High current silicon pile cutting machine

A high-current, cutting machine technology, applied in the field of high-current silicon stack cutting machine, can solve the problems of large lead length error, high labor intensity, low efficiency, etc., and achieve the effect of low labor intensity, simple design and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

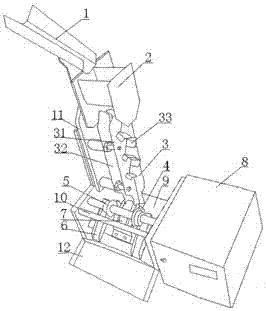

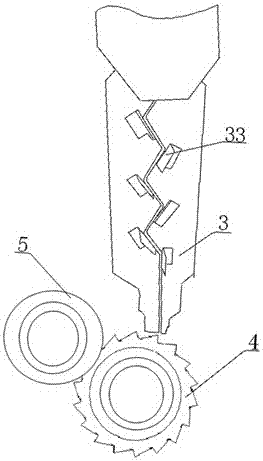

[0012] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

[0013] With reference to the accompanying drawings, the high-current silicon stack cutting machine includes a feeding screen 1, a feeding hopper 2, a correcting and unloading mechanism 3, a ratchet 4, a knife wheel 5, a waste outlet 6, a pressing plate 7, a motor, a control box 8 and a machine. Seat 9 and machine base 9 are U-shaped, and one side of the upper end of machine base 9 is connected by cross bar 10, and one side of cross bar 10 has cutter wheel shaft installed in the middle of machine base 9, two cutter wheels 5 are housed on the cutter wheel shaft, and the cutter wheel shaft There is a ratchet shaft installed in the middle of the machine base obliquely below. Two ratchets are installed on the ratchet shaft. A cross brace is installed at the lower end of the cross bar 10. A pressure plate 7 is installed in the middle of the cross bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com