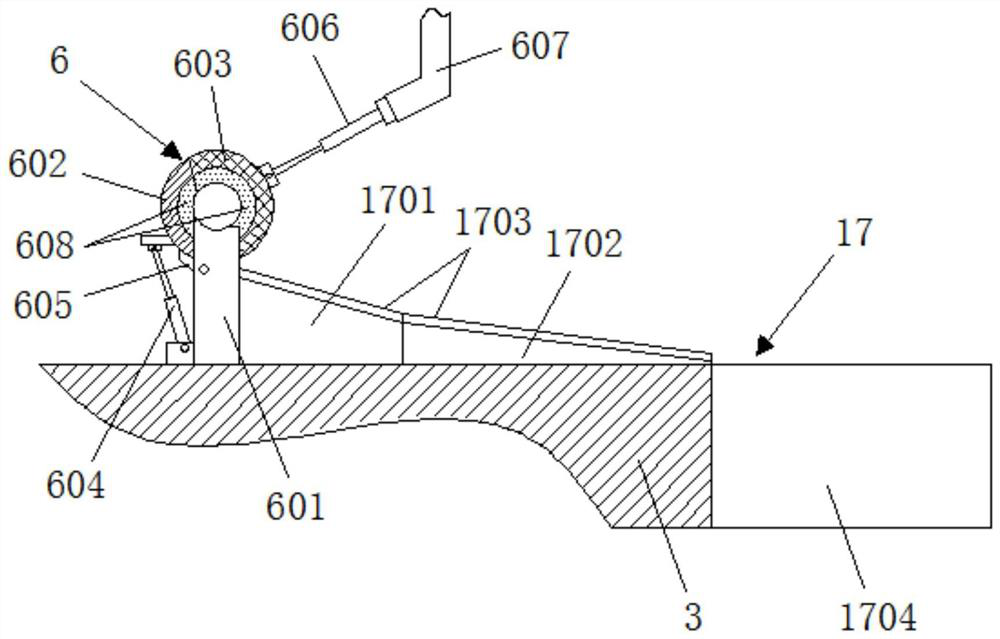

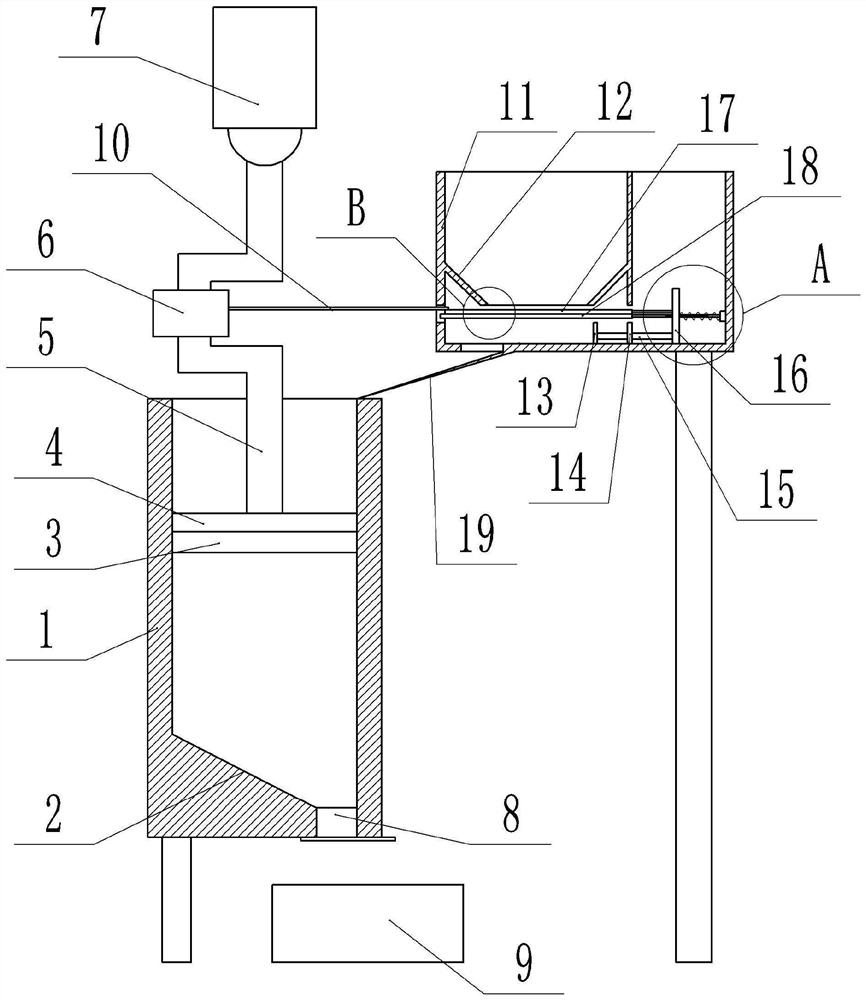

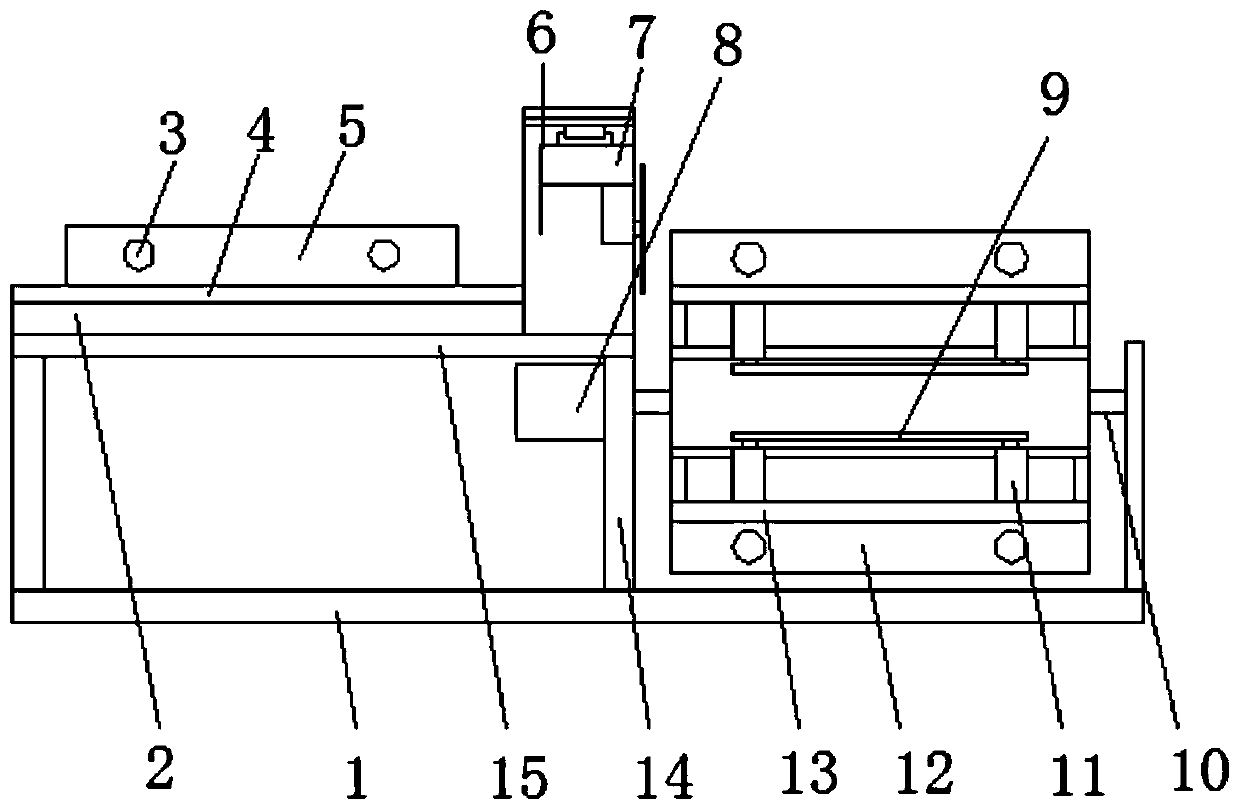

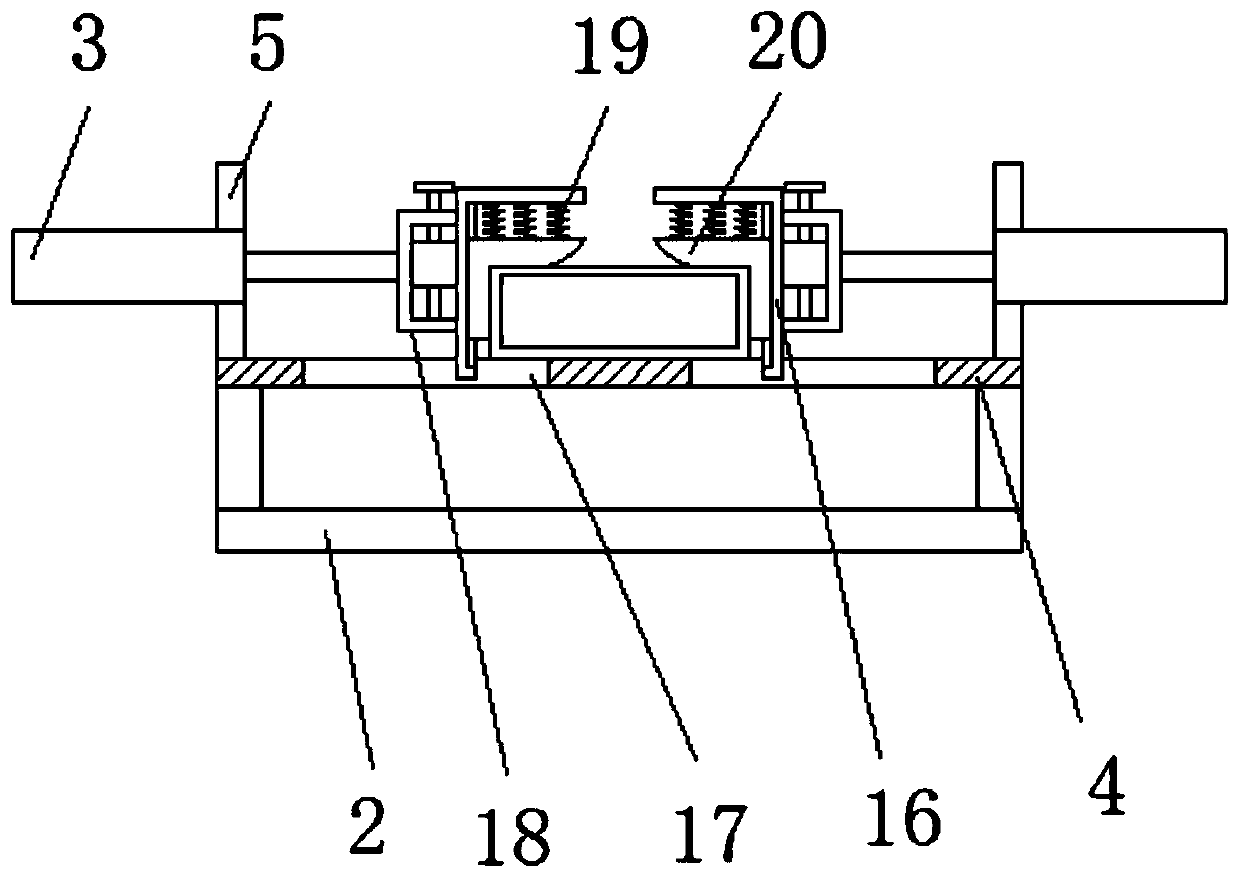

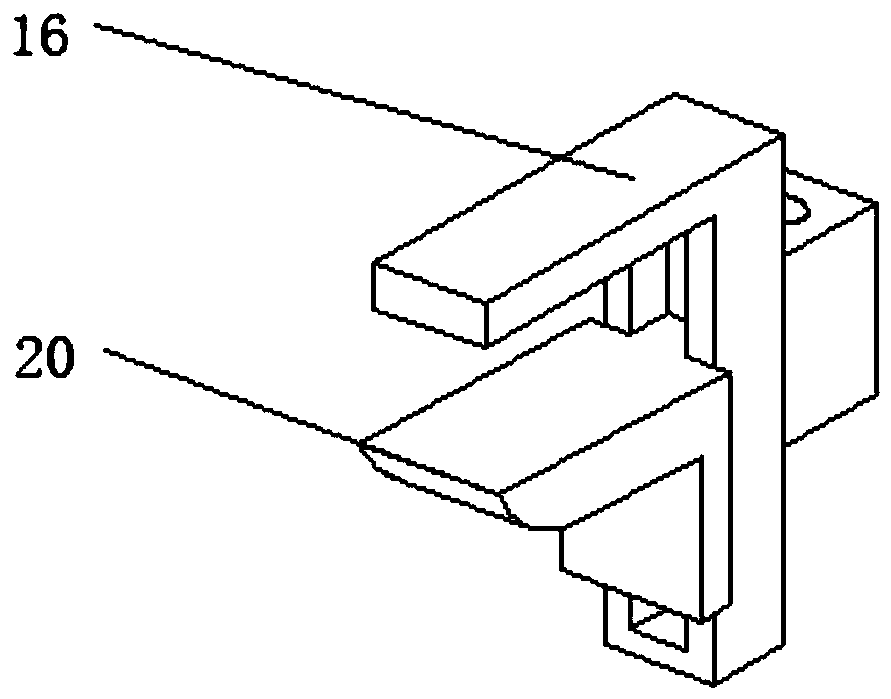

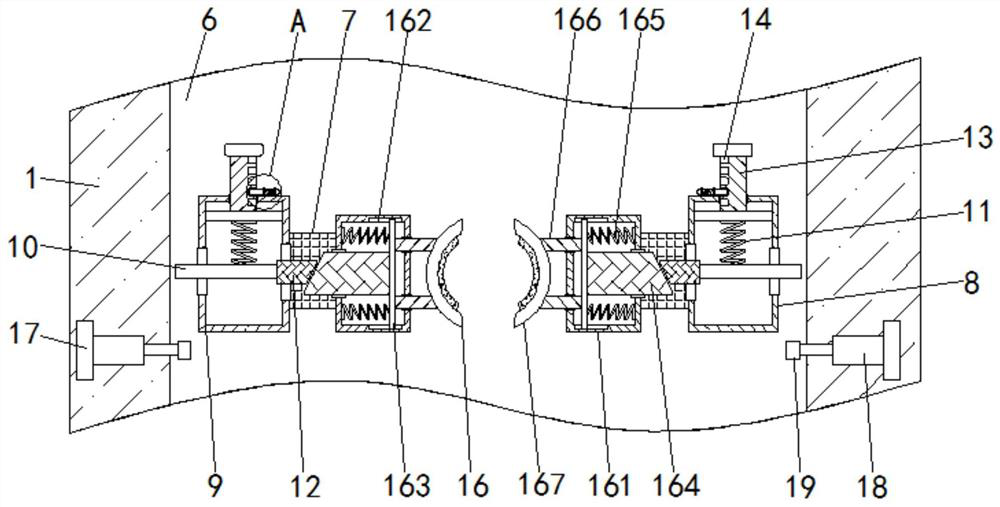

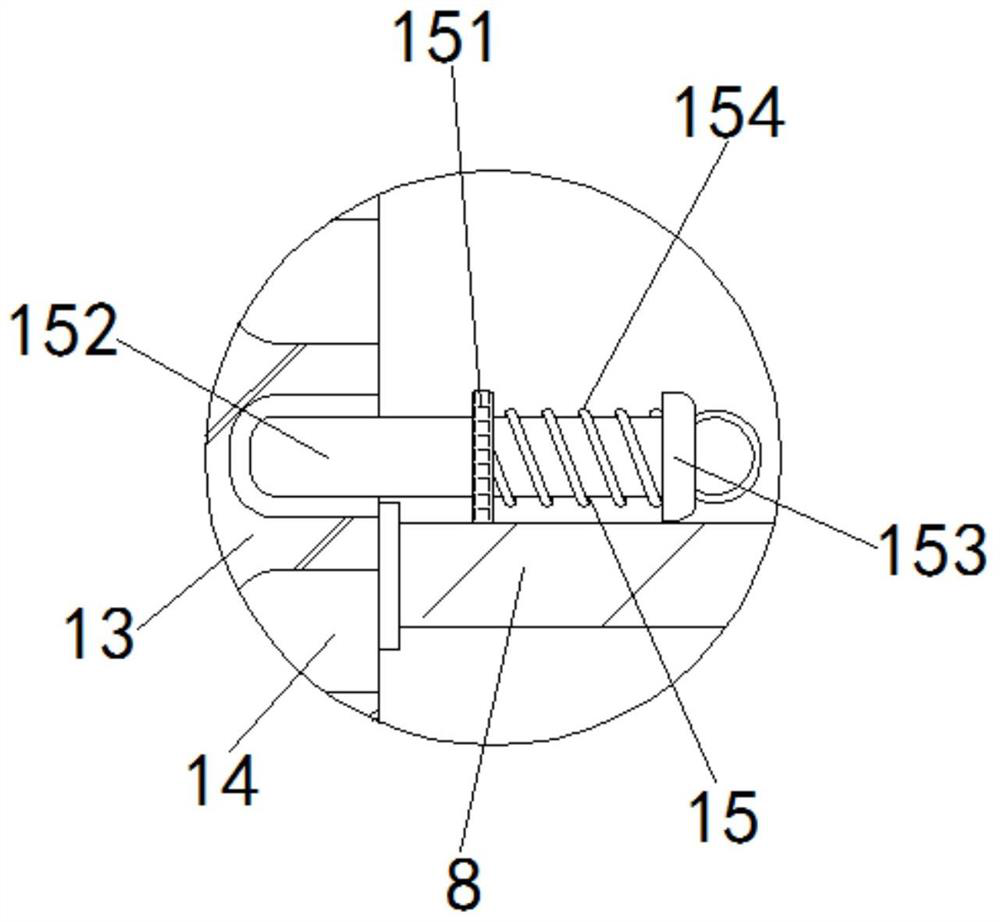

The invention provides a special bidirectional automatic turning machine. A tool rest is fixedly arranged on a lathe bed; a first spindle and a first transverse and longitudinal moving mechanism for driving the first spindle to move transversely and longitudinally is arranged on the left side of the tool rest; and a second spindle and a second transverse and longitudinal moving mechanism for driving the second spindle to move transversely and longitudinally is arranged on the right side of the tool rest. The special automatic turning machine further comprises a feeding mechanism, a pushing structure and a discharging mechanism. The special bidirectional automatic turning machine is high in automation degree, and labor intensity of people is reduced. After one end of a workpiece in a firstspindle chuck is machined, the workpiece is conveyed into a second spindle chuck through the moving and butt joint functions of the first spindle and the second spindle, and the other end of the workpiece in the second spindle chuck is machined, so that the two ends of the workpiece are machined through one-time clamping. Moreover, when the other end of the workpiece on the second spindle is machined, one end of a next workpiece on the first spindle can be machined at the same time, that is, the two workpieces can be machined at the same time, and the machining efficiency is high.

Owner:CHONGQING MACHINE TOOL GROUP

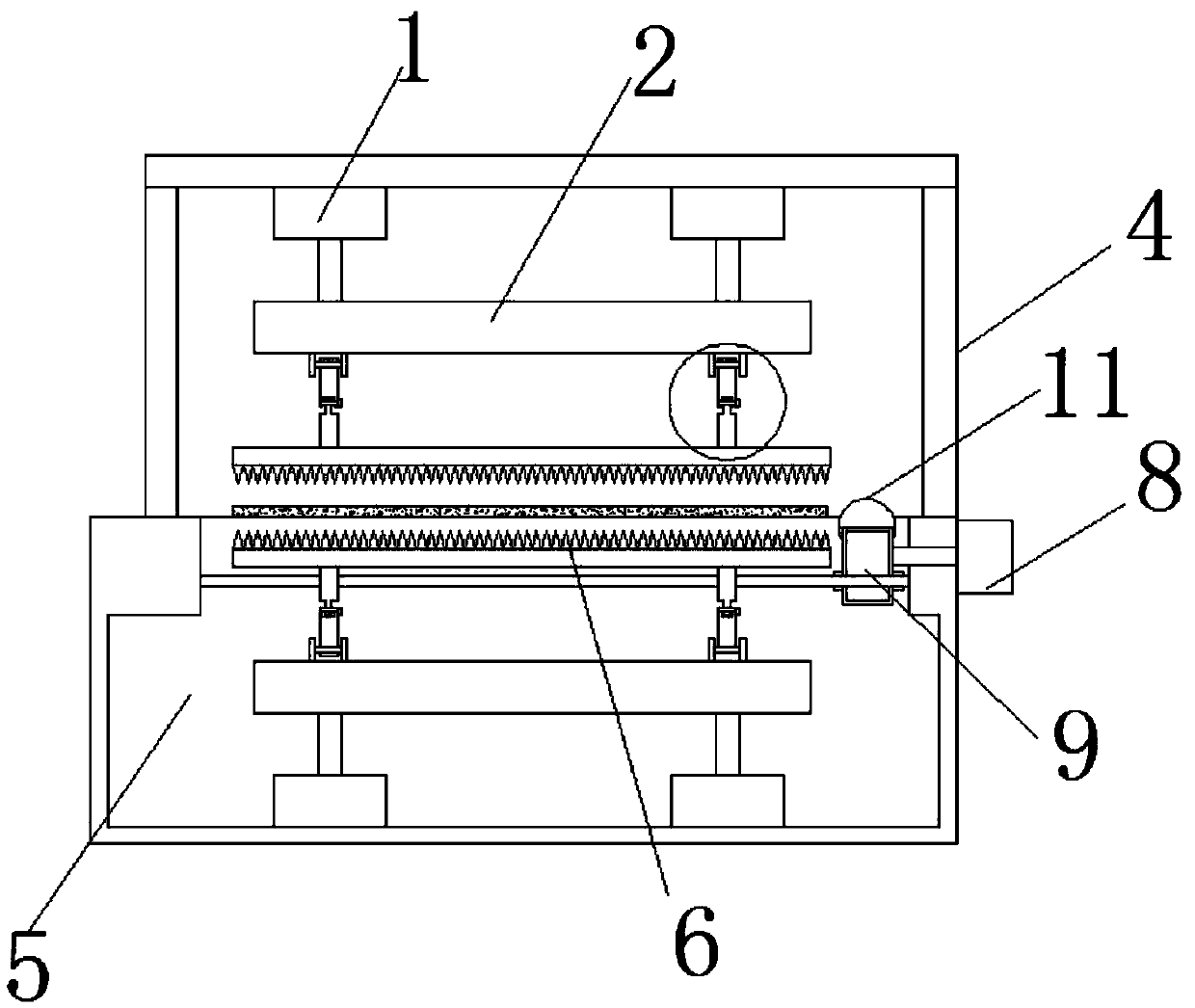

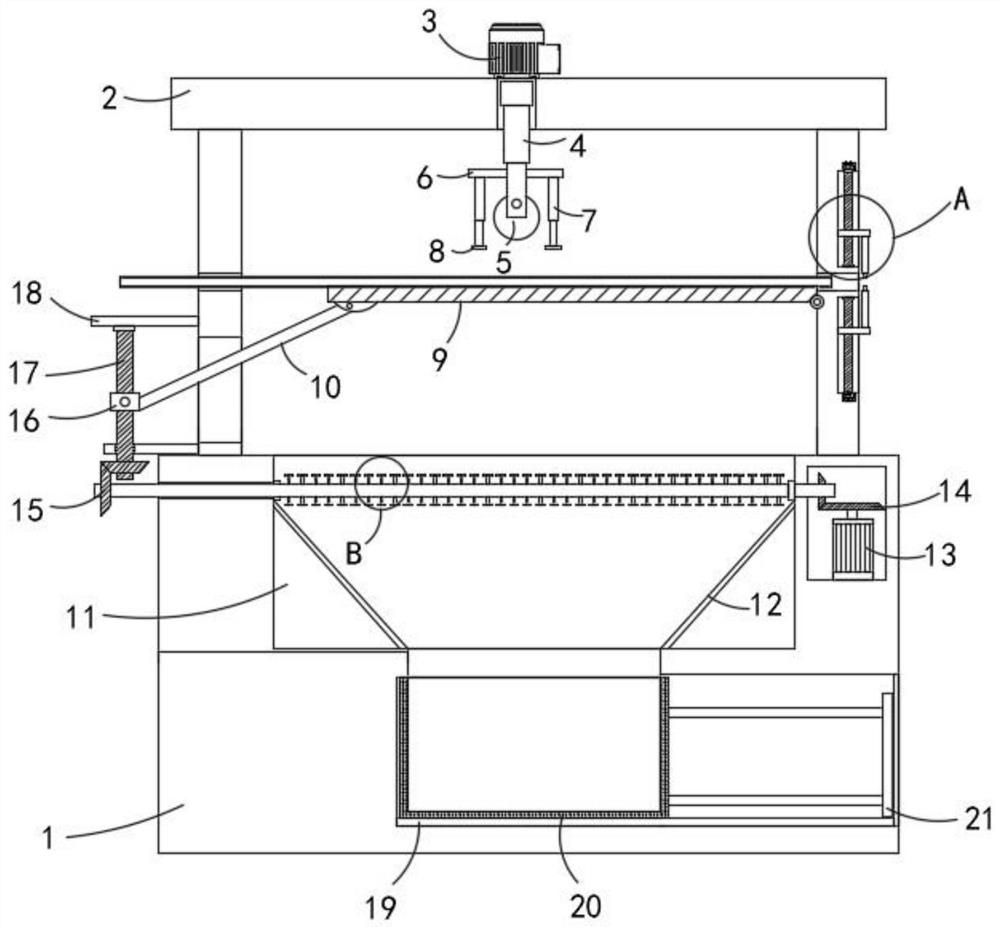

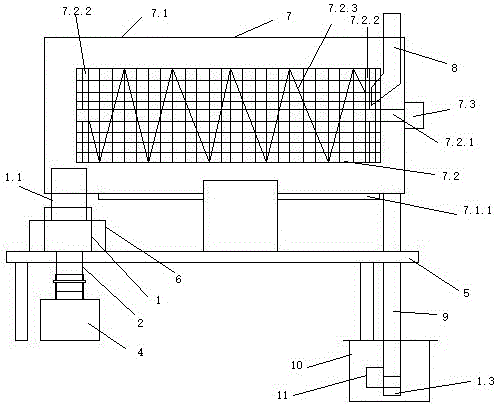

Metal rod fixed-length cutting device for manufacturing alloy milling cutter

InactiveCN112658389AImprove work efficiencyPrevent splashFeeding apparatusMagnetic separationMilling cutterGear wheel

The invention belongs to the technical field of milling cutter manufacturing, particularly relates to a metal rod fixed-length cutting device for alloy milling cutter manufacturing, and provides the following scheme for solving the problem that fixed-length cutting cannot be achieved: the metal rod fixed-length cutting device comprises a workbench, a bearing table and a top plate; a mounting box is horizontally welded to the middle of the bottom of the top plate; the middle of the mounting box is horizontally and rotatably connected with a lead screw; one end of the lead screw extends out of the mounting box and is provided with a driven gear; a forward and reverse motor is horizontally mounted at one corner of one side of the top plate; a driving gear is mounted at the top end of an output shaft of the forward and reverse motor; a push disc is slidably connected into a placing groove in the top of the workbench; a moving mechanism for driving the push disc to move is arranged in the mounting box; and a discharging table is welded to the other side of the bearing table; and a water tank is installed at the bottom between the workbench and the bearing table. Fixed-length cutting can be carried out on a metal rod, the working efficiency is improved, manual discharging is not needed, time and labor are saved, and sweeps are prevented from splashing.

Owner:邵阳县国安工具有限公司

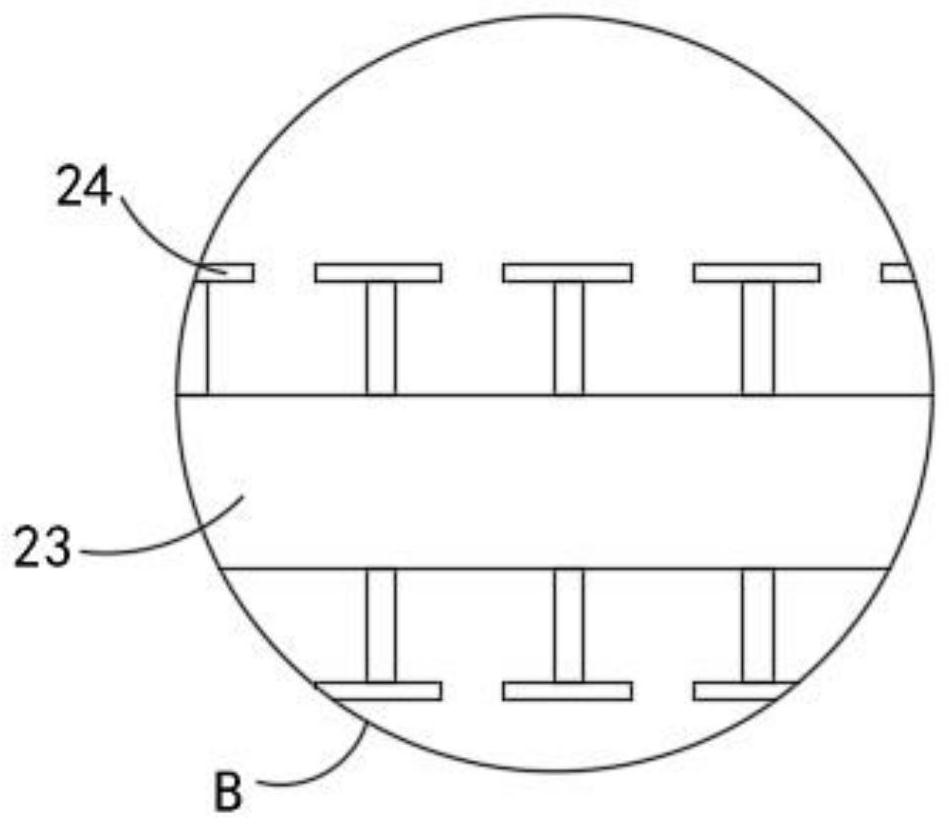

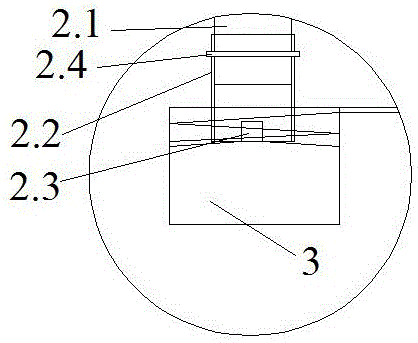

Wood stick sharpening equipment for garden fence construction

ActiveCN111331690AImprove work efficiencyReduce the difficulty of operationProfiling/shaping machinesTool bitMechanical engineering

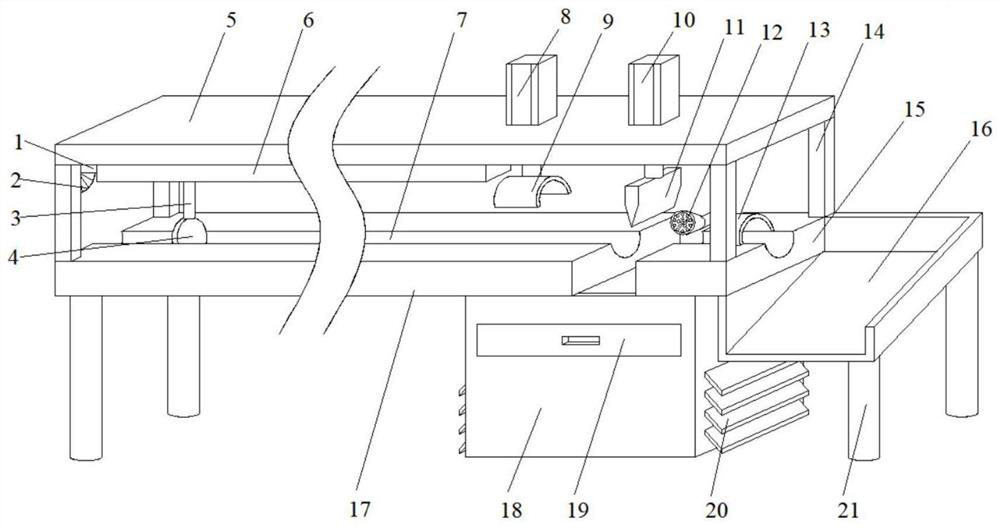

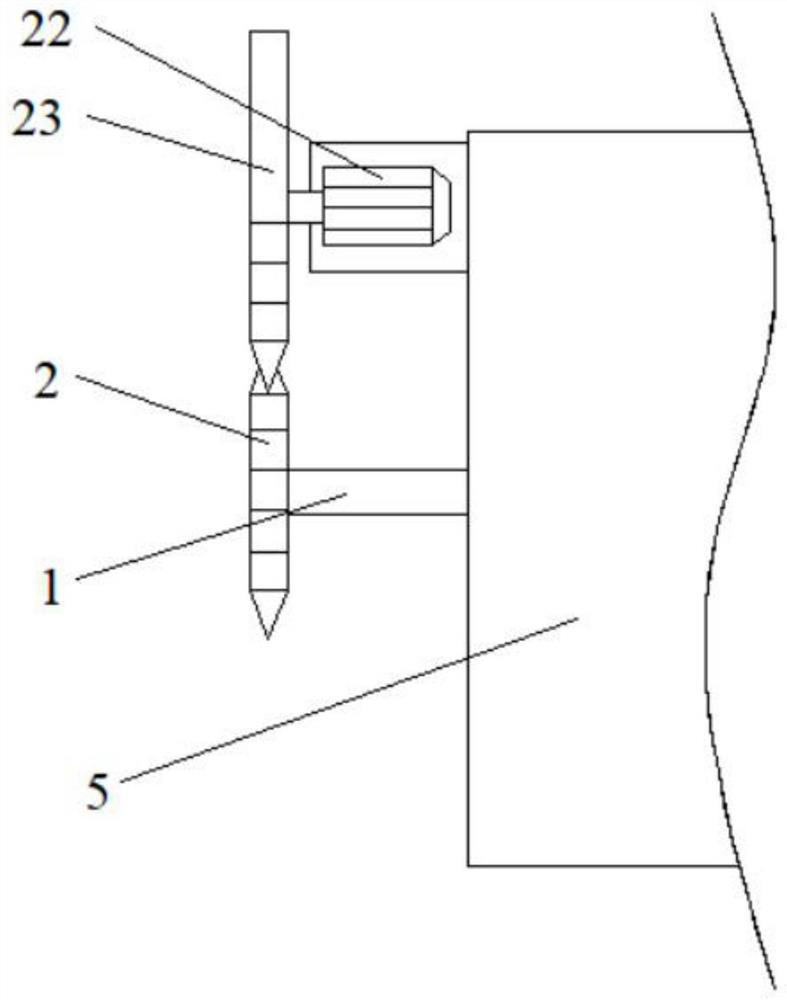

The invention relates to rolling cutting equipment, in particular to wood stick sharpening equipment for garden fence construction. The purpose of the invention is how to design wood stick sharpeningequipment for garden fence construction, which is capable of improving the wood stick cutting efficiency, easy to operate and uniform in cutting shape. The wood stick sharpening equipment for garden fence construction comprises a base, a horizontal screw, a roller, a disc, a material pushing spring, a push rod, a support table and the like; the top of the base is horizontally provided with the horizontal screw, and the right side of the top of the base is fixedly connected with the roller; the roller is provided with a cutter head and is in a conical shape, and the tail end of the roller is connected with the disc; the middle of the disc is slidably provided with the push rod, and the material pushing spring is connected between the tail end of the push rod and the disc and is arranged onthe push rod in a sleeving mode. Through cooperation of a material pushing assembly and the roller, a wood stick can be subjected to quick rolling cutting, and moreover, the wood stick subjected to rolling cutting can be ejected out and is convenient to take out.

Owner:长春城投城建(集团)有限公司

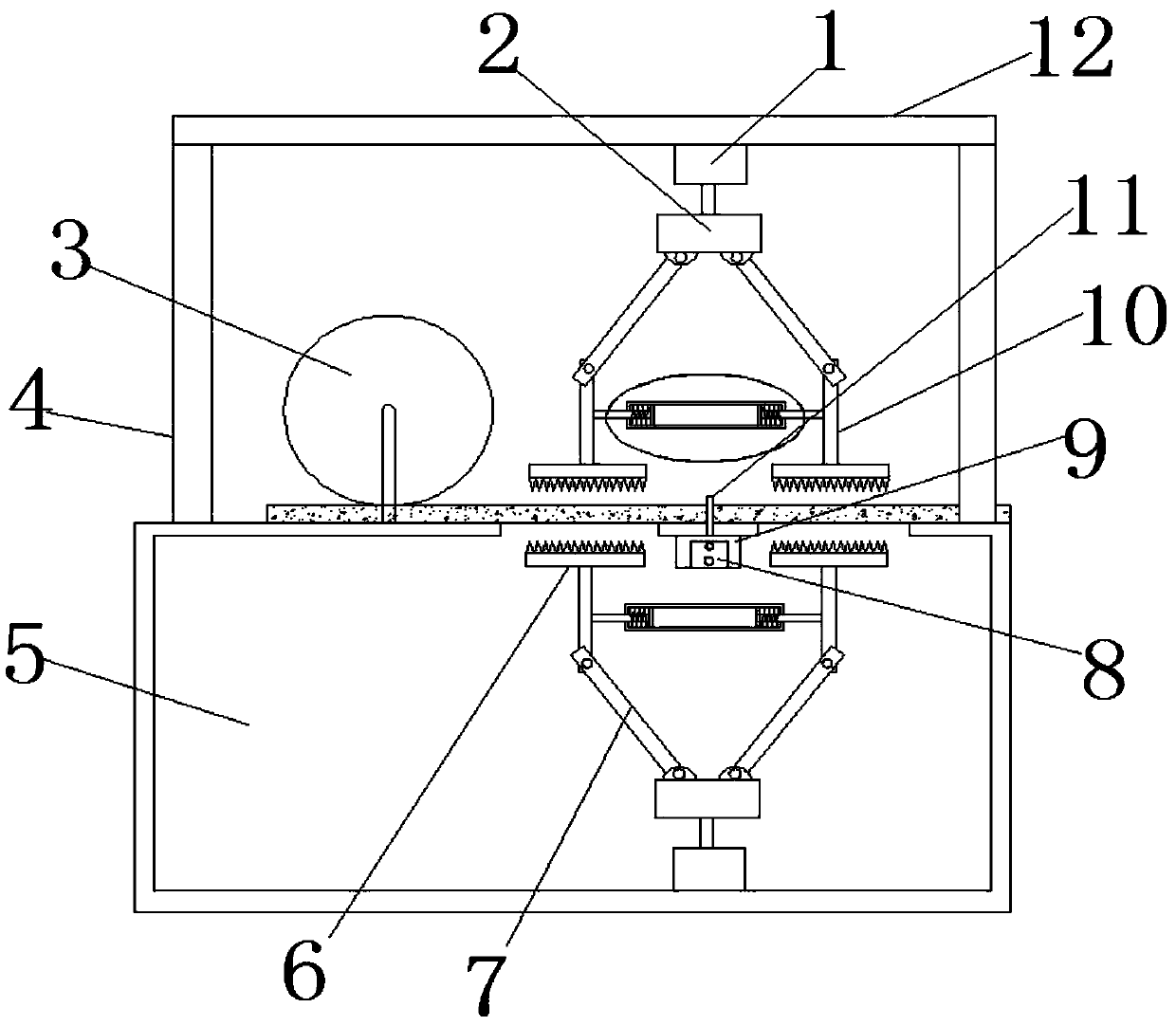

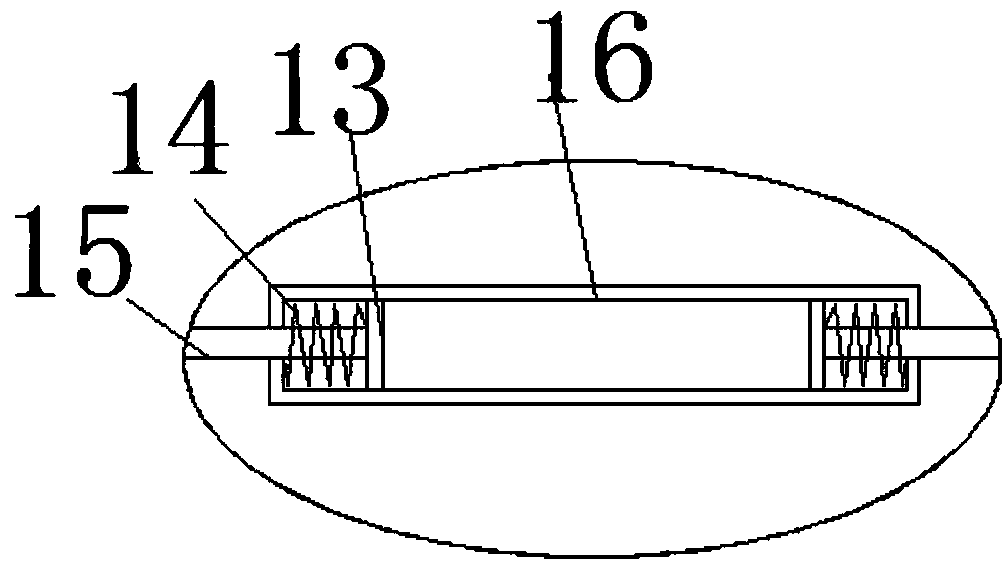

Cutting device for regenerated cotton production

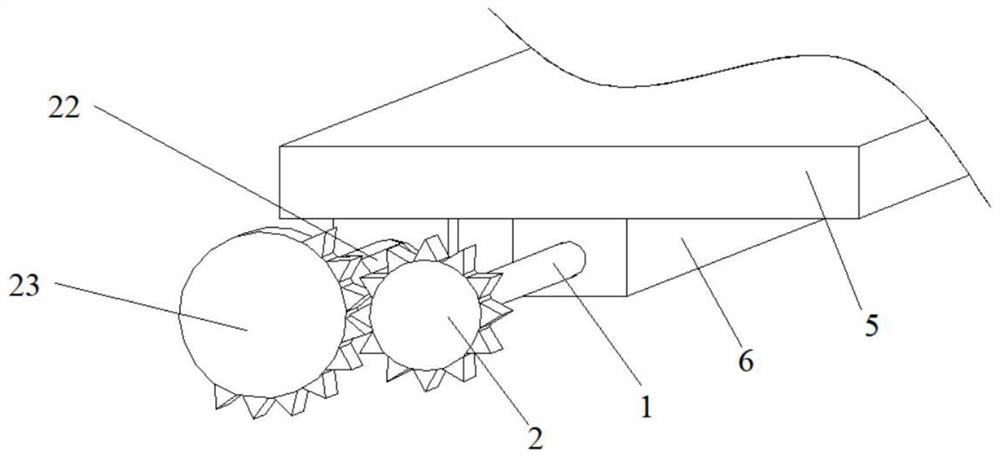

InactiveCN107687084AAchieve mechanical cuttingFast cutting speedSevering textilesMetal working apparatusArchitectural engineeringSerration

The invention discloses a cutting device for regenerated cotton production, which includes a workbench, a pressure roller and a top plate. A pressure roller is installed on the top side of the workbench, and regenerated cotton material is arranged between the workbench and the pressure roller. The top of the workbench is welded with four brackets distributed in an array, the top of the bracket is welded with a top plate, the bottom side wall of the top plate and the bottom side wall inside the workbench are symmetrically fixed with the first push rod motor by screws, and the first push rod motor The output shafts are fixedly connected with mounting blocks, and the bottom ends of the mounting blocks are symmetrically hinged with two first connecting rods, and the two first connecting rods are hinged with vertically symmetrical second connecting rods, and one end of the second connecting rods Both are fixed with symmetrical sawtooth fixing plates, and four pairs of symmetrical sawtooth fixing plates are respectively located above and below the recycled cotton material, and a third connecting rod is connected to one side wall of the second connecting rod. The device has the advantages of simple structure, convenient operation, no need for manual cutting, high cutting speed, improved work efficiency, and saves time and effort.

Owner:阳新俊华再生棉科技有限公司

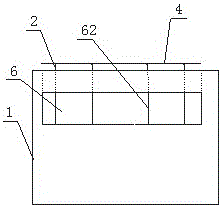

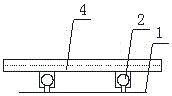

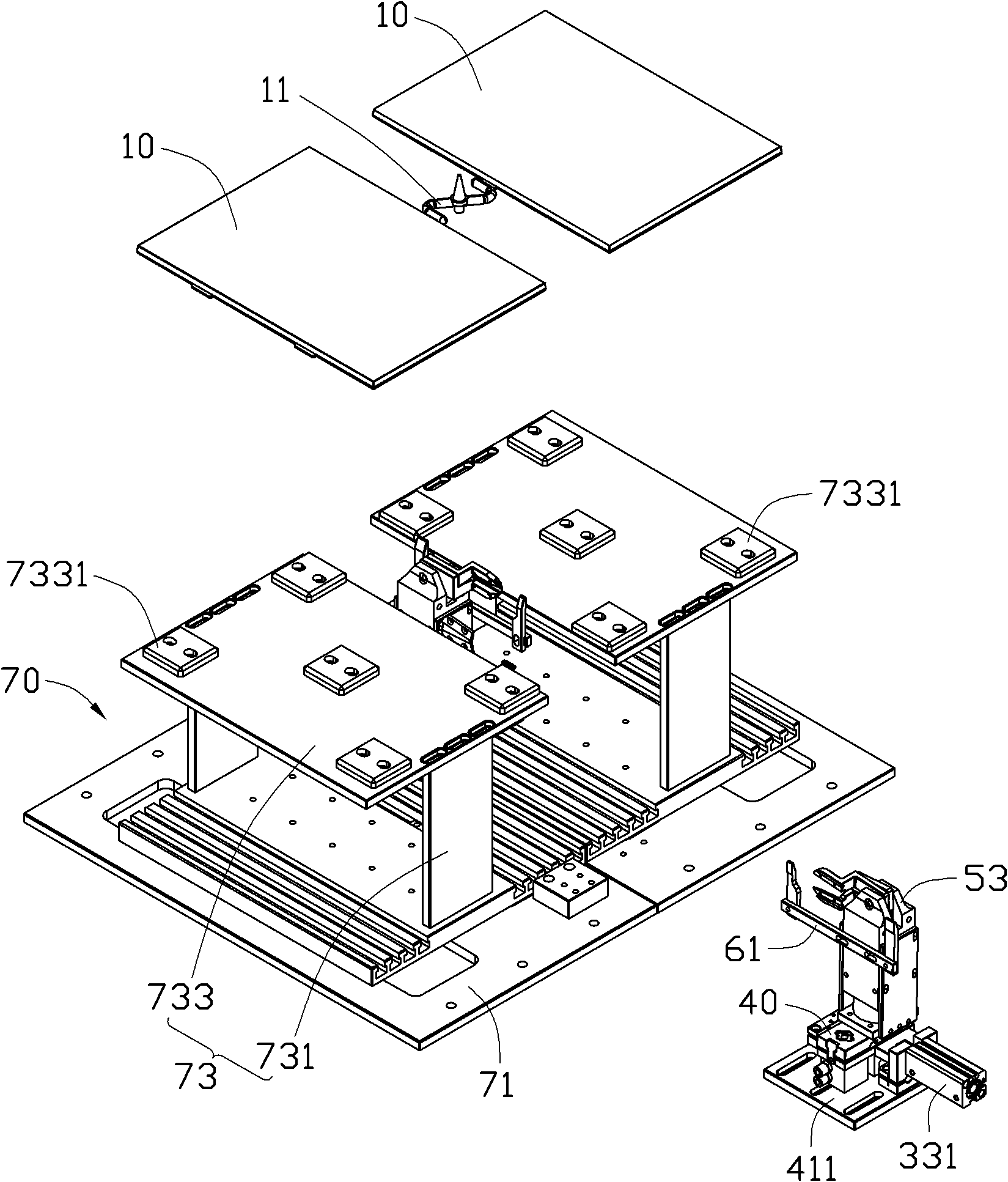

Height adjustable PCB clamping device

InactiveCN106304653AEasy to connect PCB board collecting device or conveying deviceIncrease productivityPrinted circuit manufactureMagnetEngineering

The invention discloses a height adjustable PCB board clamping device, which comprises a work table, guide rails, a clamping plate and a plate exiting passage. Each guide rail is fixedly arranged on the worktable, with one end provided with a mounting machine and other end the plate exiting passage. The at least two groups of guide rails are parallel from each other, and are connected with the clamping plate in a sliding manner. The clamping plate comprises a first clamping plate and a second clamping plate which are mutually parallel. The first clamping plate and the second clamping plate are connected through a spring. The spring is in parallel with the guide rails. The worktable is further fixedly provided with a magnet. The magnet is located at one end of the plate exiting passage near the mounting machine. The lower surface of the plate exiting passage is provided with at least two position limiting strips. The position limiting strips are arranged right under the tracks of the guide rails. The bottom of the worktable is provided with at least three broken line shaped lifting supports, and the broken points of the lifting supports are mutually fixed through screws. According to the invention, the clamping device can be used to PCBs in varied sizes. With simple operations, the height can be effectively adjusted so as to meet the requirements of large, middle and small sized enterprises.

Owner:成都鼎翔通信技术有限公司

High-efficient automatic film blowing device capable of preventing electrostatic interference

ActiveCN111497204AScientific and reasonable structureEasy to useDispersed particle filtrationMetal working apparatusActivated carbonDust control

The invention discloses a high-efficient automatic film blowing device capable of preventing electrostatic interference. The high-efficient automatic film blowing device capable of preventing the electrostatic interference is characterized in that a dust removing box body is fixedly connected to one end of an axial flow fan, a dust filtering plate is fixedly mounted at the top of the dust removingbox body, an activated carbon adsorption plate is fixedly mounted in the middle of the dust removing box body, a first connecting pipe is fixedly connected to one end of the bottom of the dust removing box body, a first adsorption box body is fixedly mounted at one end of the first connecting pipe, a second connecting pipe is fixedly connected to the top end of the first adsorption box body, anda second adsorption box body is fixedly mounted at one end of the second connecting pipe. The high-efficient automatic film blowing device is scientific and reasonable in structure and safe and convenient in use, through the cooperative use of the dust filtering plate and the activated carbon adsorption plate, waste gas generated by plastic melting is conveniently filtered, dust and substances with peculiar smells contained in the waste gas are removed, the situation that the dust and the substances with the peculiar smells are directly discharged into air, so that the atmosphere is polluted is avoided, and through the cooperative use of the first adsorption box body and the second adsorption box body, harmful gas dissolved in water and limewater in the waste gas is absorbed.

Owner:CHAOHU JINBANG PLASTIC PACKAGING

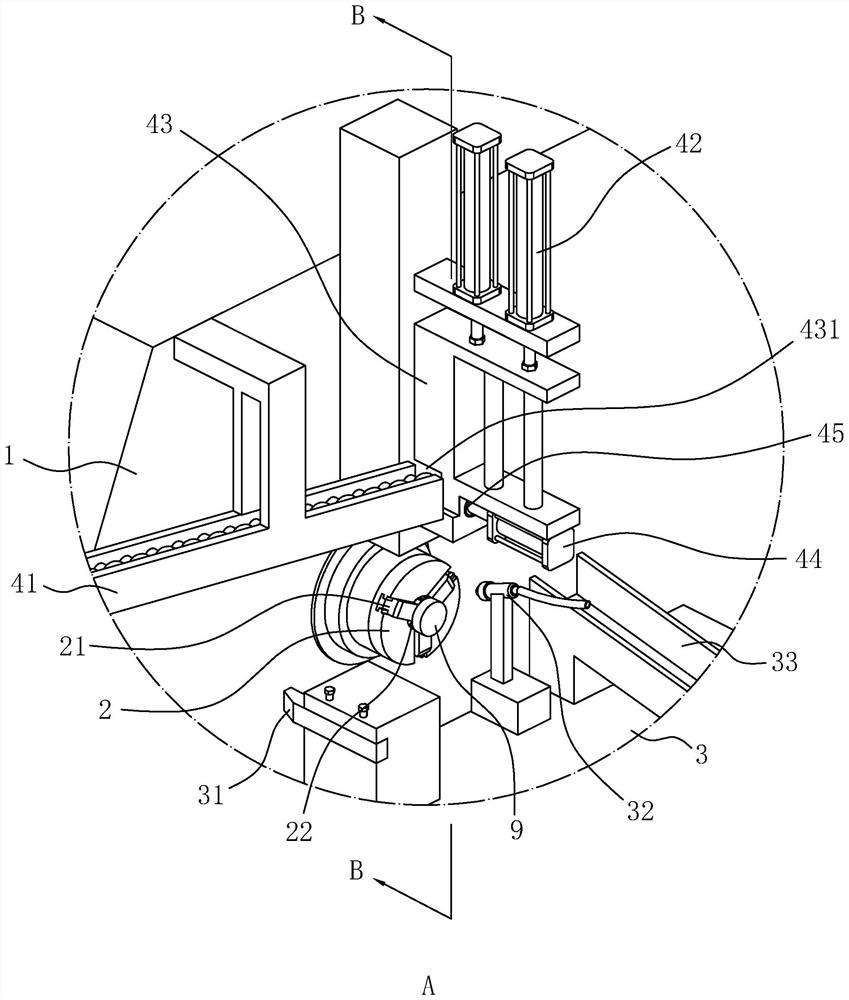

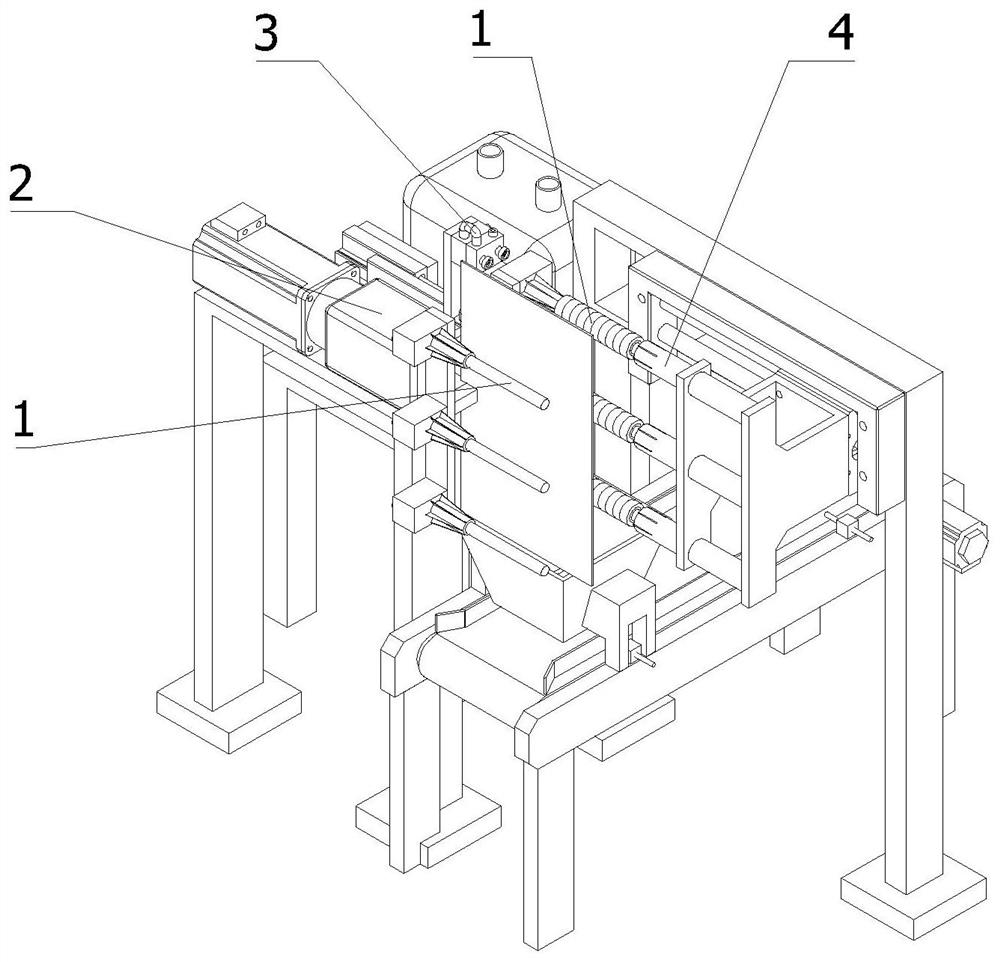

Automatic separator for porous bobbin and yarns

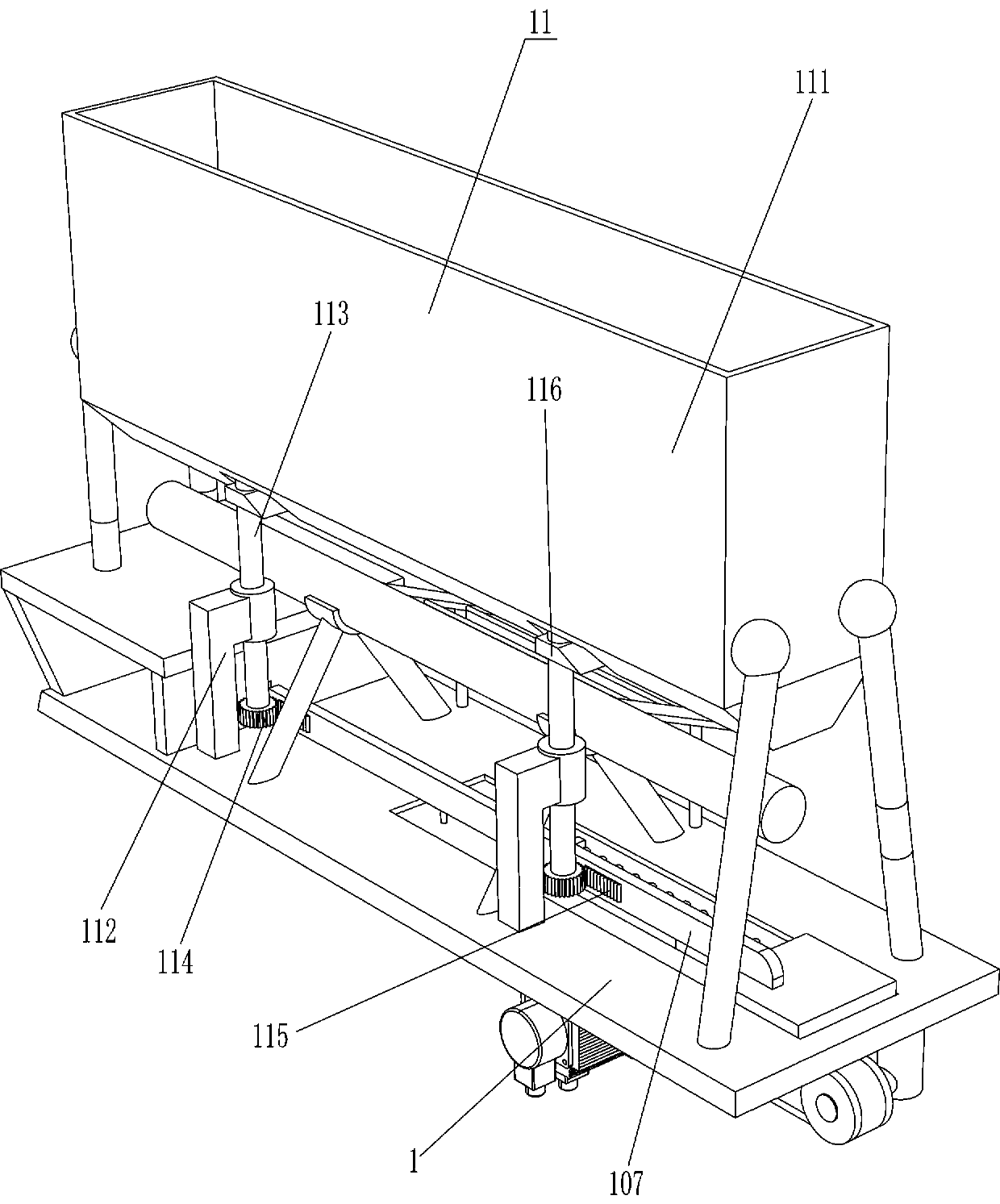

ActiveCN105568450AReduce labor intensityImprove the efficiency of the cutting processTextiles and paperYarnBobbin

The invention relates to an automatic separator for a porous bobbin and yarns. The automatic separator comprises a rack, a feeding mechanism, a charging mechanism, a rotating mechanism, a cutting mechanism and a yarn attracting mechanism, wherein the rack is provided with a workbench which is provided with a charging position, a cutting position and a bobbin detaching position, and the feeding mechanism, the charging mechanism, the rotating mechanism, the cutting mechanism and the yarn attracting mechanism are arranged on the workbench. The automatic separator can be used for cutting a redidual bobbin automatically, so that the efficiency of a cutting process is enhanced greatly, the labor intensity of operators is lowered, mannual cutting is omitted, and the safety factor is improved greatly.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

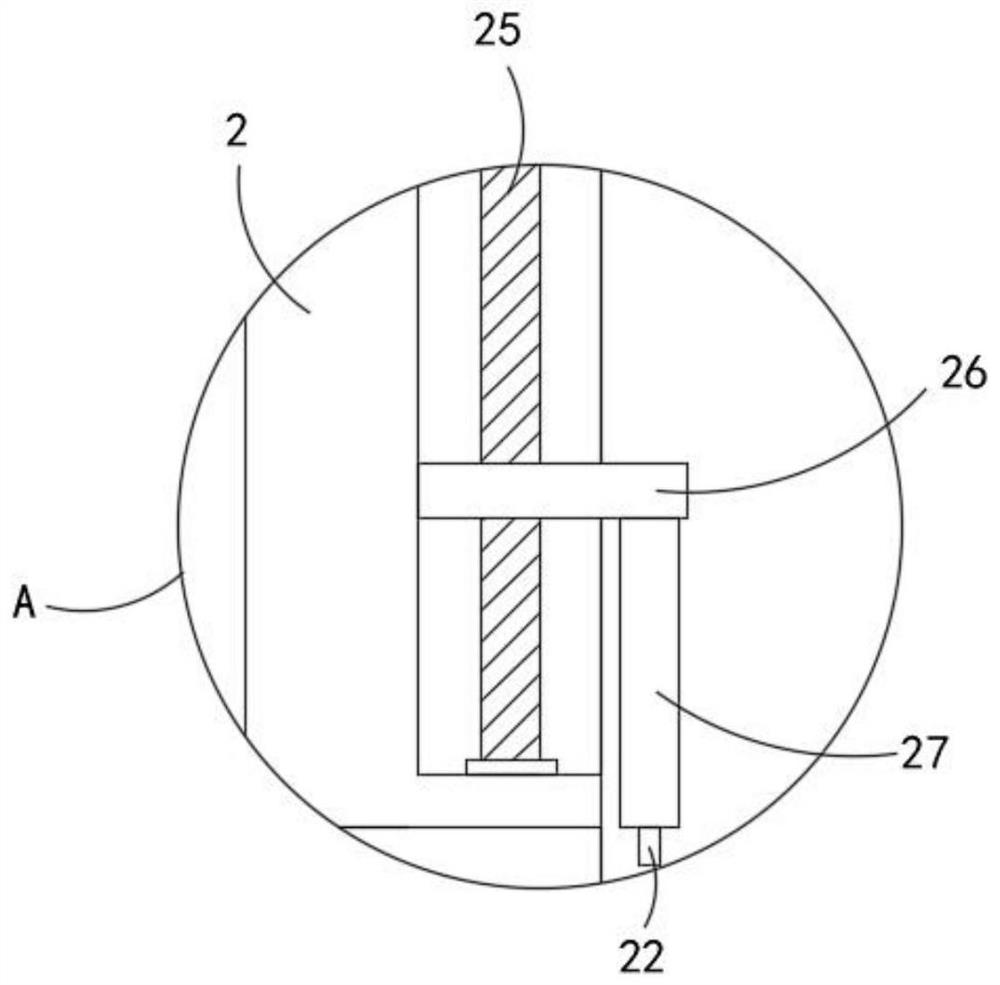

Intelligent conveying device for food and beverage production

ActiveCN112357866APrevent production process impactImprove work efficiencyConveyorsLiquid bottlingControl engineeringBottle

The invention relates to the technical field of food and beverage production, and discloses an intelligent conveying device for food and beverage production. The intelligent conveying device comprisesa mounting block. According to the intelligent conveying device for food and beverage production, a beverage bottle is placed between left and right clamping plates, then a push rod is pushed to drive a moving block to move along a driving frame, the moving block drives an inserting rod to move through a mounting spring, and the inserting rod drives a first push block to move, so that the first push block drives a second push block to move left and right along a mounting frame; the second push block drives a limiting plate to move, and the limiting plate drives two connecting rods to move, sothat the two connecting rods drive the clamping plates to move; beverage bottles of different sizes are clamped by adjusting the distance between the two clamping plates; meanwhile, a limiting rod moves into a clamping groove under the action of a reset spring to be connected with the clamping groove in a clamped mode, thus, the position of the first push block is fixed, and the influence on theproduction process due to toppling of the first push block is prevented; and the problem that only beverage bottles of one size can be clamped is solved.

Owner:BENGBU KUNPENG FOOD & BEVERAGE

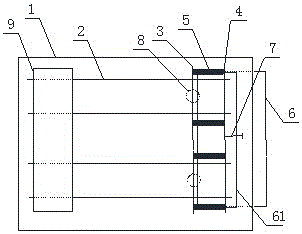

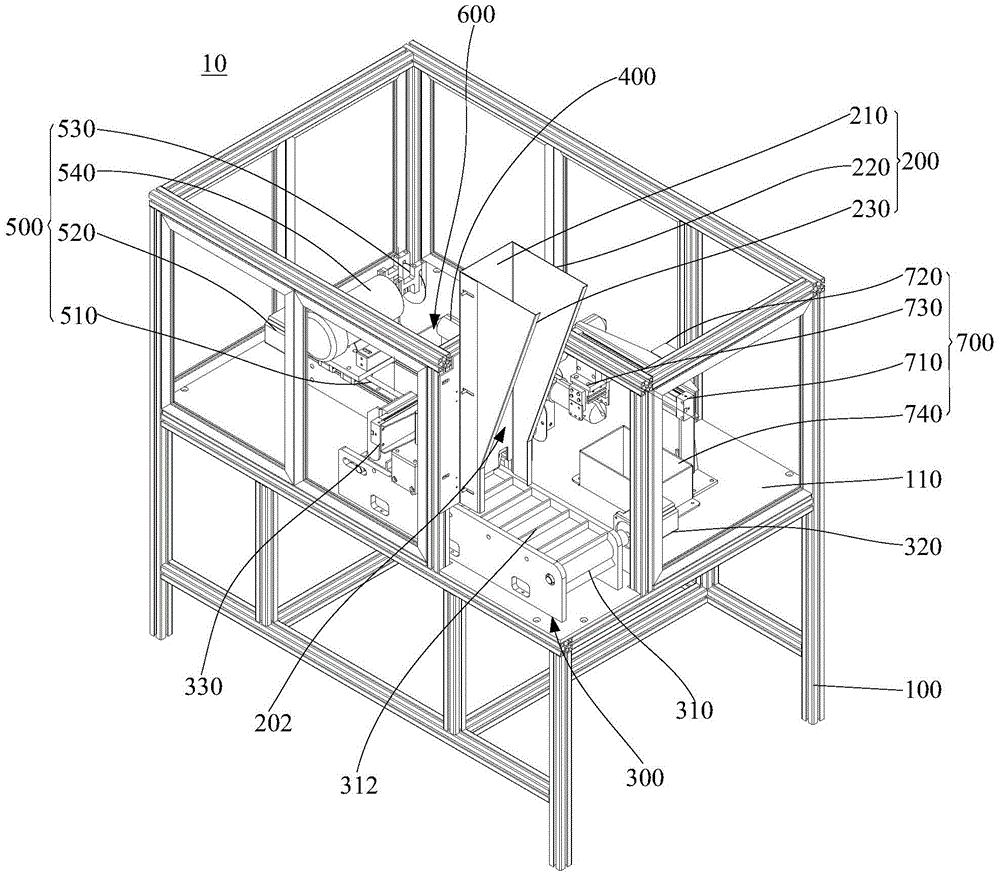

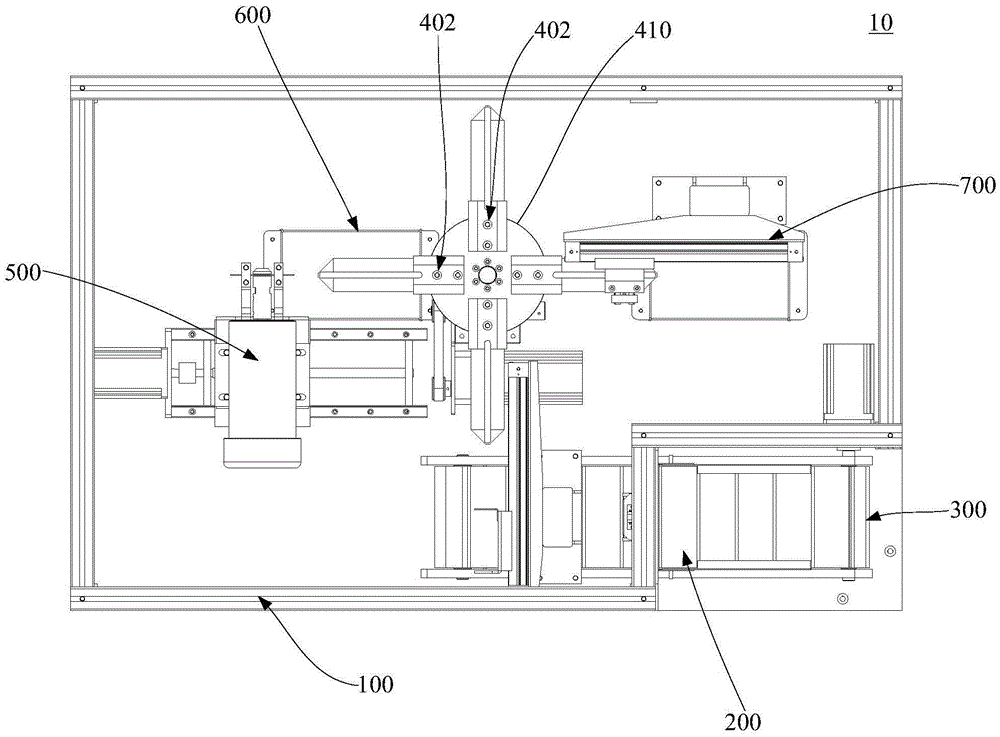

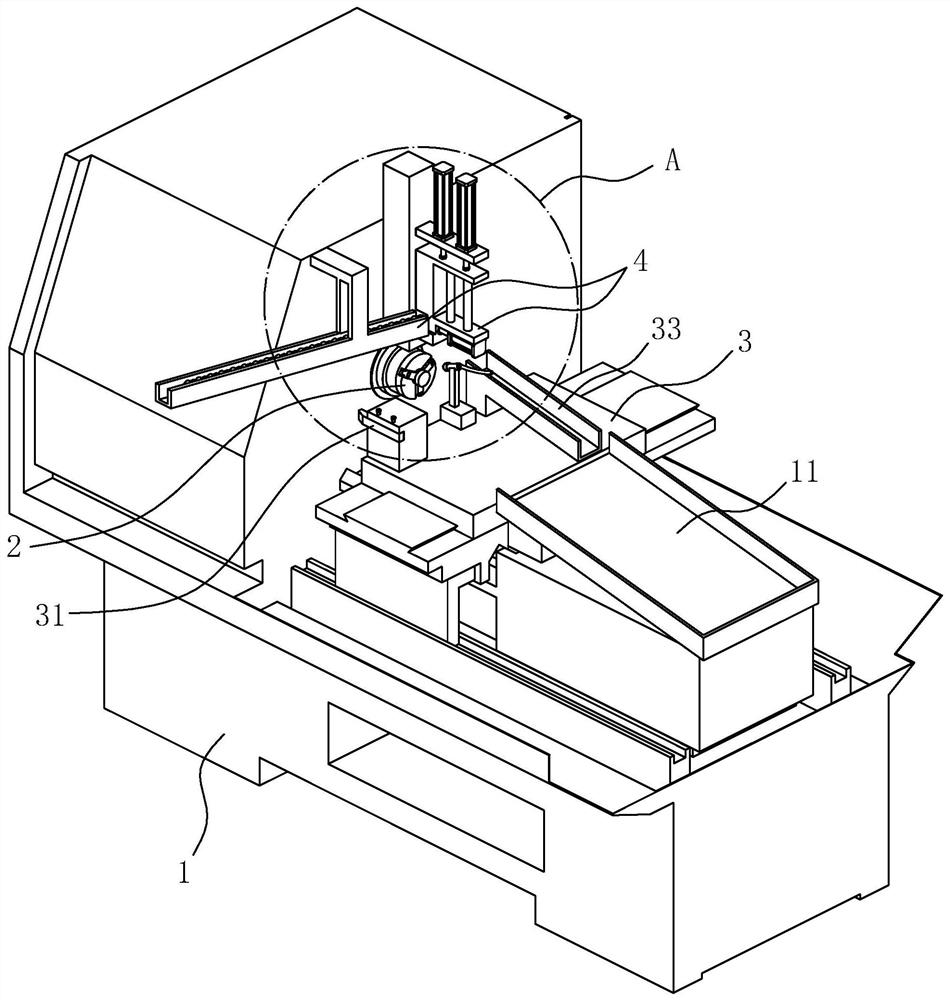

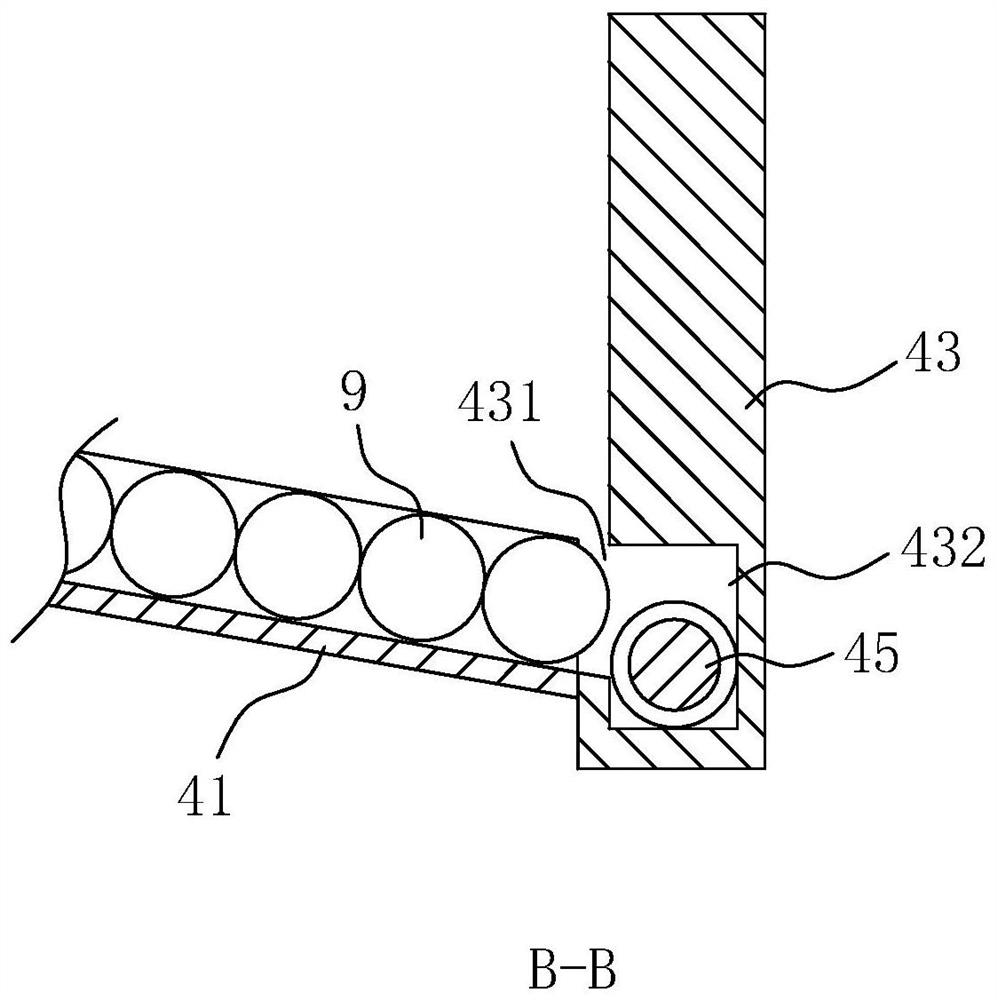

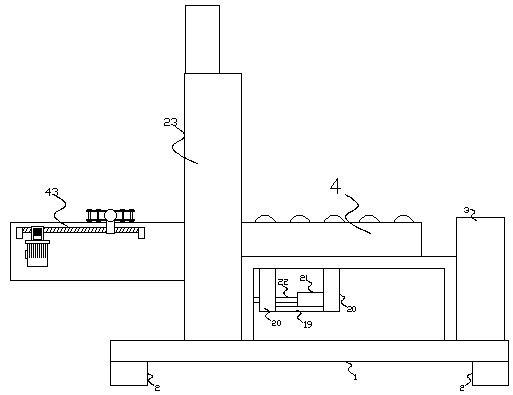

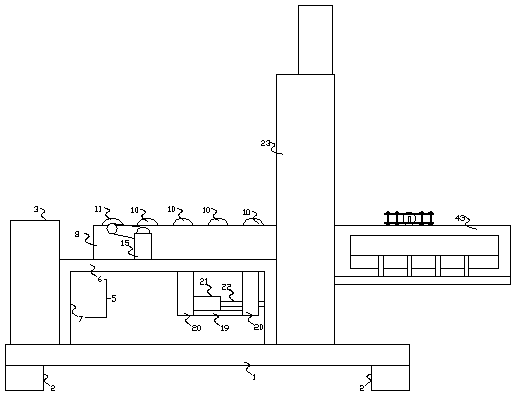

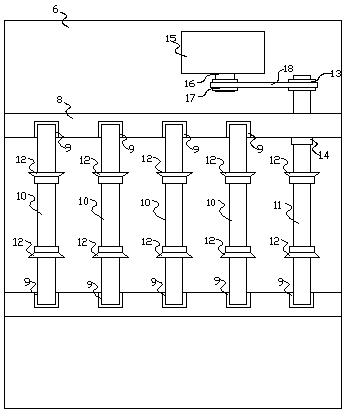

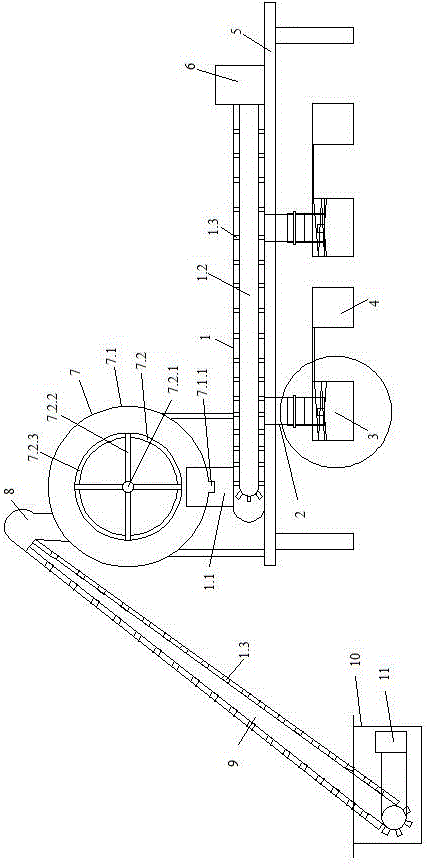

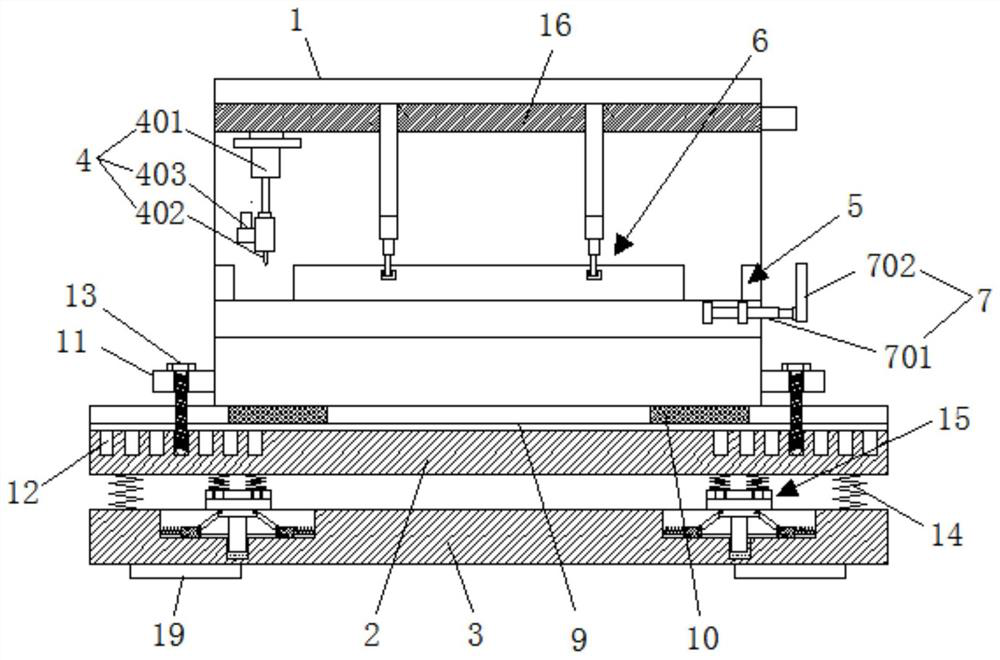

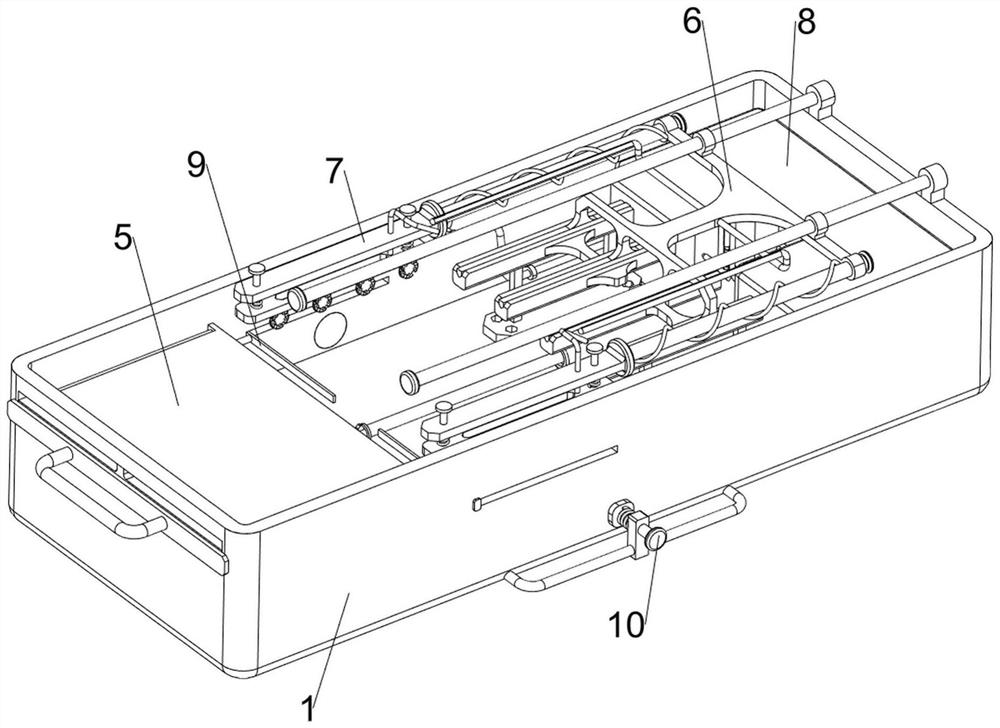

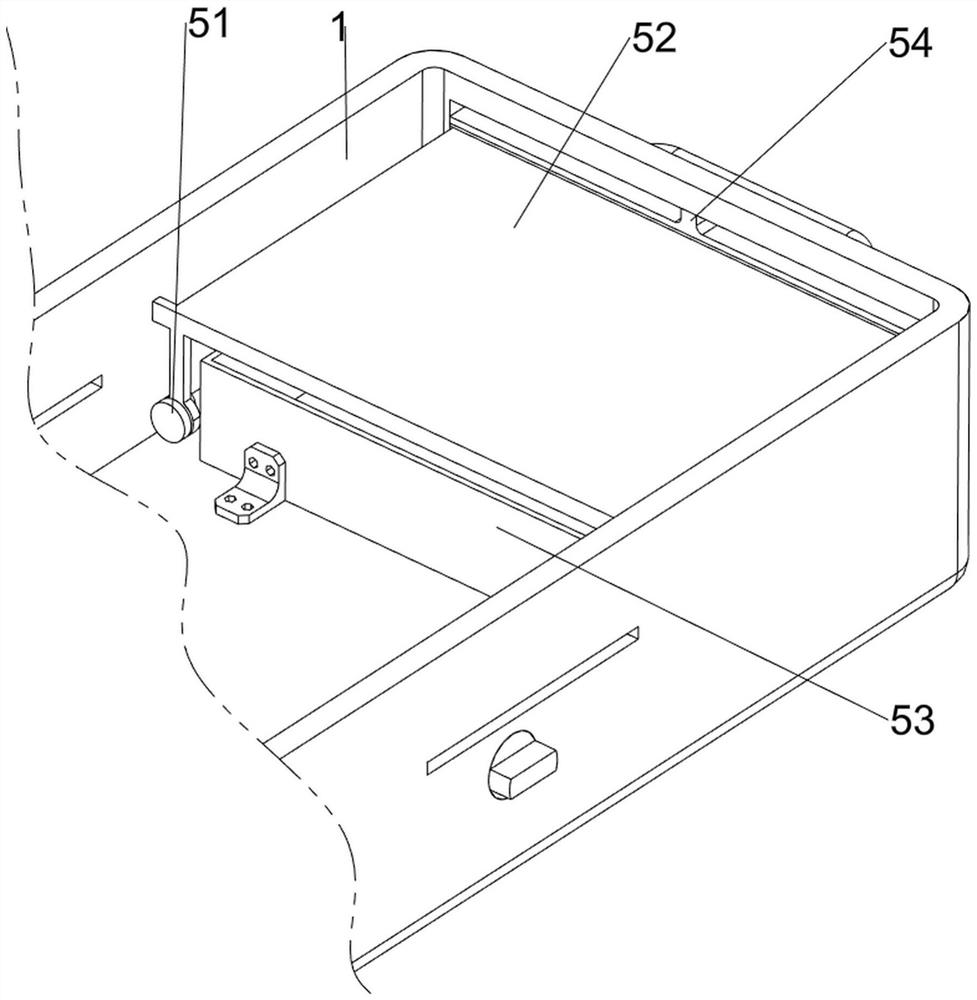

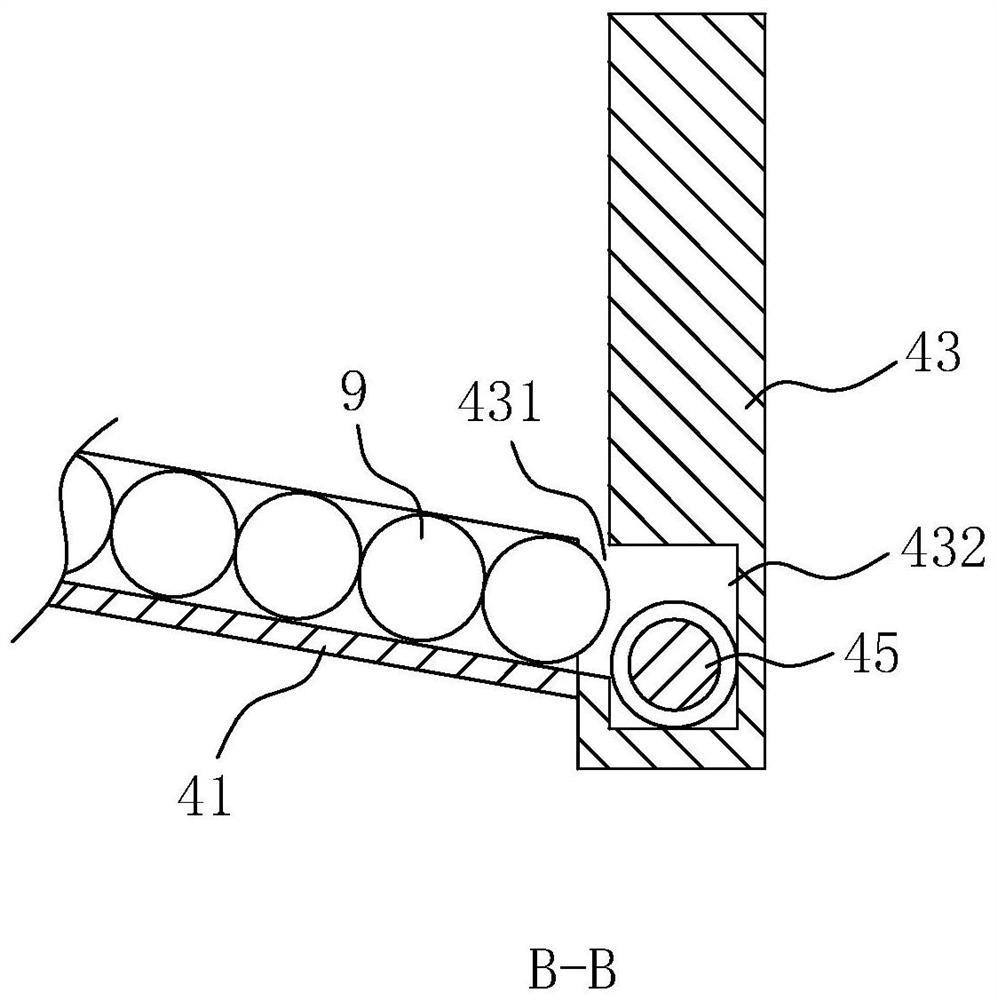

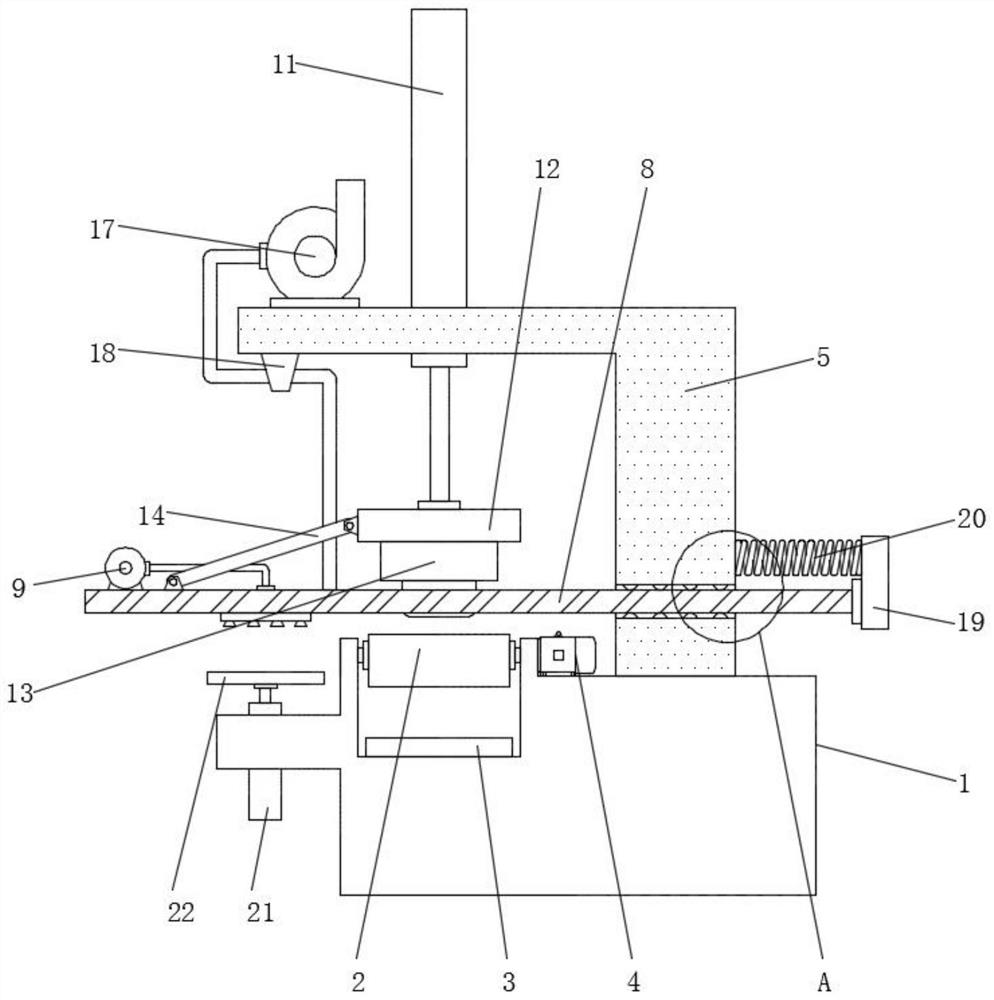

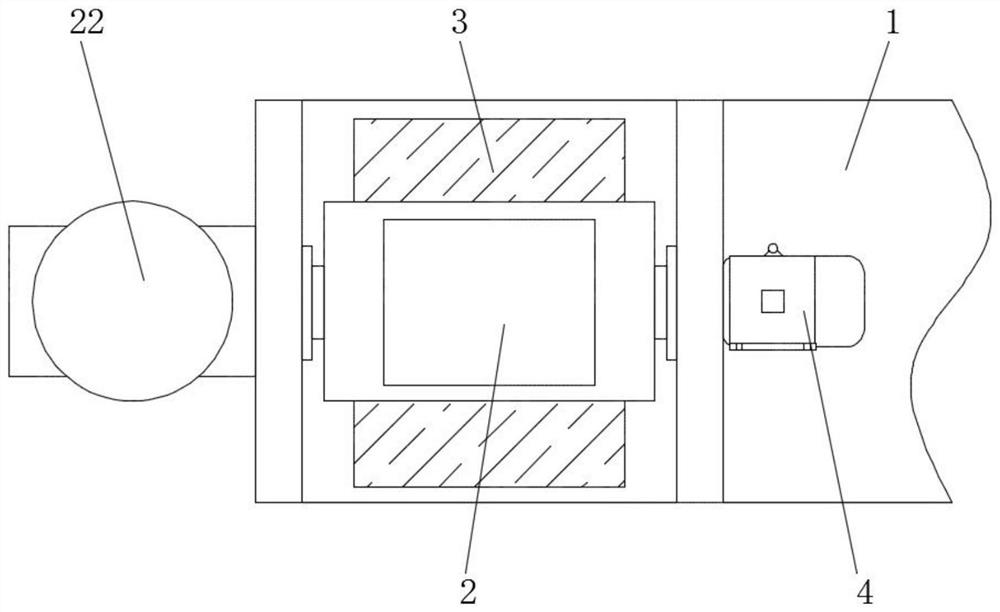

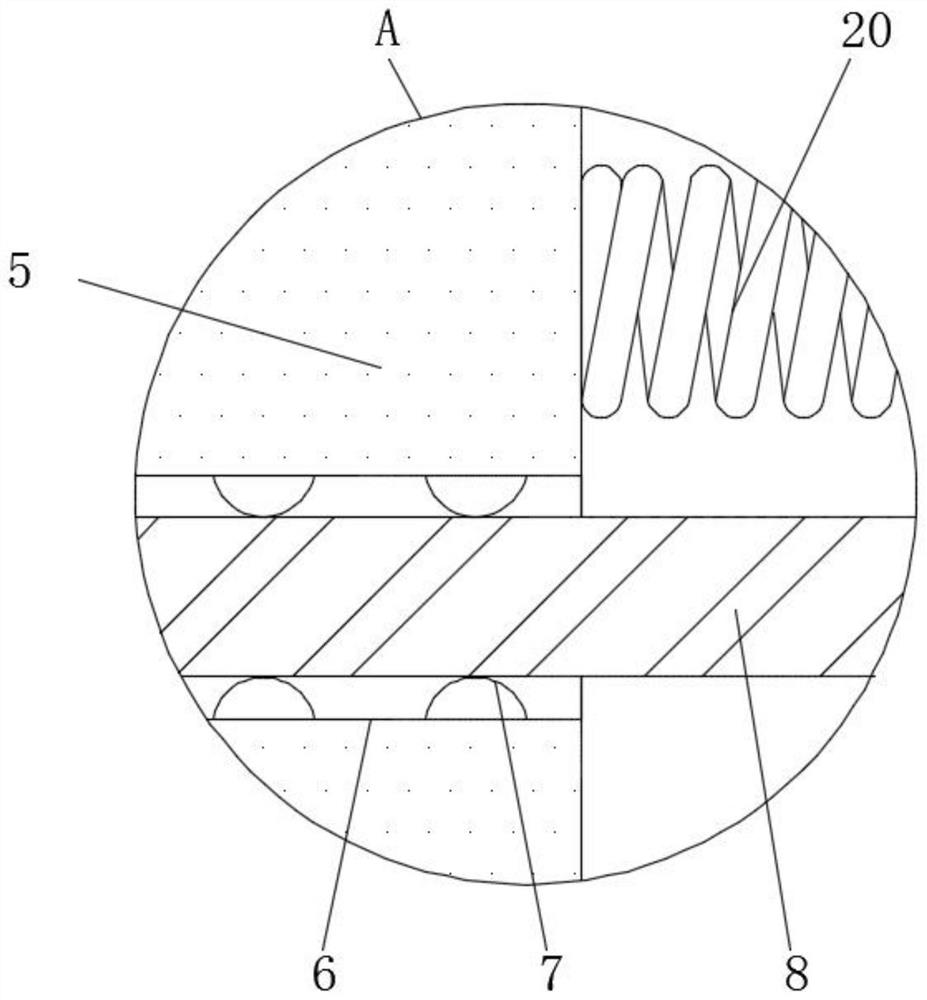

Numerical control machine tool with material guiding track

ActiveCN111890103ANo need for manual cuttingReduce laborMetal working apparatusMaintainance and safety accessoriesNumerical controlMachine

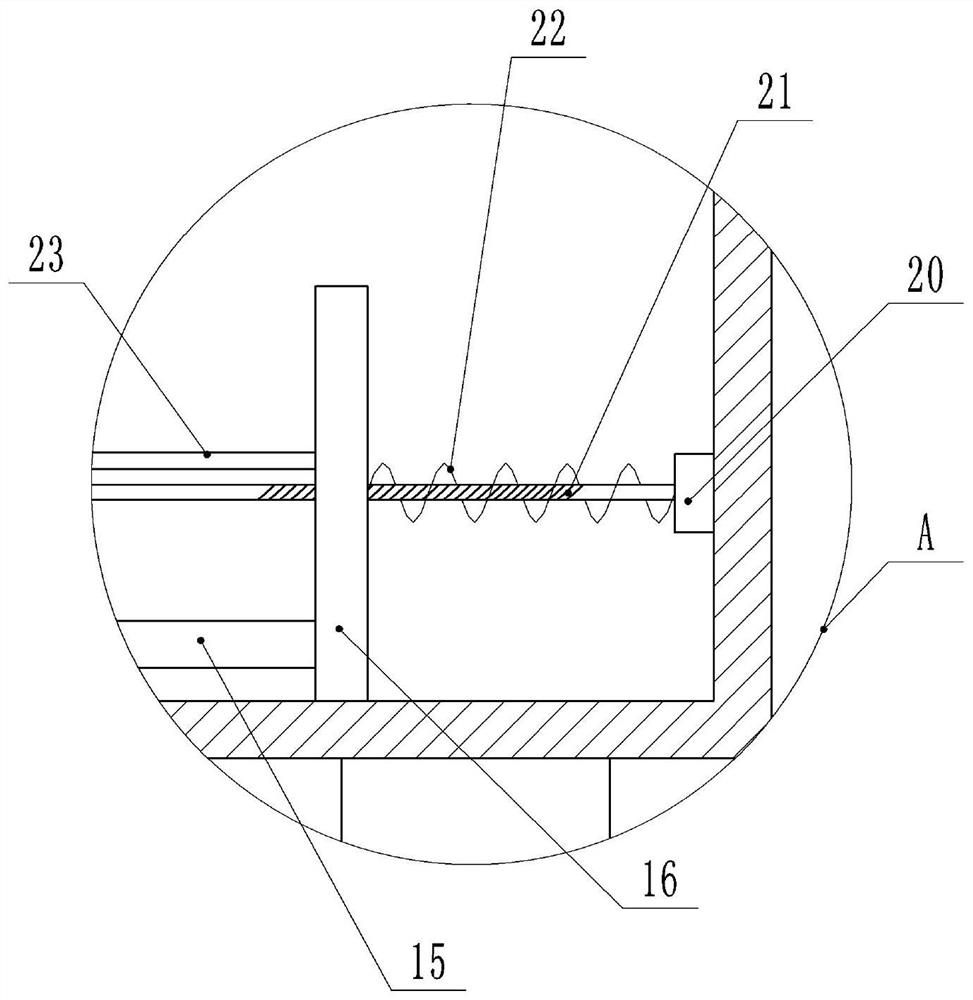

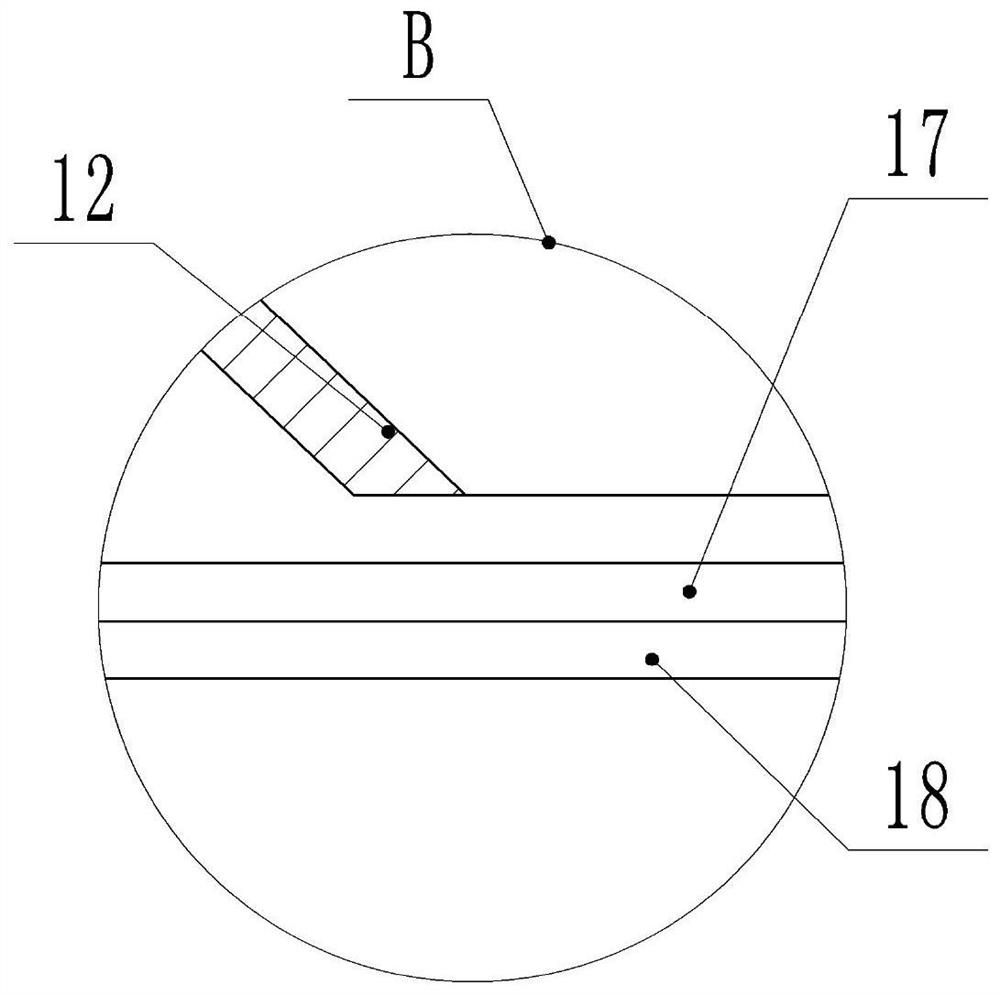

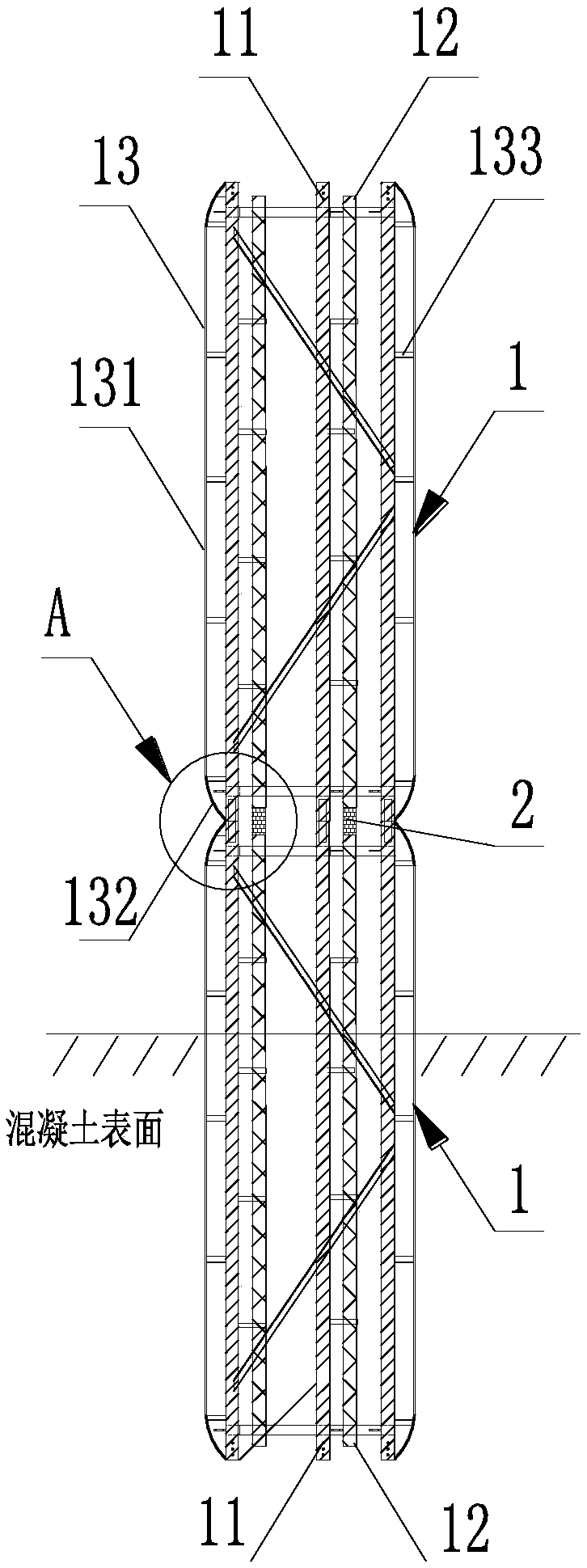

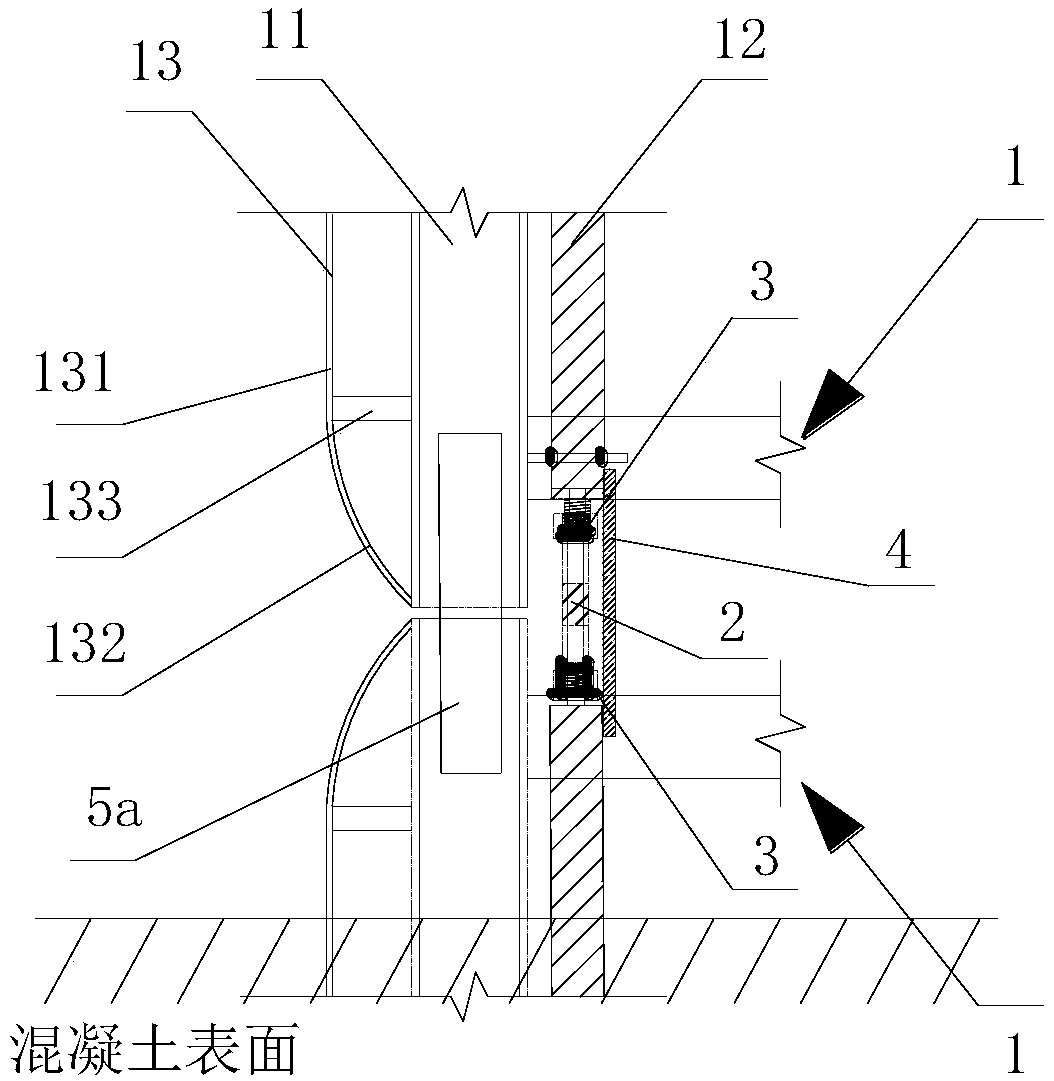

The application relates to a numerical control machine tool with a material guiding track and relates to the field of machine tools. The numerical control machine tool comprises a rack and a chuck forclamping workpieces, wherein the chuck is driven by a driving source to rotate; a carriage is arranged on a rack in sliding manner and is provided with a tool; the chuck is provided with a pluralityof clamping blocks for clamping workpieces along the circumferential direction; the moving direction of the clamping blocks is long the radial direction of the chuck; the center of the chuck is provided with a mounting hole; elastic elements are arranged in the mounting hole; the elasticity direction of the elastic elements is along the axial direction of the chuck; the elastic elements can ejectthe workpieces on the chuck; the carriage is also provided with the material guiding track; and the material guiding track is enabled to directly opposite to the chuck by sliding through the carriage.The numerical control machine tool can automatically eject the workpieces out of the chuck; the workpieces are guided by the material guiding track to enter a receiving tray for storing without manual discharging, so that labor intensity is reduced; and a feeding mechanism is arranged for automatically feeding the workpieces.

Owner:台州一鼎数控机床有限公司

Cable cutting device for electric power construction

ActiveCN112332321AEasy to cutEasy to peelApparatus for removing/armouring cablesScrew threadElectric cables

The invention discloses a cable cutting device for electric power construction. The cable cutting device comprises a workbench, a top frame is installed at the top of the workbench, and a cutting mechanism is installed on the top frame; a supporting plate is arranged below the cutting mechanism, one end of the supporting plate is hinged to one side of the inner wall of the top frame, and a pullingrod is hinged to the other end of the supporting plate. Two lead screws are mounted at the two sides of the outer wall of the top frame, the lead screws are sleeved with mounting blocks in a threadedmanner, and peeling knife handles are assembled on the side walls of the mounting blocks. Peeling knives are connected to one ends of the peeling knife handles, a mounting cavity is formed in the workbench, a collecting cover is mounted on the inner wall of the mounting cavity, a mounting shaft is arranged at the top of the collecting cover, and a plurality of crushing cutters are equidistantly connected to the outer wall of the mounting shaft in the circumferential direction. According to the cable cutting device, a cable can be cut, the outer surface of the cable can be cut and peeled, theproblem that a traditional cutting device cannot peel the cable is solved, chippings and peeled outer skin can be smashed, the size is reduced, and collection is convenient.

Owner:山东坤厚电力科技有限公司

Special shearing machine for radiator aluminum profile production

PendingCN108856836AReduce manufacturing costNo need for manual cuttingMetal-working feeding devicesShearing machinesMechanical engineeringHeat spreader

The invention discloses a special shearing machine for radiator aluminum profile production. The machine comprises a base, a pushing tool, a shearing tool, a positioning tool and a PLC; a full-automatic PLC is adopted; the PLC is programmed; and the PLC sends signals to each element according to programmed procedures without needing manual cutting, so that the cutting accuracy is high, the efficiency is high, the use effect is excellent, and the enterprise production cost is greatly reduced.

Owner:江苏英杰铝业有限公司

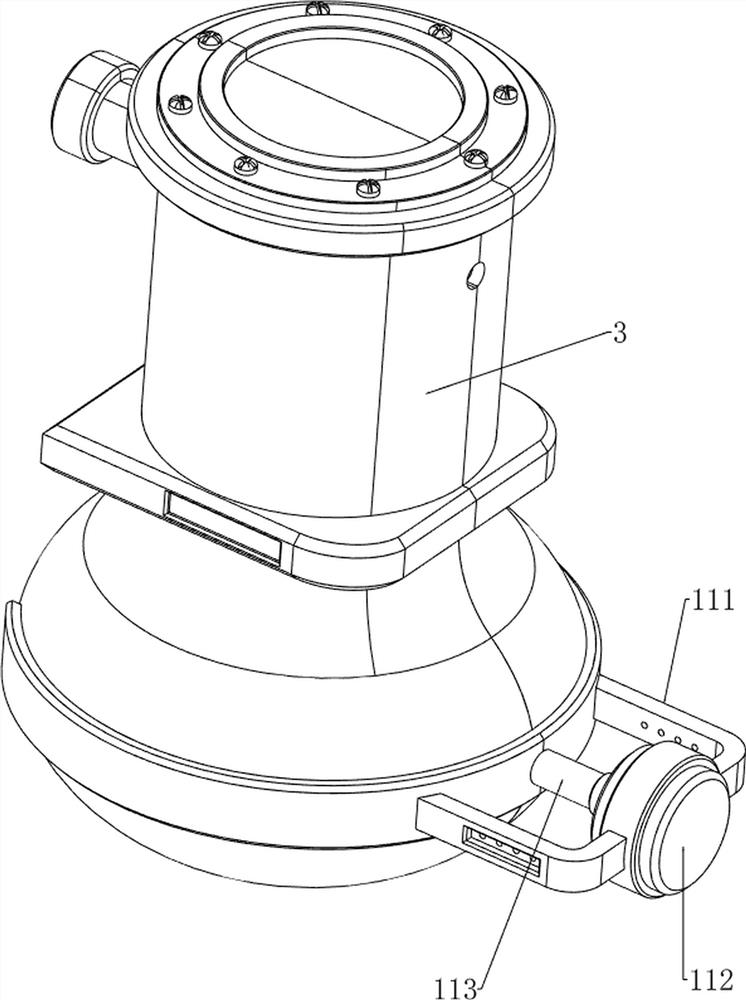

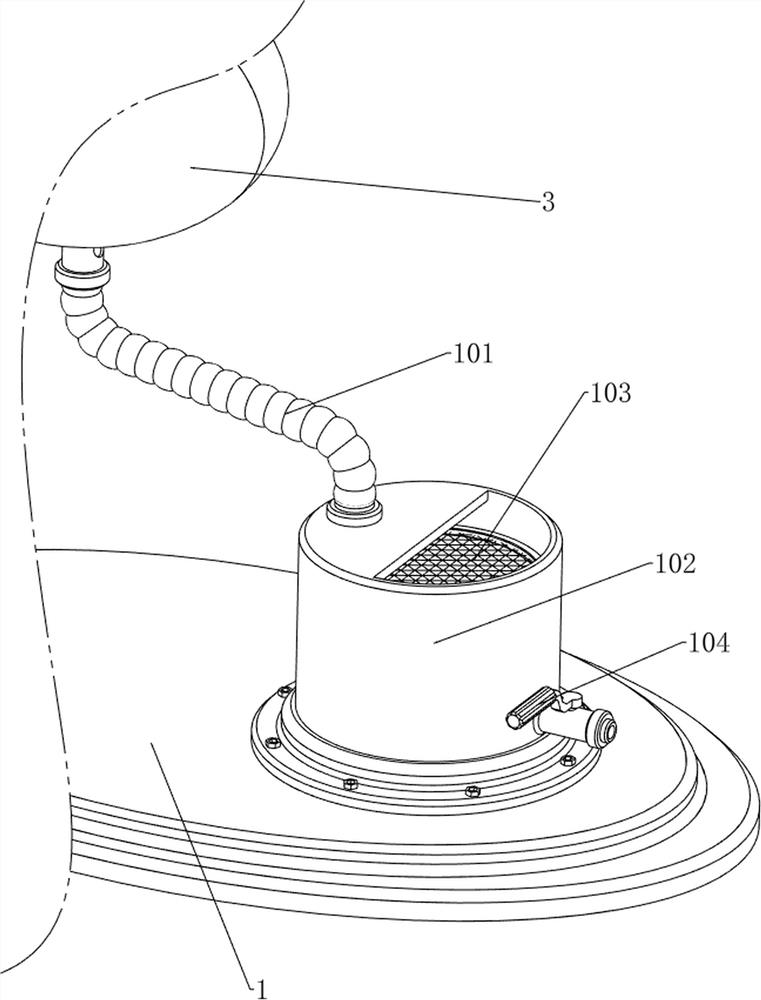

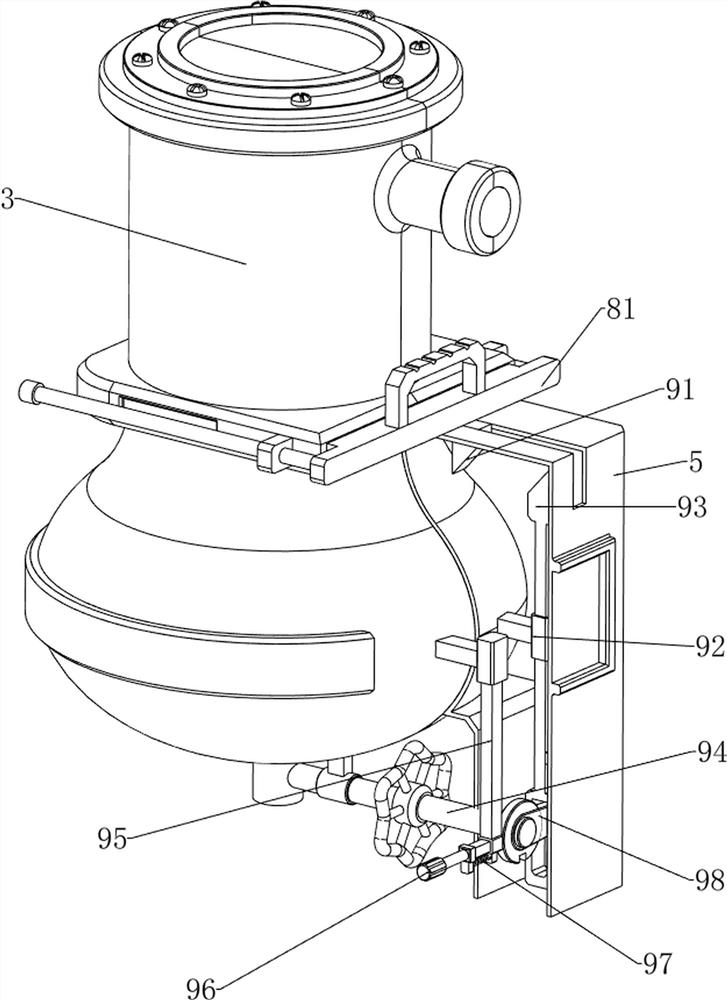

Extraction device for rare earth hydrometallurgy

InactiveCN113637845ARealize the blanking effectExtract pureRotary stirring mixersMixer accessoriesHydrometallurgyVALVE PORT

The invention relates to a separation device, in particular to an extraction device for rare earth hydrometallurgy. The extraction device for rare earth hydrometallurgy, provided by the invention, is relatively uniform in mixing, high in mixing efficiency and simple to operate. The extraction device for rare earth hydrometallurgy comprises a bottom plate and a first support, a first storage box, a feeding frame, a mounting plate, a second support and a first valve; the first support is arranged on the bottom plate; the first storage box is mounted at the top of the first support; the feeding frame is arranged on the upper side of the first storage box; the mounting plate is arranged on the upper portion of the first support, and the mounting plate is connected with the first storage box; the second support is arranged at the bottom of the first storage box; and the first valve is rotationally arranged on the second support. By arranging a material blocking mechanism, when people pull the material blocking mechanism, rare earth and extracting materials flow downwards into the lower side of the first storage box; the rare earth is separated in the first storage box; and then the discharging effect is achieved.

Owner:王鲜

Automatic discharging device

InactiveCN106827128ANo need for manual cuttingImprove labor efficiencySievingScreeningUpper segmentElectrical and Electronics engineering

The invention belongs to the field of bamboo chip processing device, and provides an automatic discharging device. The automatic discharging device comprises a second conveying device, wherein a discharging pipe is arranged under the second conveying device, bamboo chips are discharged through the discharging pipe, the bottom edge of the discharging pipe is in contact with the object accommodating surface of a quiet vibrating device, a side discharge hole is formed in the bottom edge of the discharging pipe, the width of the side discharge hole is 10 to 15 cm, the height of the side discharge hole is 20 to 30 cm, the vibrating device is a vertical circular vibrating machine, the vibrating device is connected with a bamboo chip perforating device, and the discharging pipe is divided into an upper discharging pipe and a lower discharging pipe; the upper discharging pipe is communicated with the bottom of the second conveying device, and the lower discharging pipe sleeves the outside of the upper discharging pipe. The automatic discharging device has the beneficial effect that manual discharging is not needed, so that the labor efficiency is improved.

Owner:HUNAN CHANGDI LONGYIN BAMBOO IND

Rapid cutting equipment for iron furniture

The invention discloses rapid cutting equipment for iron furniture. The equipment comprises a rack, a bearing seat, a base, a cutting mechanism, a reinforcing steel bar placing assembly, a reinforcing steel bar fastening device, an abutting plate assembly, a first spring, a buffer connecting device, a transverse guide rail and a reinforcing steel bar collecting device. The rack is a transversely-arranged U-shaped machine body internally provided with a U-shaped cavity, and the transverse guide rail is arranged at the top of the U-shaped cavity of the rack; and the cutting mechanism is connected with the transverse guide rail, and the cutting mechanism can move back and forth in the axial direction of the transverse guide rail through operation of the transverse guide rail and reach a designated station. The position of reinforcing steel bar cutting equipment can be adjusted on a construction site according to environmental requirements, the cutting equipment does not need to be moved, the application range is wide, practicability is high, vibration of the cutting equipment is greatly weakened through a multi-element buffering structure, the stability of the cutting equipment during working is guaranteed, the service life of the cutting equipment is prolonged, and manual discharging is not needed.

Owner:新余山海企业服务有限公司

Honeysuckle quantitative analysis device

PendingCN112629970AEasy to operateCleverly structuredPreparing sample for investigationCocoaPhysicsElectric machinery

The invention relates to the field of honeysuckle analysis, in particular to a honeysuckle quantitative analysis device which comprises a grinding box and a shearing box, a fixed grinding disc is fixedly connected into the grinding box, a rotary grinding disc is rotatably connected into the grinding box, and the rotary grinding disc is attached to the fixed grinding disc; a crankshaft is coaxially and fixedly connected to the rotary grinding disc, and a motor used for driving the crankshaft to rotate is arranged on the outer side of the crankshaft; a fixed shear is transversely fixed in the shearing box, a sliding shear is in sliding fit with the fixed shear, the fixed shear and the sliding shear each comprise a sheet-shaped body and shear teeth located at the edge of the body, a connecting rod is rotationally connected to the end of each sliding shear, and the end of each connecting rod is rotationally connected with a connecting rod neck of the crankshaft; and an opening is formed in the top of the grinding box, and the bottom of the shearing box communicates with the opening of the grinding box. According to the scheme, the honeysuckle flower shearing and grinding steps are more automatic.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

Square tube material cutting device for machining

InactiveCN111515448AAvoid dentsAvoid bulgingTube shearing machinesPositioning apparatusEngineeringMachining

The invention belongs to the technical field of machining and particularly provides a square tube material cutting device for machining. The square tube material cutting device for machining aims to solve the problem that in the use process of an existing square tube material cutting device, it is found that the fixing effect on a square tube is poor, and the square tube cutting quality is influenced. According to the scheme, the square tube material cutting device for machining comprises a base. Two supporting plates are fixedly installed on the top of the base, and a supporting platen is fixedly installed between the top ends of the two supporting plates. The top end of the supporting platen is fixedly provided with a shell, and the top of the shell is fixedly provided with a feeding sliding table. Side plates are fixedly installed on both sides of the top of the feeding sliding table. According to the square tube material cutting device for machining, fastening fasteners of an inverted-L-shaped structure are used for effectively clamping and fixing corners on both sides of the rectangular square tube, the rectangular square tube is protected against the recession and bulging phenomena in the cutting process, the rectangular square tube is firmly attached to the upper side of the feeding slide table through the pushing force of springs, and therefore the stability is improvedin the cutting process.

Owner:程宏剑

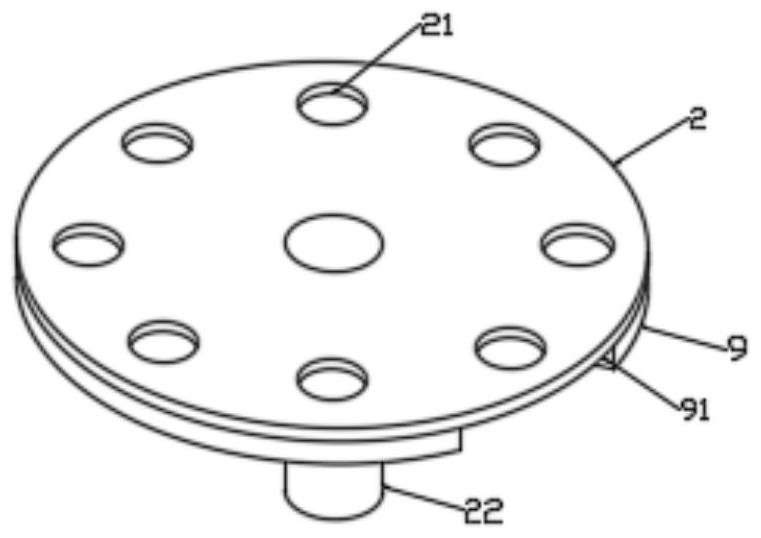

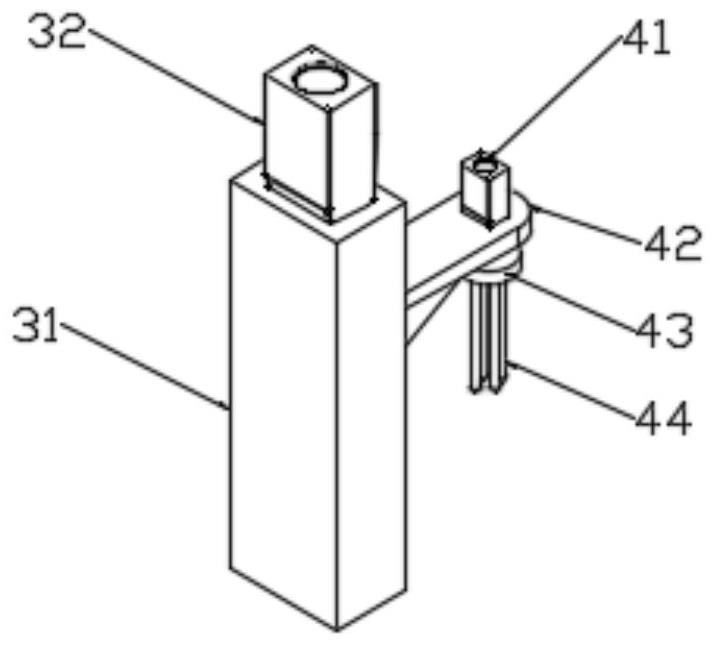

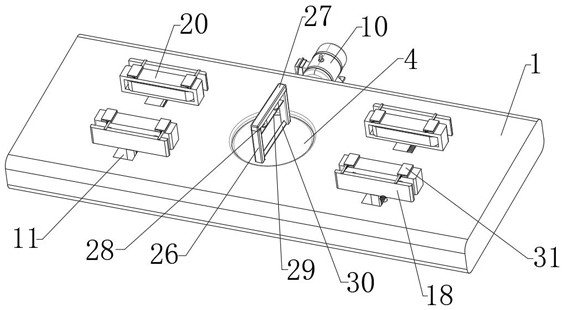

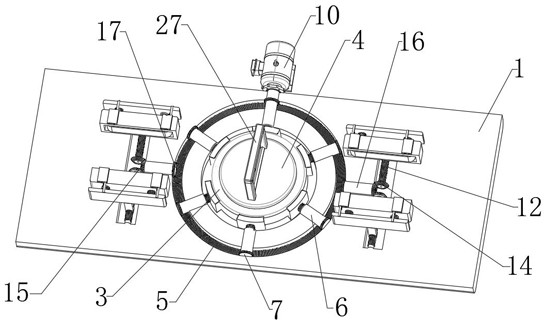

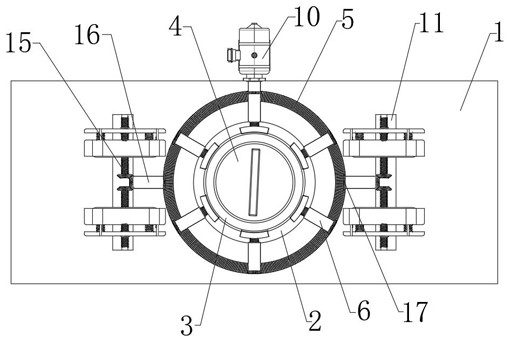

Full-automatic punching device applied to buttons

PendingCN114211566AEasy dischargeImprove processing efficiencyMetal working apparatusEngineeringWorkbench

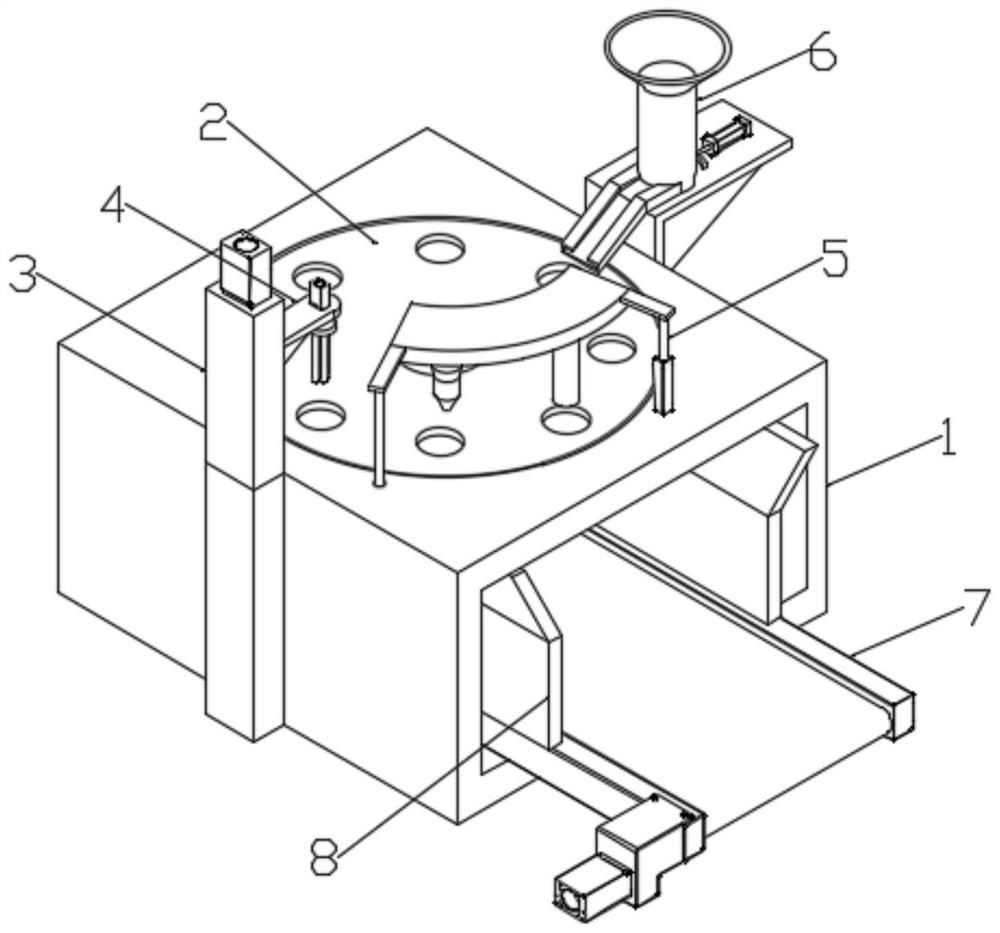

The full-automatic punching device comprises a workbench, a rotating disc used for bearing the buttons is rotationally installed in the middle of the workbench, a plurality of fixing holes matched with the buttons are formed in the rotating disc, and a discharging hole is formed in one side of a fixing disc arranged at the bottom of the rotating disc; the discharging hole is formed under one fixing hole, and a drilling mechanism used for drilling holes in the buttons is arranged on one side of the workbench. The rotating disc is arranged on the workbench, the fixing holes formed in the rotating disc are used for storing and fixing buttons, so that when the drill rod drills the buttons, the buttons do not shift, and the situation that the punching precision is not enough is avoided, and through the fixing disc arranged at the bottom of the rotating disc, when the rotating disc drives the buttons to move to the discharging holes formed in the fixing disc, the buttons can be conveniently punched. And in cooperation with a push rod on the cleaning mechanism, the buttons can be conveniently discharged from the fixing holes, manual discharging is not needed, and the button machining efficiency is improved.

Owner:岳西县海创饰品有限公司

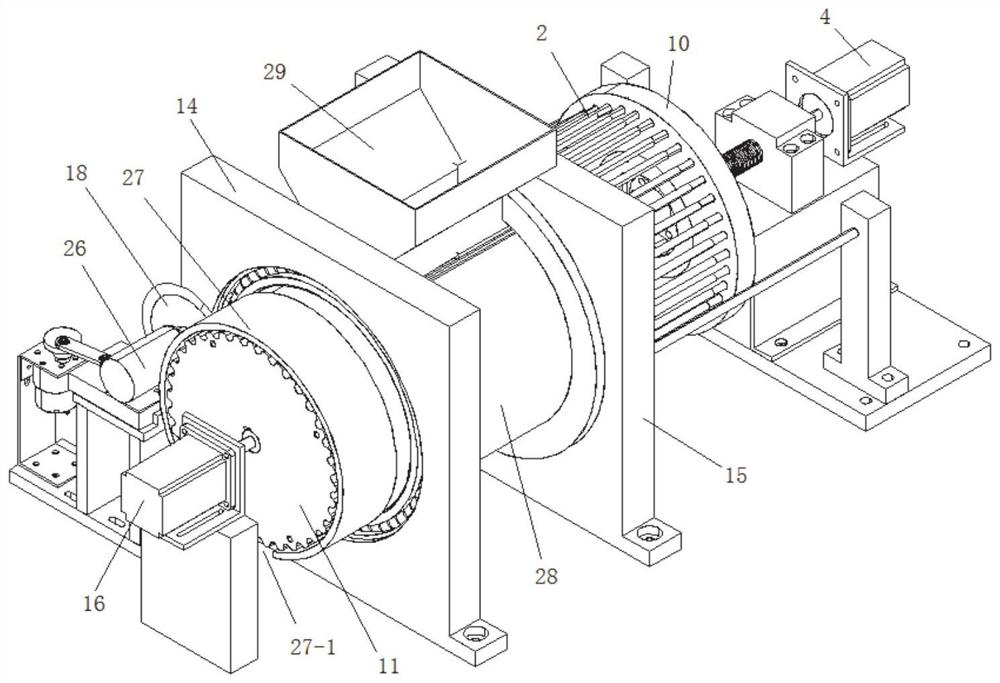

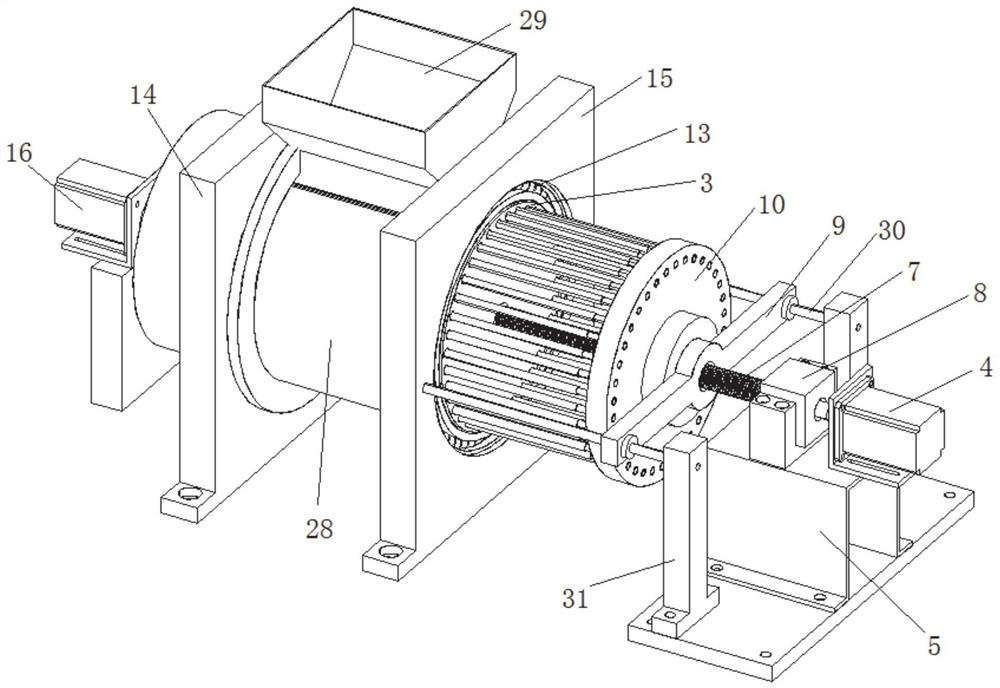

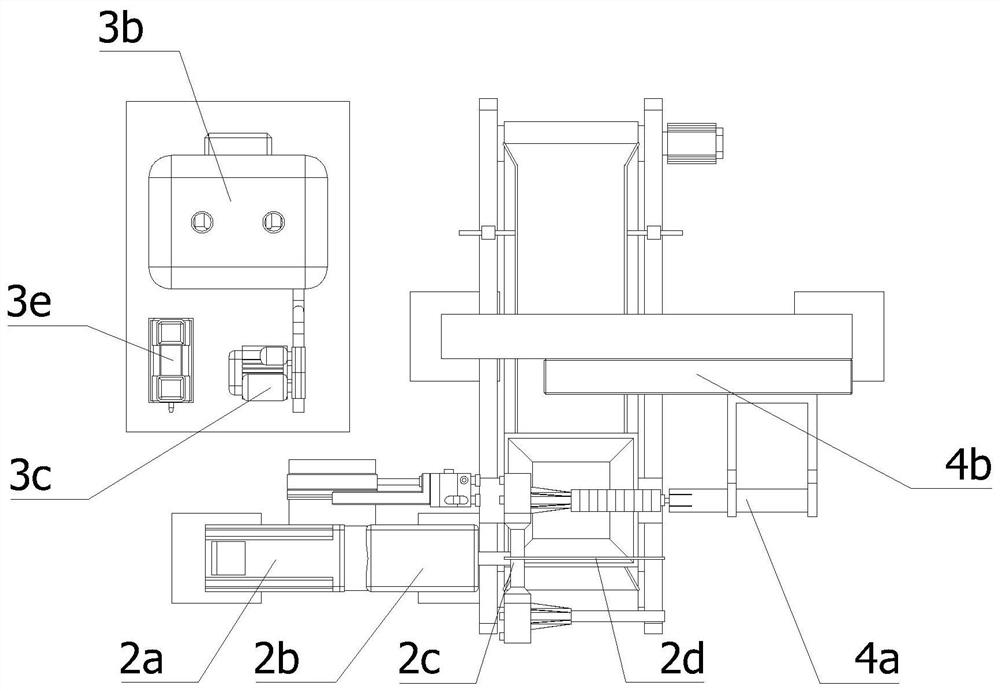

Heating cigarette base rod slitting device and working method

ActiveCN112917575AImprove cutting efficiencyReduce labor intensityMetal working apparatusGlass productionKnife bladesPhysics

The invention relates to a heating cigarette base rod slitting device and a working method. The heating cigarette base rod slitting device comprises a feeding drum wheel capable of rotating actively, wherein a first groove is formed in the surface of the feeding drum wheel, a push rod connected with a pushing mechanism extends into the first groove, a slitting drum wheel capable of rotating synchronously with the feeding drum wheel is arranged on the other side of the feeding drum wheel, a second groove is formed in the surface of the slitting drum wheel, a blade is arranged on one side of a gap between the slitting drum wheel and the feeding drum wheel and connected with a cutting mechanism, and the cutting mechanism can drive the blade to move towards the gap between the slitting drum wheel and the feeding drum wheel. The slitting device is high in working efficiency, low in labor intensity and high in slitting precision.

Owner:QINGDAO ETSONG TECH CO LTD

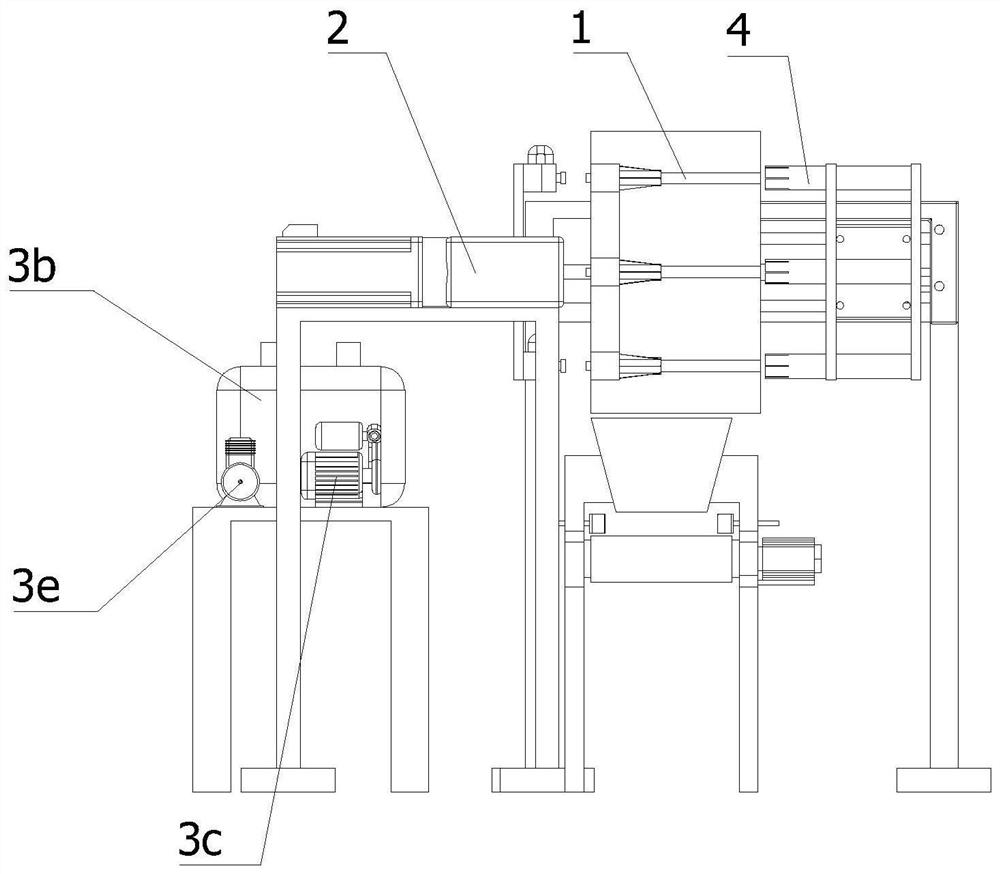

PVC insulating tape recovery processing device and production line

ActiveCN113021688AImprove production safetyIncrease productivityPlastic recyclingProduction lineAdhesive belt

The invention relates to the field of PVC insulating tape recovery equipment, in particular to a PVC insulating tape recovery processing device and a production line. The PVC insulating tape recovery processing device comprises a rack, positioning parts, a heating device and a separating device, wherein tape is placed on the positioning parts in a sleeving mode, the heating device is arranged on the rack and used for heating the positioning parts, and the separating device is arranged on the rack and used for driving one of tape parts and core parts to move relative to the positioning parts of the other one of the tape parts and the core parts. According to the PVC insulating tape recovery processing device, the multiple pieces of tape are placed on the positioning parts in a sleeving mode, then the positioning parts are heated through the heating device, heat is transmitted to the core parts and the tape parts, then the tape parts loose the stickiness for sticking the core parts, and then the tape parts and the core parts can be separated in the mode that the tape parts and the core parts are driven to move relative to the positioning parts through the separating device.

Owner:宁波市东升粘胶制品有限公司

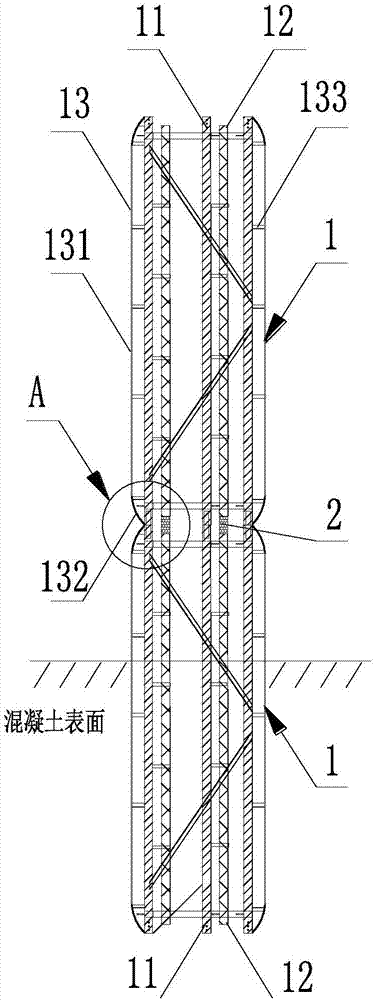

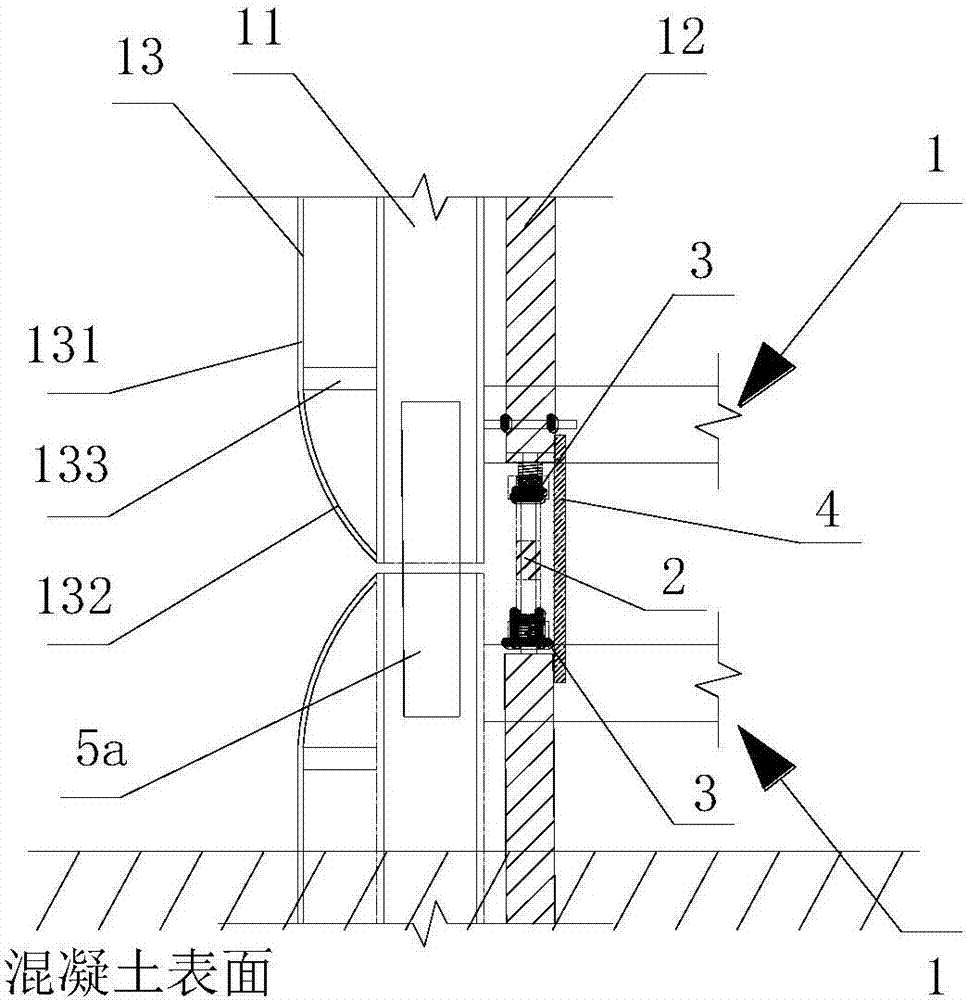

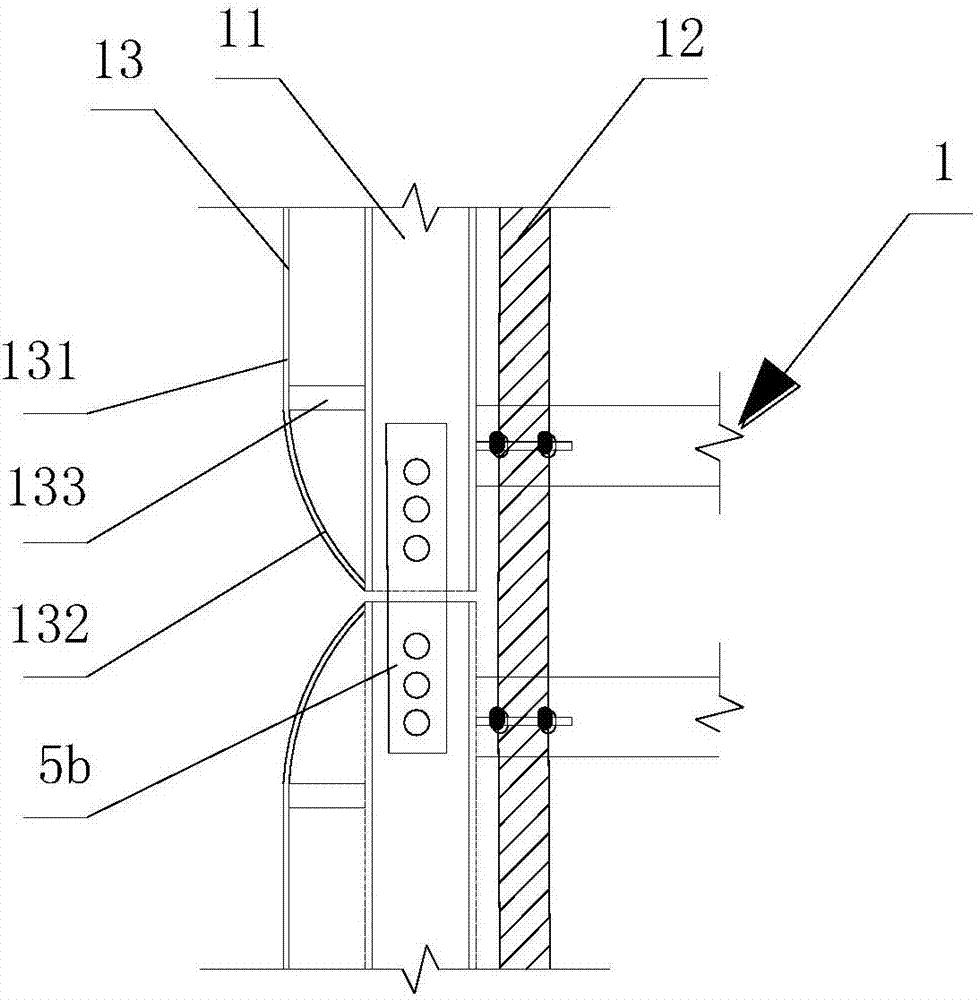

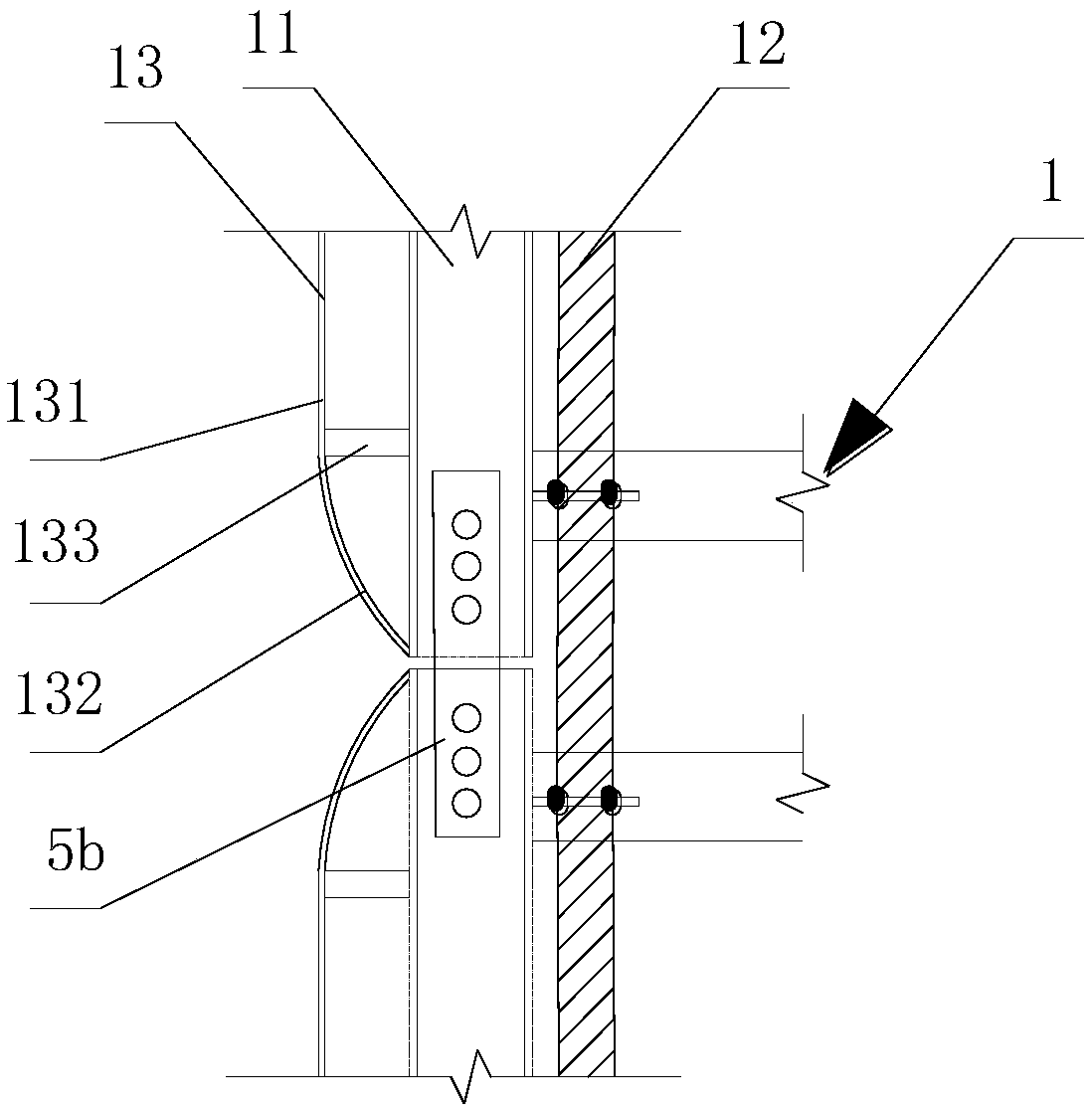

Mudjack pipe frame for steel pipe pile and layout method of mudjack pipe frame

ActiveCN107152026AImprove construction efficiencyNo need for manual cuttingBulkheads/pilesMaterial resourcesHigh pressure

The invention discloses a mudjack pipe frame for a steel pipe pile and relates to the field of bridge engineering construction. The mudjack pipe frame comprises a plurality of mudjack pipe frame sections connected with each other, wherein each of the mudjack pipe frame sections comprises a frame body; a plurality of mudjack pipes are arranged on the frame body; a high-pressure hose is arranged between the mudjack pipes of every two adjacent mudjack pipe frame sections and communicates with the mudjack pipes of the two mudjack pipe frame sections; and the frame bodies of the two mudjack pipe frame sections are connected. The mudjack pipe frame is convenient to mount and dismantle, high in construction efficiency, safe and reliable and saves manpower and material resources.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Shearing device

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Corrugated pipe fixed-length automatic cutting machine

PendingCN110465694AEasy to cutRealize automatic cuttingFeeding apparatusTube shearing machinesEngineeringFixed length

The invention discloses a corrugated pipe fixed-length automatic cutting machine. The automatic cutting machine comprises a base and a corrugated pipe body; a baffle plate is fixedly arranged on the left side of the upper end of the base; a rotary table is movably arranged on the right side of the interior of the baffle plate; a support is fixedly arranged at the position, located on the right side of the baffle plate, of the upper end of the base; a top plate is fixedly arranged at the upper end of the support; an air pressure cylinder is fixedly installed on the outer surface of the upper end of the top plate; a fixing clamp is fixedly connected to the position, located below the top plate, of the lower end of the air pressure cylinder; a cutting wheel is movably installed in the fixingclamp; a fixing seat is fixedly installed at the position, located below the cutting wheel, of the outer surface of the upper end of the base; a roller is movably installed at the upper end of the fixing seat; and a sliding seat is movably installed on the right side of the upper end of the base. According to the device, fixed-length automatic cutting of corrugated pipes with different sizes can be achieved; and the device is simple, convenient to use and practical.

Owner:无锡市锡山环宇金属软管有限公司

Continuous folding and shearing equipment for aluminum alloy door and window production

ActiveCN113732380APrevent rotationEasy to fold and cutShearing machinesMetal working apparatusEngineeringStructural engineering

The invention discloses continuous folding and shearing equipment for aluminum alloy door and window production. The continuous folding and shearing equipment comprises a machining platform, wherein a circular groove is formed in the machining platform, and a driving disc is rotationally connected into the circular groove; a folding and shearing platform is fixedly connected to the upper side wall of the driving disc, and a folding and shearing device is arranged on the folding and shearing platform; an annular groove is further formed in the machining platform, and a gear ring is rotationally connected into the annular groove; and a plurality of threaded cylinders are rotationally connected into the annular groove in the circumferential direction. The continuous folding and shearing equipment has the advantages that the angle of the folding and shearing device can be changed through the driving disc, so that when aluminum alloy needs to be folded and sheared at different angles, the folding and shearing platform does not need to be replaced, and only the driving disc needs to be started to rotate the folding and shearing device; the whole equipment is easy to operate and convenient for aluminum alloy folding and shearing use; and meanwhile, the driving disc can be fixed through devices such as the threaded cylinders and threaded rods, the driving disc is prevented from rotating after angle adjustment is completed, and the folding and shearing effect of the aluminum alloy is guaranteed.

Owner:江西守华建筑建材有限公司

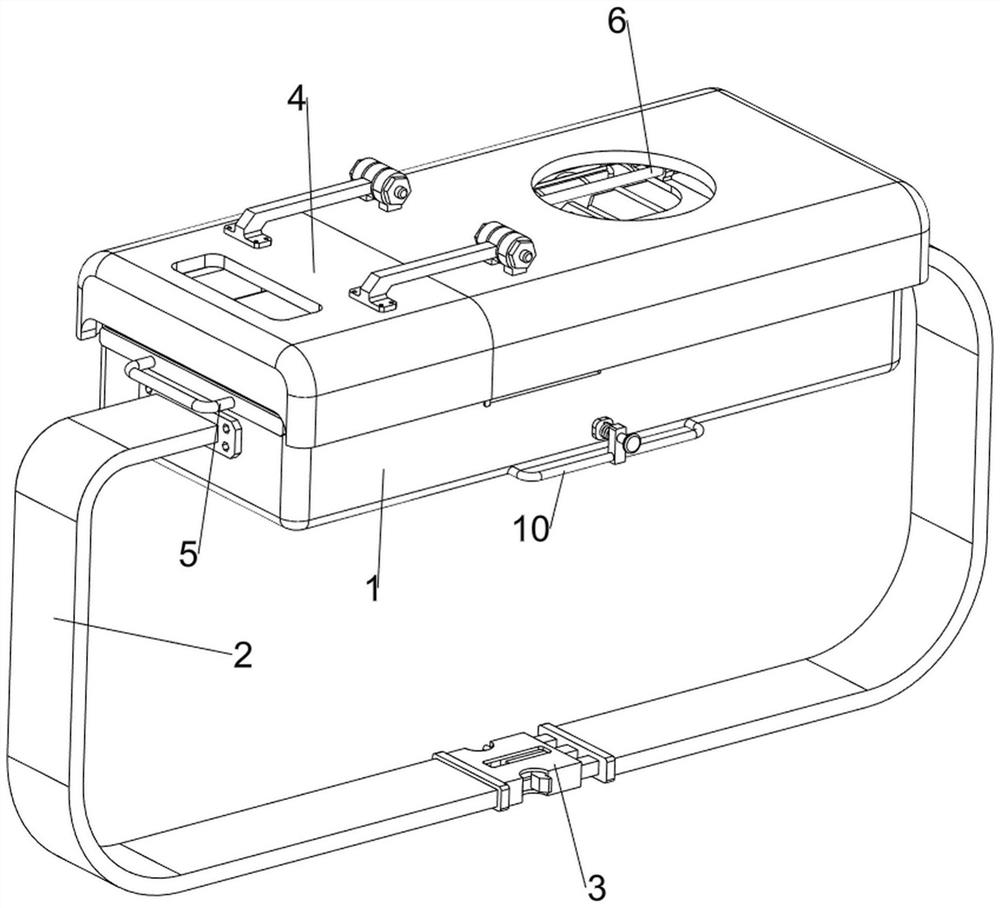

Portable biological amniotic membrane shearing device

ActiveCN113771107AShear evenlyNo need for manual cuttingLavatory sanitoryMetal working apparatusAnatomyAmniotic Sheet

The invention relates to an amniotic membrane shearing device, in particular to a portable biological amniotic membrane shearing device. The invention aims to provide the portable biological amnion shearing device which is simple and easy to operate and does not need manual shearing. According to the technical scheme, the portable biological amniotic membrane shearing device comprises straps, a clamping buckle, a rotating frame and a charging mechanism; a shell is symmetrically provided with the straps used for carrying the portable biological amniotic membrane shearing device; the clamping buckle is arranged on the lower side of the strap on one side, the clamping buckle is matched with the strap on the other side; the rotating frame is rotationally arranged on one side of the top of the shell, the rotating frame is matched with the shell; and the charging mechanism is arranged on one side in the shell. People flatly spread an amniotic membrane on a material placement plate for shearing, and after the amniotic membrane is sheared, people move the material placement plate to the left side, so that the amniotic membrane is in contact with a scraping plate.

Owner:JIANGXI KEXING BIOLOGICAL ENG CO LTD

A kind of numerical control machine tool with material guide

ActiveCN111890103BNo need for manual cuttingReduce laborMetal working apparatusMaintainance and safety accessoriesNumerical controlMachine

The application relates to a numerically controlled machine tool with a material guide, and relates to the field of machine tools, including a frame and a chuck for clamping workpieces. The carriage is provided with a tool, and the chuck is provided with a plurality of clamping blocks along the circumference for clamping the workpiece. The movable direction of the clamping blocks is along the radial direction of the chuck, and the center of the chuck is set There is an installation hole, and an elastic piece is arranged in the installation hole. The elastic force direction of the elastic piece is along the axial direction of the chuck, and the elastic piece can eject the workpiece on the chuck; The feedway, the carriage can make the guideway face the chuck by sliding. The CNC machine tool can automatically shoot the workpiece out of the chuck, and the workpiece is guided by the material guide channel and then enters the receiving tray for storage, without manual unloading, which reduces the amount of manual labor; by setting the feeding mechanism, the workpiece can be automatically loaded.

Owner:台州一鼎数控机床有限公司

Plate punch forming device for hardware product manufacturing

InactiveCN114733946AReduce labor intensityNo manual operationShaping toolsMetal-working feeding devicesHydraulic cylinderThin slab

The plate punch forming device for hardware product manufacturing comprises a rack, a first hydraulic cylinder and an empty groove, a groove is formed in the surface of the rack, a lower die is arranged at the top of the groove, a sliding groove is formed in the side wall of an L-shaped fixing frame, and a transverse plate is arranged in the sliding groove; the first hydraulic cylinder is arranged at the top of the L-shaped fixing frame, and a movable plate is fixed to the bottom of the first hydraulic cylinder. The plate punch forming device for hardware product manufacturing is provided with a connecting rod and a transverse plate, a second hydraulic cylinder drives a carrying disc to ascend, a suction cup set at the bottom of the transverse plate adsorbs a thin plate on the carrying disc, and when a first hydraulic cylinder drives a movable plate and an upper mold to ascend, the movable plate can drive the transverse plate to move rightwards through the connecting rod on the side wall of the movable plate; according to the thin plate feeding device, the thin plate below the suction cup set can be moved to the position above the lower die, then the thin plate can be fed, manual operation is not needed during use, the labor intensity of workers is reduced, and the safety during use is improved.

Owner:无锡凯铭智能科技有限公司

Garden deadwood breaking device

PendingCN114311165ANo need for manual cuttingEasy to cleanProfiling/shaping machinesBark-zones/chip/dust/waste removalWorkbenchSupport plane

The invention relates to a deadwood breaking device, in particular to a garden deadwood breaking device. The technical problem of the invention is to provide the garden deadwood breaking device capable of quickly cutting deadwood. According to the technical scheme, the garden deadwood breaking device comprises a bottom plate, supporting columns, a workbench, a first supporting frame, a first movable rod, a breaking rod, a pushing mechanism, a conveying mechanism and a cutting mechanism, the four supporting columns are evenly arranged on one side of the top of the bottom plate, the workbench is arranged between the tops of the supporting columns, and the first supporting frame is arranged on one side of the workbench; and a first movable rod is slidably arranged on the first supporting frame, a breaking rod is slidably arranged on one side of the first movable rod, a pushing mechanism is arranged on the other side of the top of the bottom plate, and the pushing mechanism is matched with the first movable rod. The device has the beneficial effects that the transmission mechanism works to drive deadwood to move leftwards for cutting, and manual pushing is not needed.

Owner:陈桂连

An intelligent conveying device for food and beverage production

ActiveCN112357866BPrevent production process impactImprove work efficiencyConveyorsLiquid bottlingStructural engineeringBottle

Owner:BENGBU KUNPENG FOOD & BEVERAGE

A grouting pipe frame for steel pipe piles and its laying method

ActiveCN107152026BImprove construction efficiencyNo need for manual cuttingBulkheads/pilesBridge engineeringMaterial resources

The invention discloses a mudjack pipe frame for a steel pipe pile and relates to the field of bridge engineering construction. The mudjack pipe frame comprises a plurality of mudjack pipe frame sections connected with each other, wherein each of the mudjack pipe frame sections comprises a frame body; a plurality of mudjack pipes are arranged on the frame body; a high-pressure hose is arranged between the mudjack pipes of every two adjacent mudjack pipe frame sections and communicates with the mudjack pipes of the two mudjack pipe frame sections; and the frame bodies of the two mudjack pipe frame sections are connected. The mudjack pipe frame is convenient to mount and dismantle, high in construction efficiency, safe and reliable and saves manpower and material resources.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

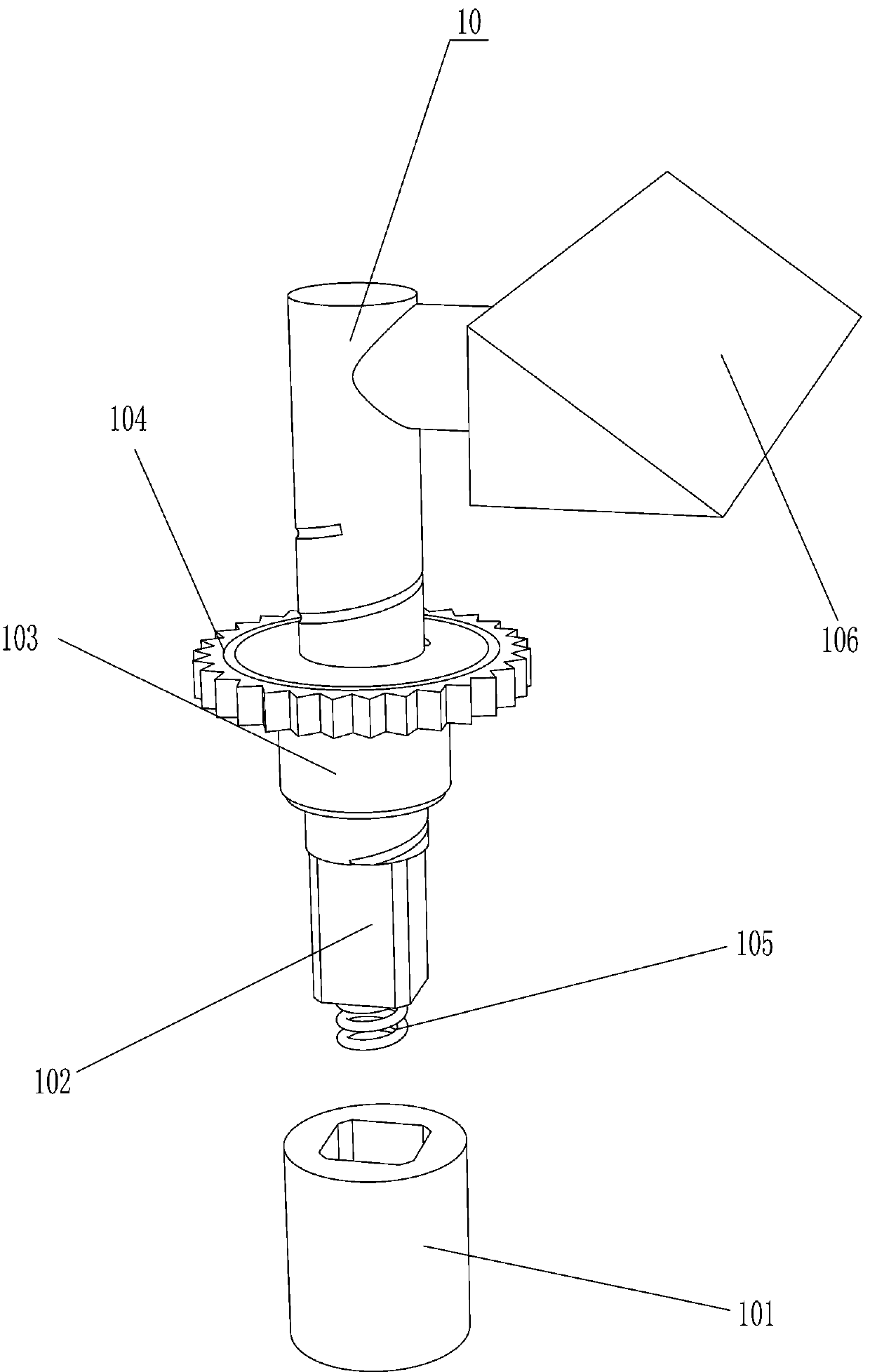

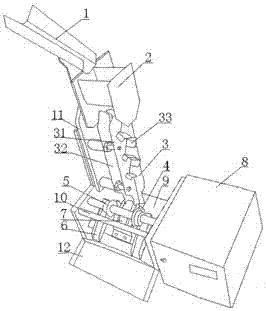

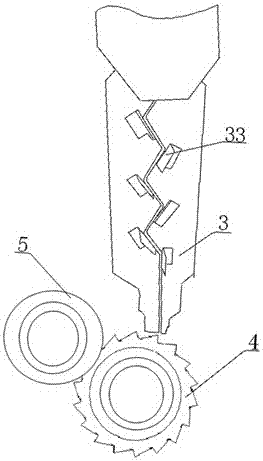

High current silicon pile cutting machine

The invention relates to a heavy current silicon stack foot cutting machine comprising a feeding sieve, a charging hopper, a rectifying discharging mechanism, ratchets, cutter wheels, waste material outlets, a press plate, a motor and a control box as well as a machine base. The machine base is U-shaped; one side of the upper end of the machine base is connected with a cross rod; one side of the cross rod is provided with a cutting wheel shaft disposed in the middle of the machine base; two cutting wheels are arranged on the cutting wheel shaft; a ratchet shaft slantwise under the cutting wheel shaft is placed in the middle of the machine base; two ratchets are arranged on the ratchet shaft; the lower end of the cross rod is provided with a transverse support; the press plate is mounted in the middle of the transverse support; the press plate is arranged over the ratchets and between the two cutting wheels; the rectifying discharging mechanism is arranged over the ratchets; the charging hopper is arranged over the rectifying discharging mechanism; the feeding sieve over the charging hopper is slantwise arranged on the top end of a side plate; the finished product outlet under the ratchets is formed on the upper end of the machine base; and the control box is mounted on one side of the machine base. The heavy current silicon stack foot cutting machine is advantaged by simple design, convenient use, free of manual cutting work, small labor intensity, high efficiency, great lead length precision and satisfaction to client demands.

Owner:江苏皋鑫电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com