Heating cigarette base rod slitting device and working method

A base rod and cigarette technology, applied in the field of heated cigarette base rod cutting device, can solve the problems of high labor intensity, inaccurate control of base rod cutting length, poor cutting precision, etc., to reduce labor intensity and improve cutting Efficiency, the effect of ensuring cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

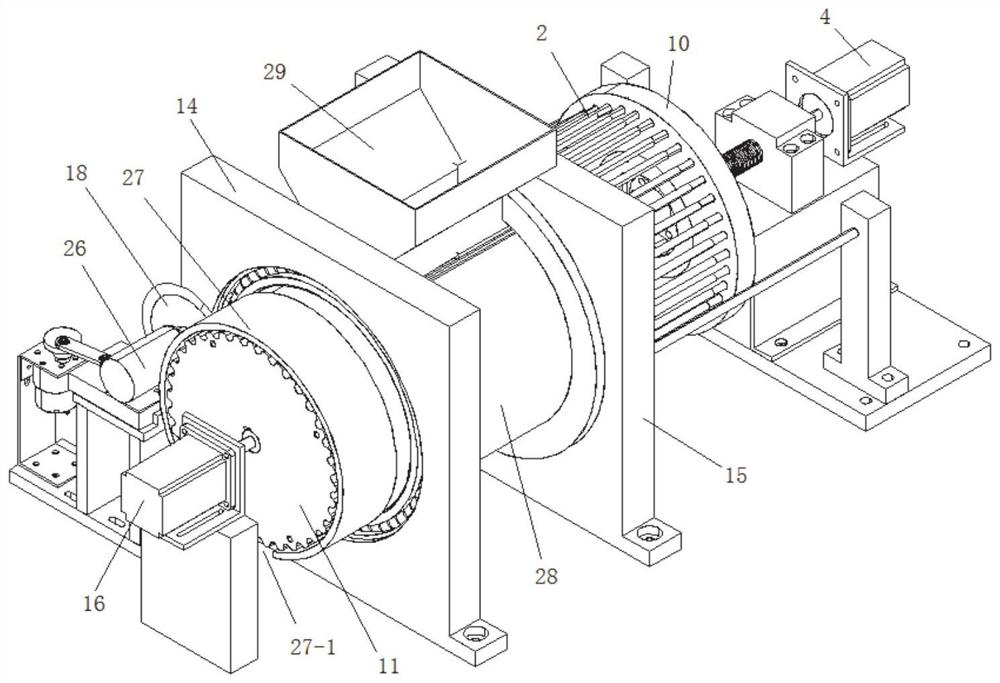

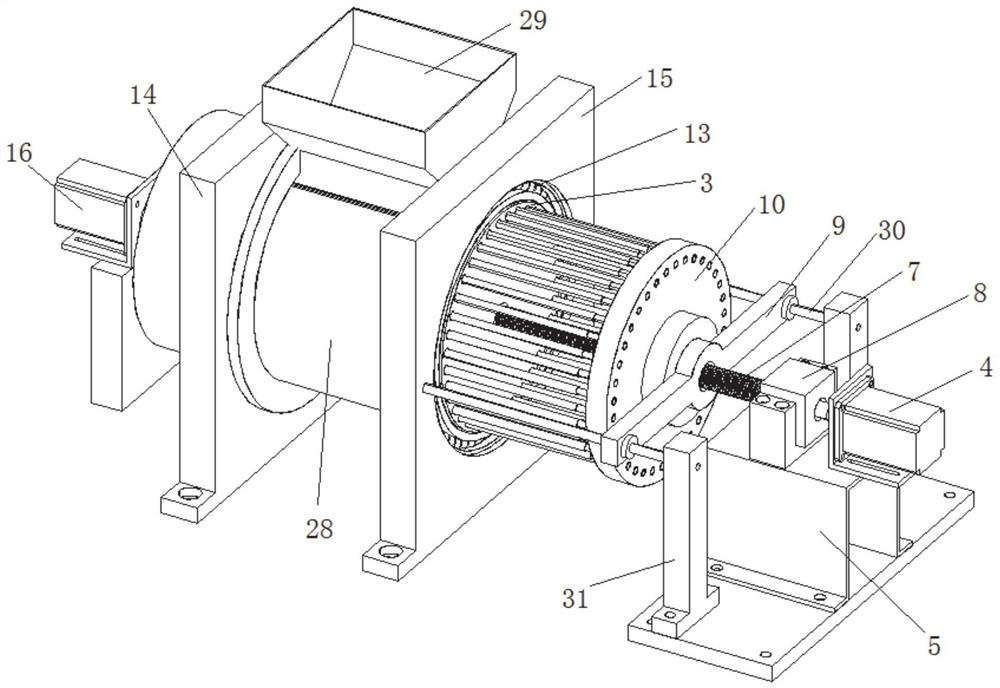

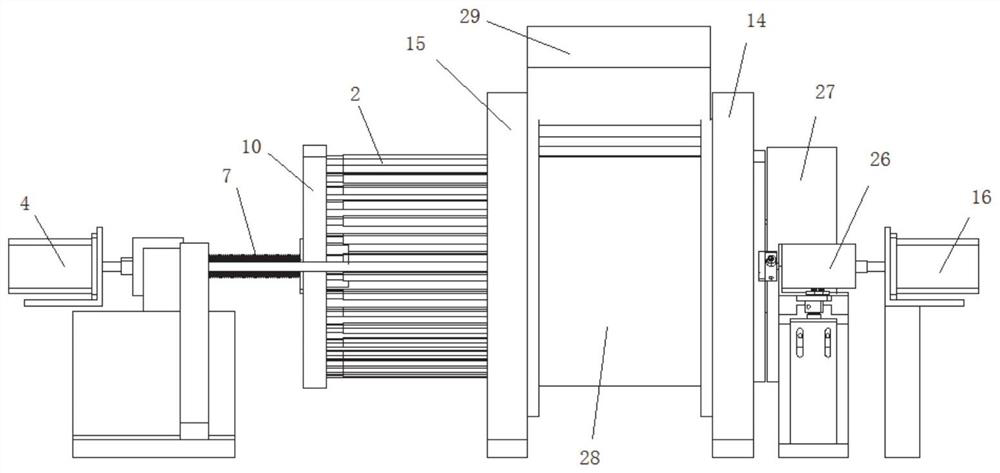

Image

Examples

Embodiment 2

[0044] This embodiment discloses a working method of a heated cigarette base rod cutting device:

[0045] The staff sends the base rod to be cut into the first groove of the feeding drum through the hopper and the feeding port, the second protective cover can prevent the base rod from falling out of the first groove, the first motor works, Drive the screw to rotate, the screw drives the slider to move along the axis of the screw, the slider drives the adjustment plate to move along the axis of the screw, the adjustment plate drives the push rod to move along the axis of the screw in the first groove, and the push rod pushes The base rod passes through the first flange through the first through hole and enters the second groove of the slitting drum. At this time, part of the base rod is in the second groove, the remaining part is in the first groove, and the second The motor drives the slitting drum and the feeding drum to rotate, the base bar rotates to the cutting station, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com