Square tube material cutting device for machining

A technology of mechanical processing and cutting device, which is applied in the field of mechanical processing, and can solve problems such as indentation or bulging of the incision, poor fixing effect, and affecting the quality of square tube cutting, so as to improve stability, stable clamping, and avoid incision deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

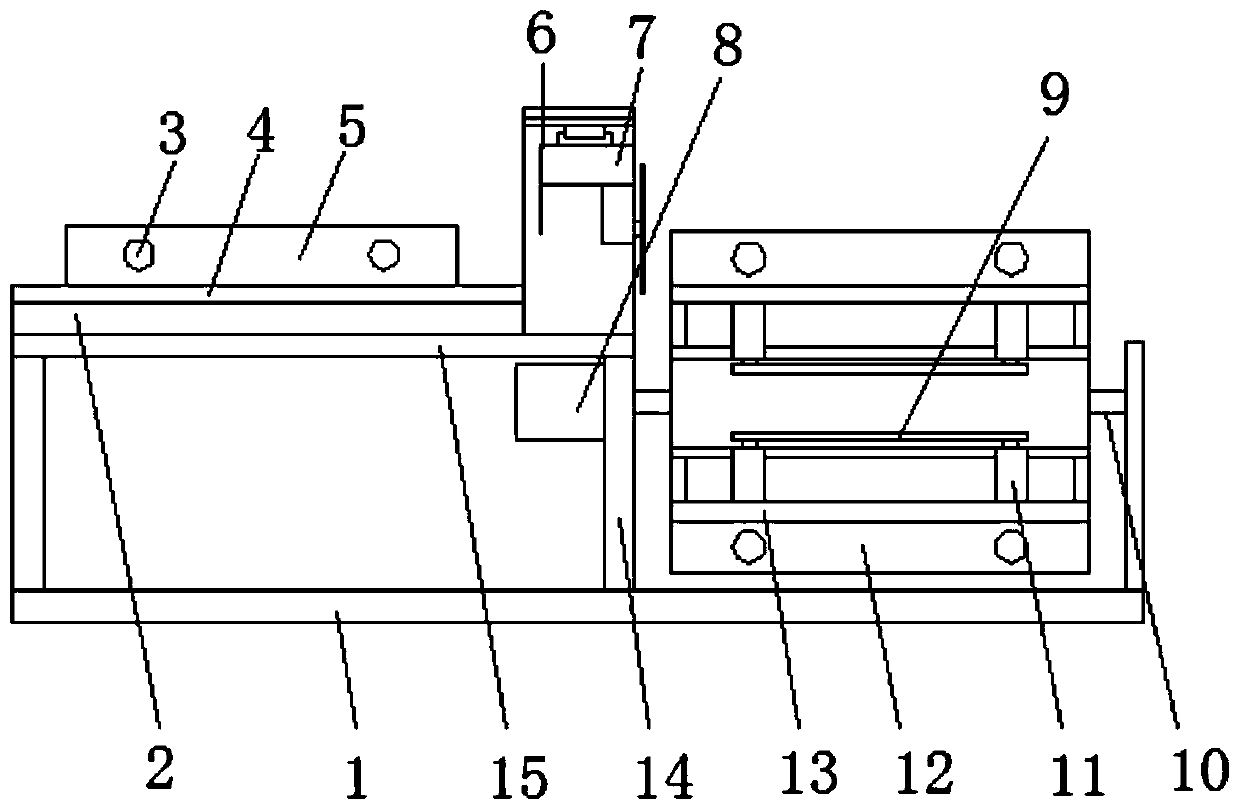

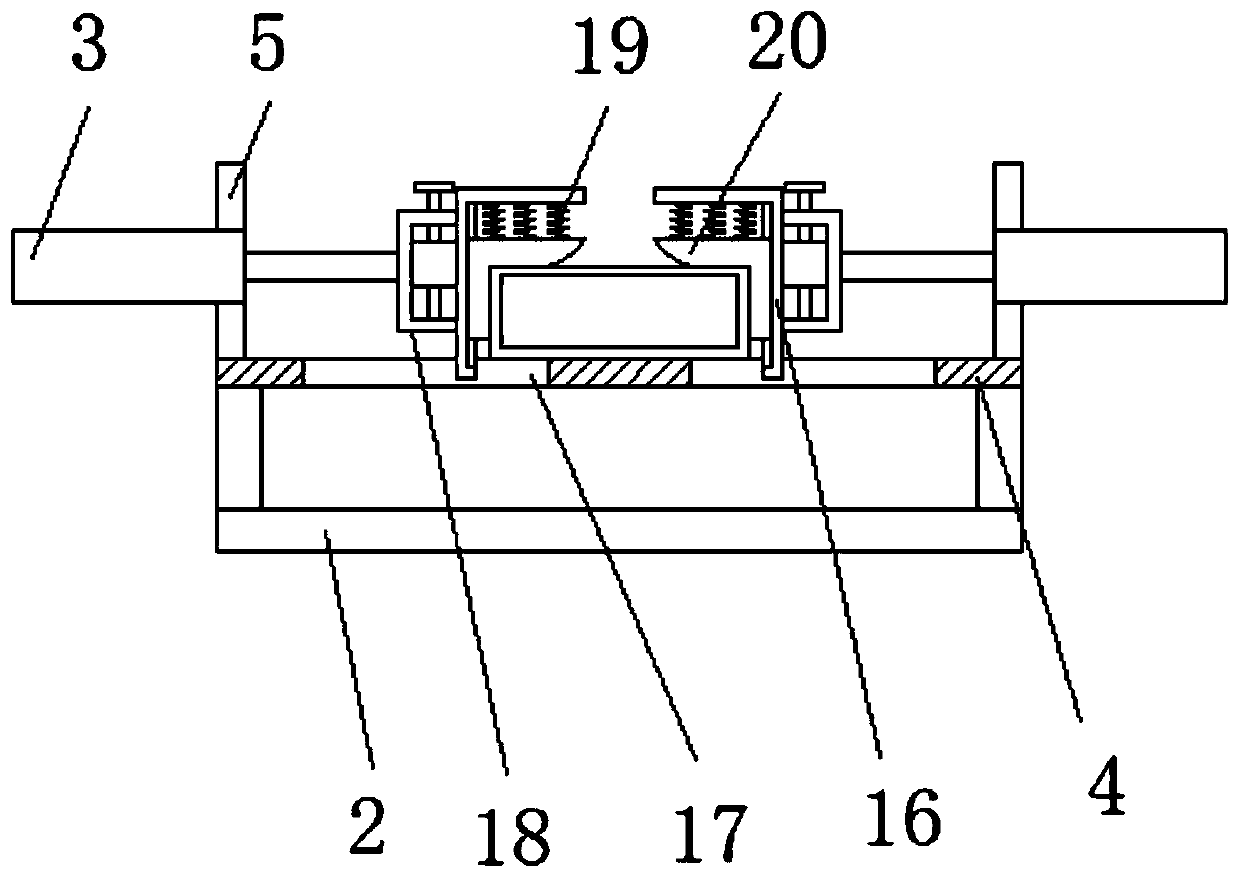

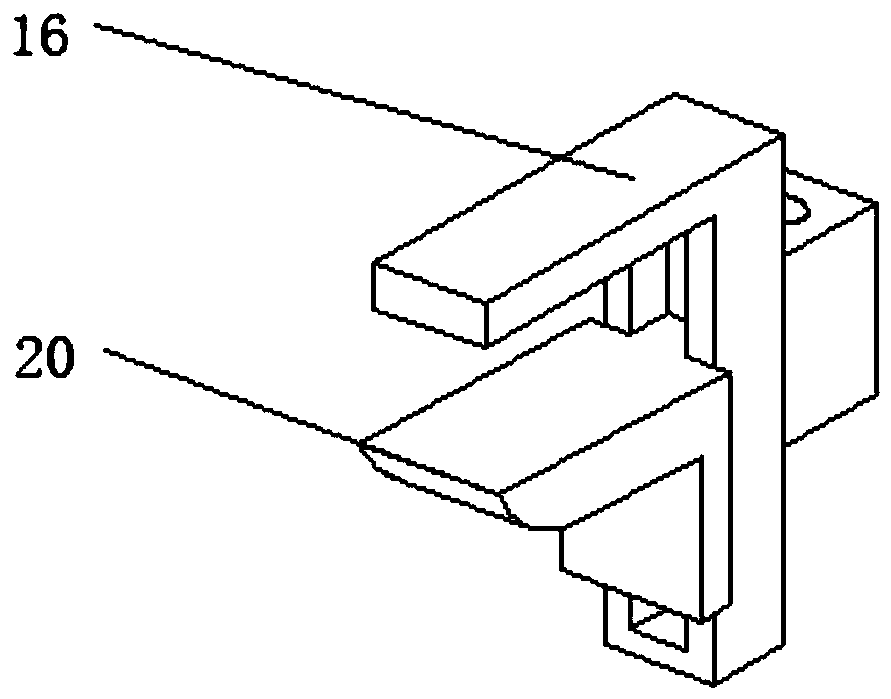

[0027] refer to Figure 1-5 , a square tube material cutting device for mechanical processing, comprising a base 1, two support plates 14 are fixedly installed on the top of the base 1, and a support plate 15 is fixedly installed between the tops of the two support plates 14, and the support plate The top of 15 is fixedly installed with casing 2, and the top of casing 2 is fixedly installed with feed slide table 4, and both sides of the top of feed slide table 4 are fixedly installed with side plate 5, and the sides of side plate 5 are all fixed. A plurality of staggered main electric push rods 3 are installed, the end of the movable rod of the main electric push rod 3 is fixedly equipped with an adjustment mechanism 18, and the side of the adjustment mechanism 18 is fixedly installed with an inverted L-shaped movable seat 16, the movable seat The bottom of 16 is fixedly installed with a plurality of springs 19, and the bottom of spring 19 is fixedly installed with the fasteni...

Embodiment 2

[0036] refer to Figure 1-4 with Image 6 , a square tube material cutting device for mechanical processing. Compared with Embodiment 1, this embodiment also includes: a fixed-length mechanism fixedly installed inside the blanking mechanism, and the fixed-length mechanism includes an inverted T set on the top of the plate body 13 Type structure slot 21, and the top edge of the slot 21 is provided with a scale 24, the inside of the slot 21 is plugged with a movable plate 22 by fastening bolts, and the top of the movable plate 22 is fixedly equipped with a fixed length plate 23.

[0037] In this embodiment: when using the blanking mechanism for blanking, the staff can adjust the positions of the movable plate 22 and the fixed-length plate 23, and when the rectangular square tube is inserted, its end is pushed against the fixed-length plate 23 to realize Cut-to-length work on rectangular square tubes, increasing the functionality of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com