High-efficient automatic film blowing device capable of preventing electrostatic interference

A static interference and film device technology, applied in the field of high-efficiency automatic film blowing devices, can solve problems such as environmental pollution and physical injury of operators, and achieve the effects of scientific and reasonable structure, reduced emissions, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

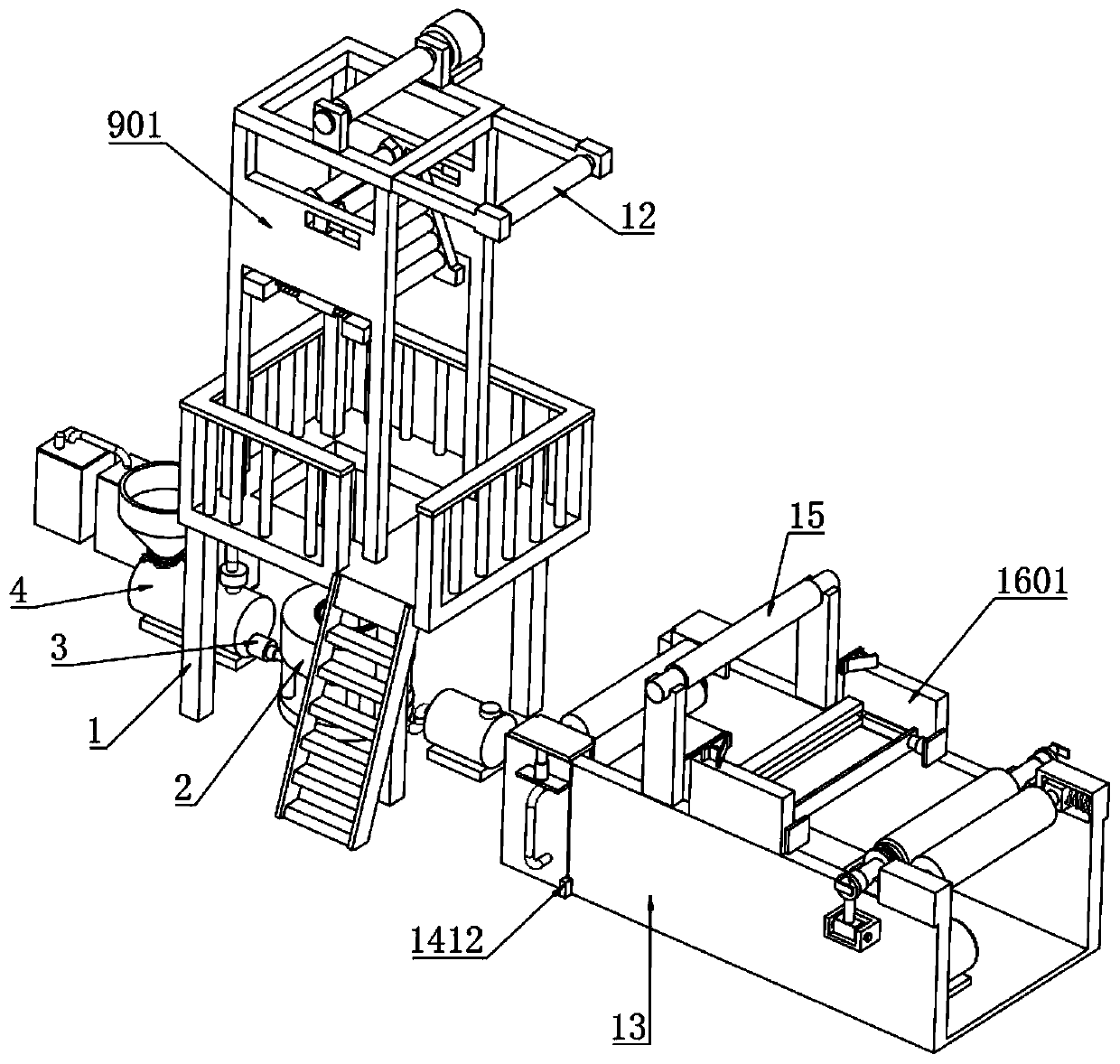

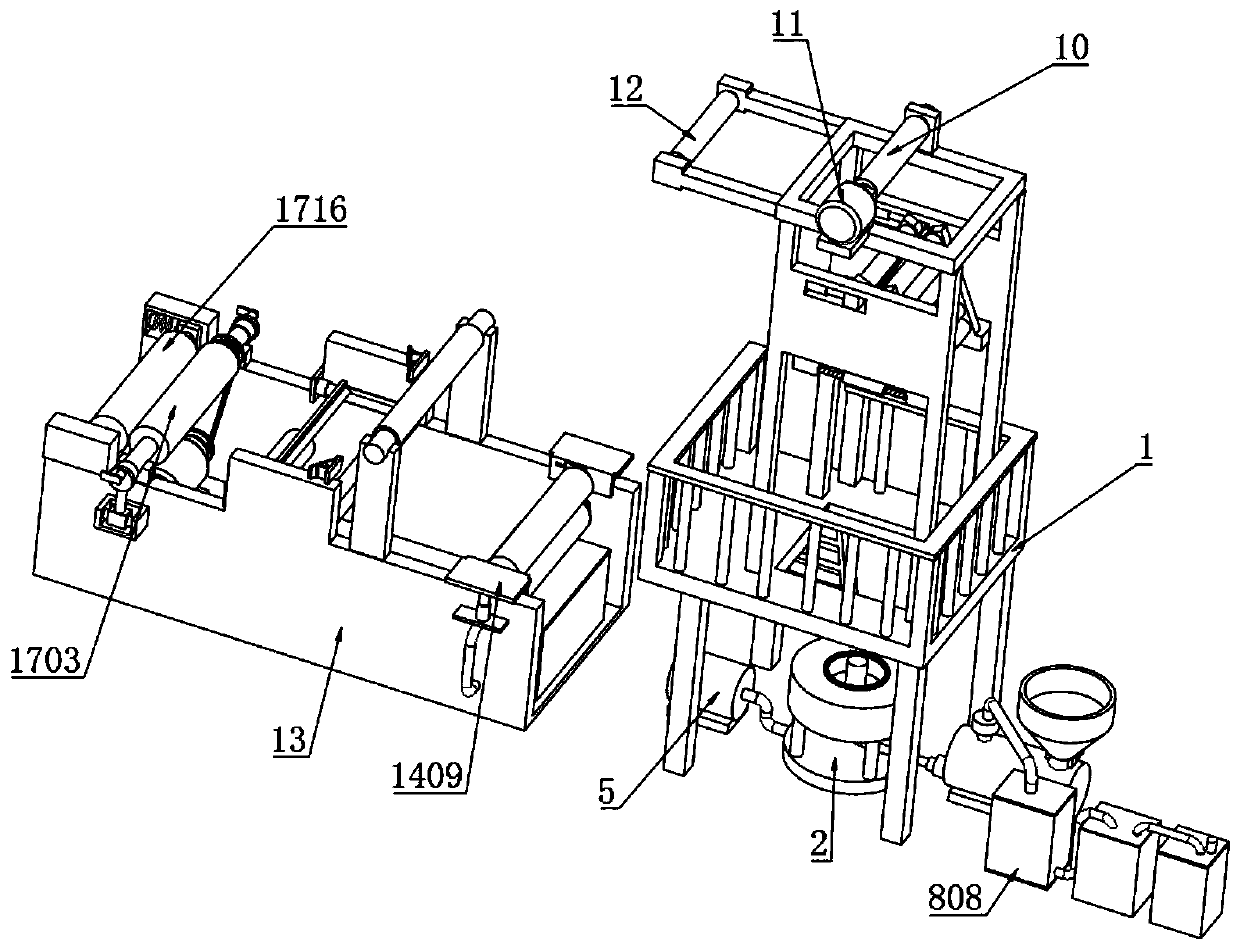

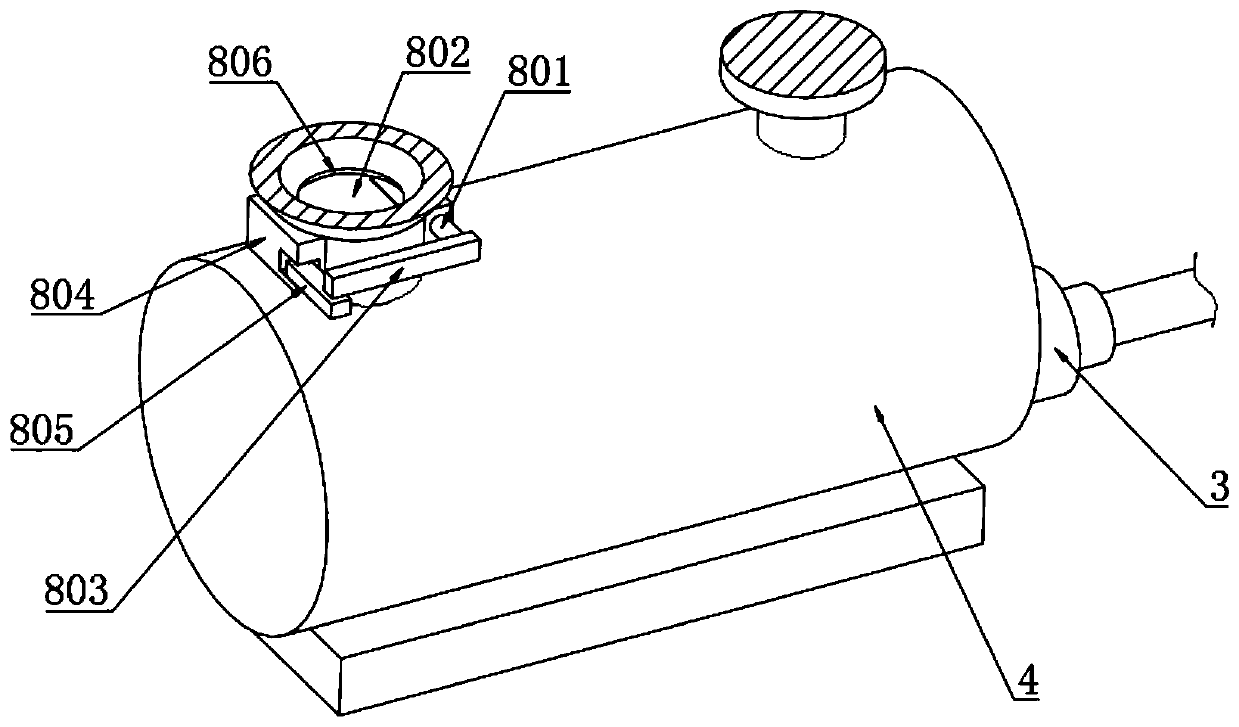

[0054] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a high-efficiency automatic film blowing device for preventing electrostatic interference, comprising a frame 1, a film blowing die 2 is fixedly installed in the middle of the bottom end of the frame 1, and the melted plastic is blown by a blower 5 Blowing into plastic film, one end of the top of the film blowing die 2 is fixedly connected with a squeeze pump 3, and one end of the squeeze pump 3 is fixedly installed with a melt tank 4 to melt the raw material, and then use the squeeze pump 3 to transport to Inside the film blowing die 2, the blower 5 is fixedly connected to the bottom end of the blowing film die 2 away from the squeeze pump 3, and the injection pipe 6 is fixedly connected to the top end of the melting tank body 4, and the top of the injection pipe 6 A storage hopper 7 is fixedly installed, and an exhaust gas removal mechanism 8 is installed on the top of the mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com