Numerical control machine tool with material guiding track

A technology of CNC machine tools and material guides, applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of large manual labor and achieve the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-5 The application is described in further detail.

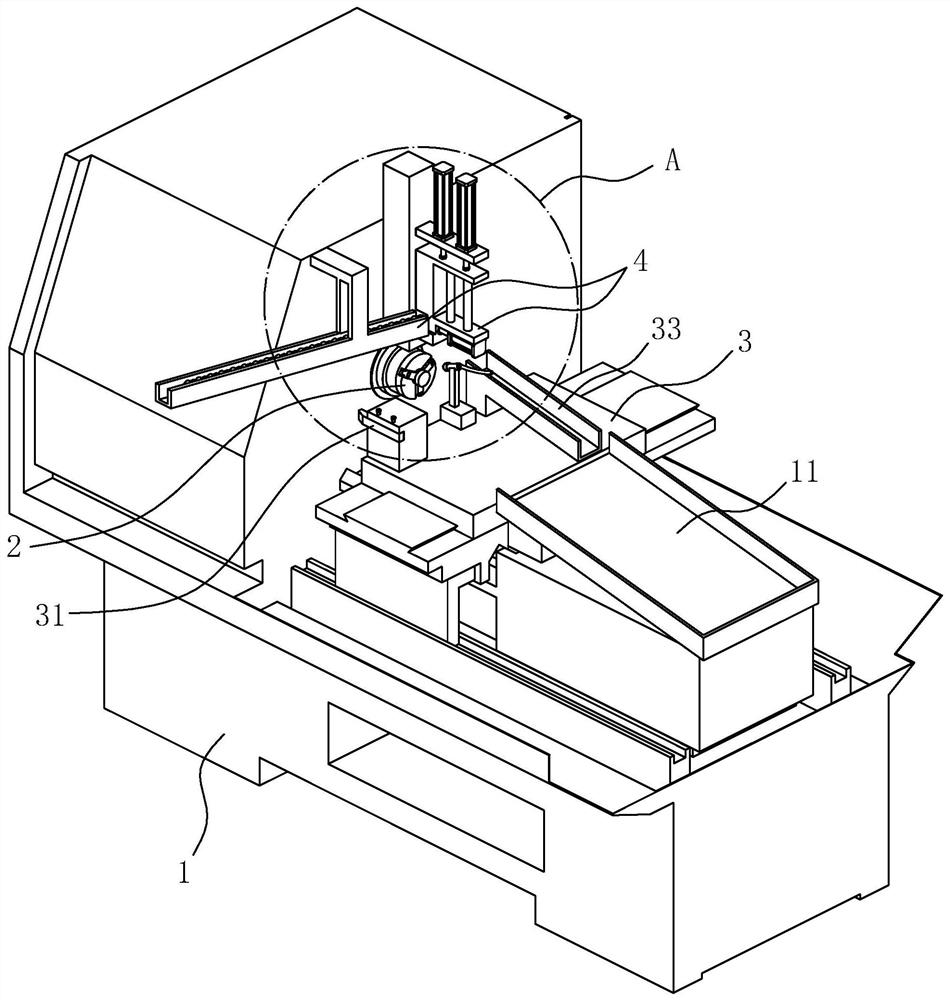

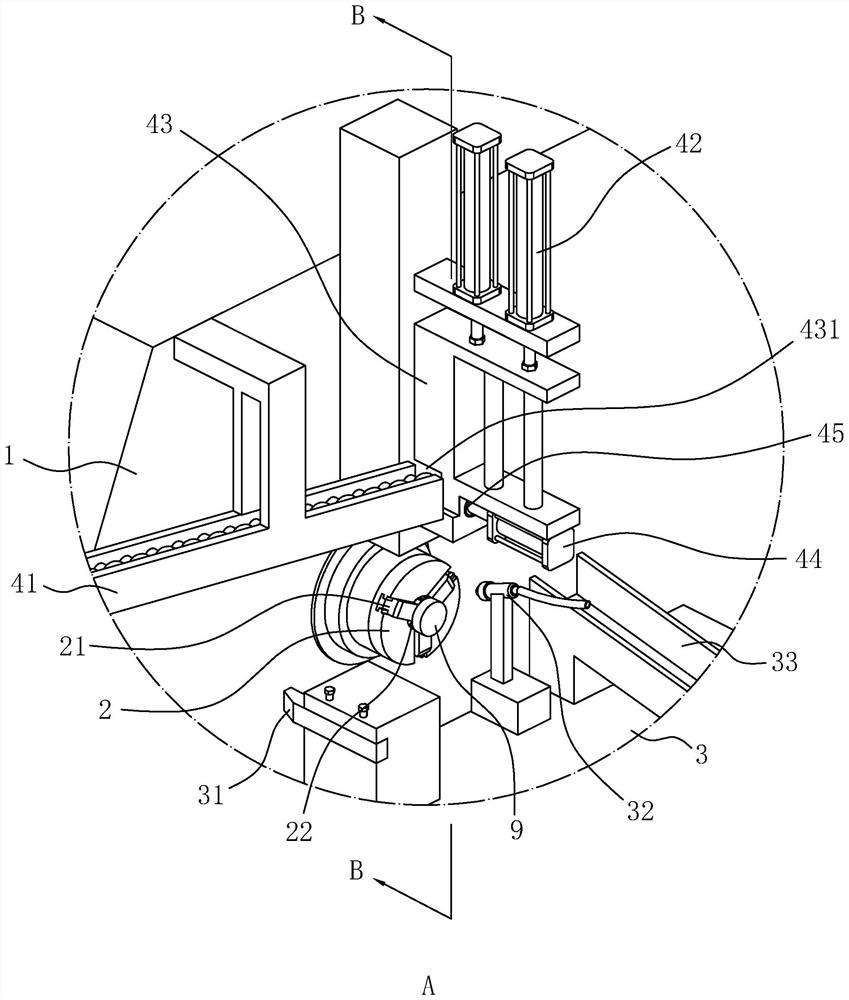

[0037] The embodiment of the present application discloses a numerically controlled machine tool with a material guide. refer to figure 1 and figure 2 , a kind of numerically controlled machine tool with guideway comprises frame 1, the chuck 2 that is used to clamp workpiece 9, the carriage 3 that is slidably arranged on the frame 1, is fixed with cutting tool 31 on the carriage 3; Frame 1 It is also equipped with a feeding mechanism 4 and a receiving tray 11 for placing the finished workpiece 9 .

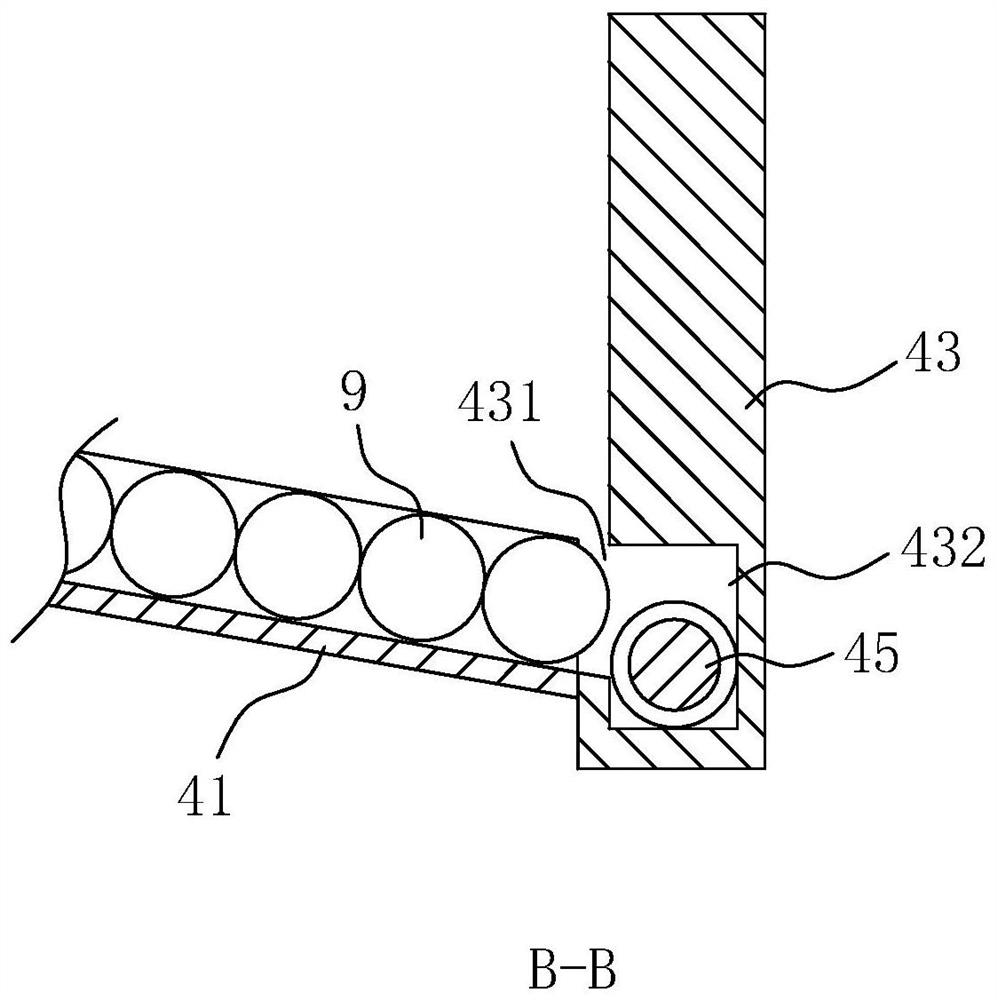

[0038] The chuck 2 is driven and rotated by a servo motor, and the chuck 2 is provided with a plurality of clamping blocks 21 for clamping the workpiece 9 along the circumferential direction. Towards, the center of the chuck 2 is provided with a mounting hole 22, and the mounting hole 22 is used for inserting the end of the workpiece 9. The clamping block 21 is commonly known as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com