Shearing device

A technology of shearing device and shearing mechanism, applied in the field of shearing device of gate, can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

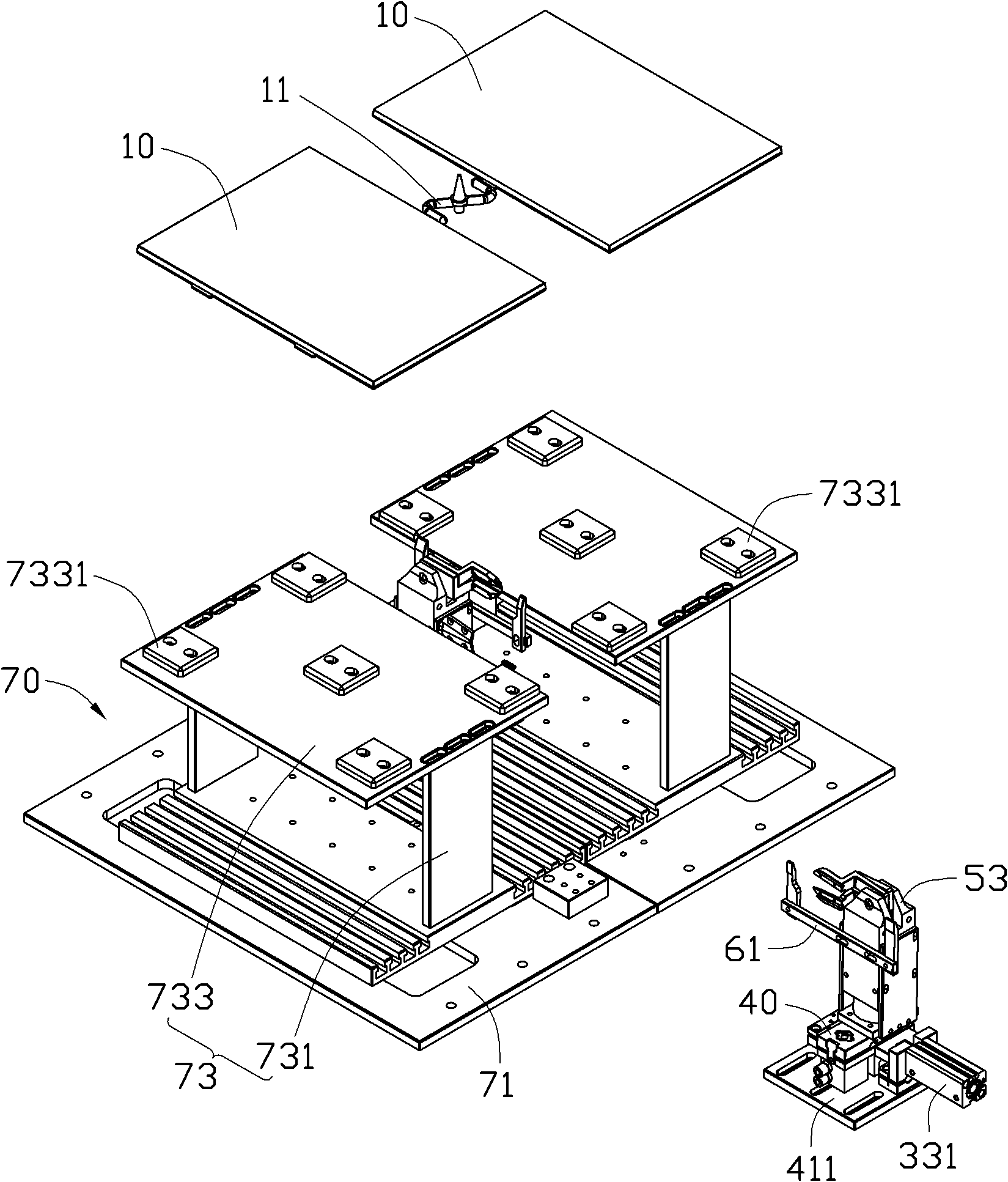

[0026] see figure 1 The shearing device of the present invention is used to shear a gate 11 connected between two plastic parts 10, and its preferred embodiment includes a bottom plate 20, a pushing mechanism 30 fixed on the bottom plate 20, a An adjusting mechanism 40 on the pushing mechanism 30 , a shearing mechanism 50 fixed together with the adjusting mechanism 40 , and an auxiliary adjusting mechanism 60 fixed on the shearing mechanism 50 .

[0027] The plastic part 10 is placed on a base 70 . The base 70 includes a base 71 and a step 73 fixed on the base 71 . The step 73 includes a fixed plate 731 fixed with the base plate 71 and a flat plate 733 fixed on the upper edge of the fixed plate 731 . Five positioning pieces 7331 are installed on the flat plate 733 , and the positioning pieces 7331 are used for positioning the plastic part 10 .

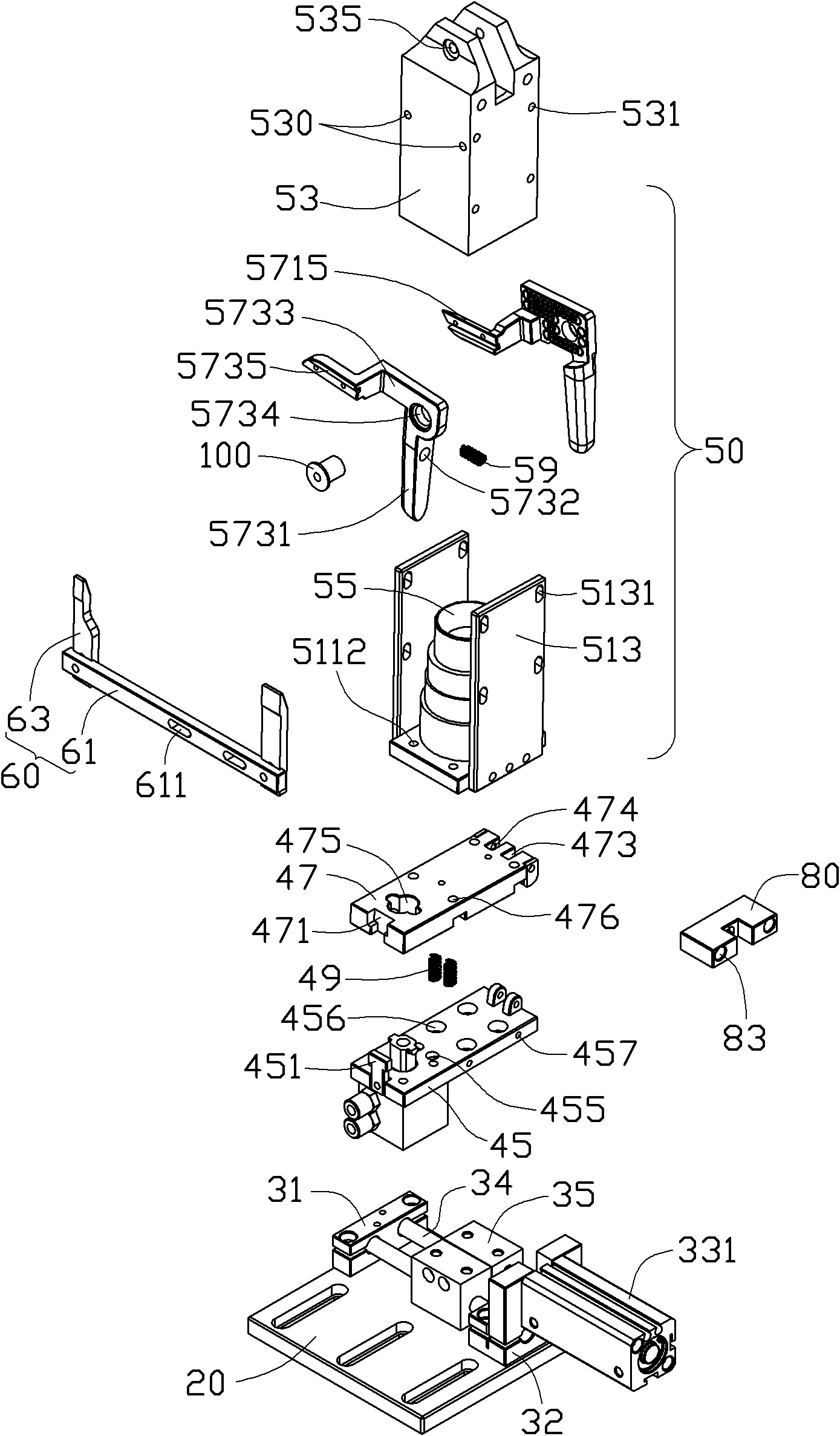

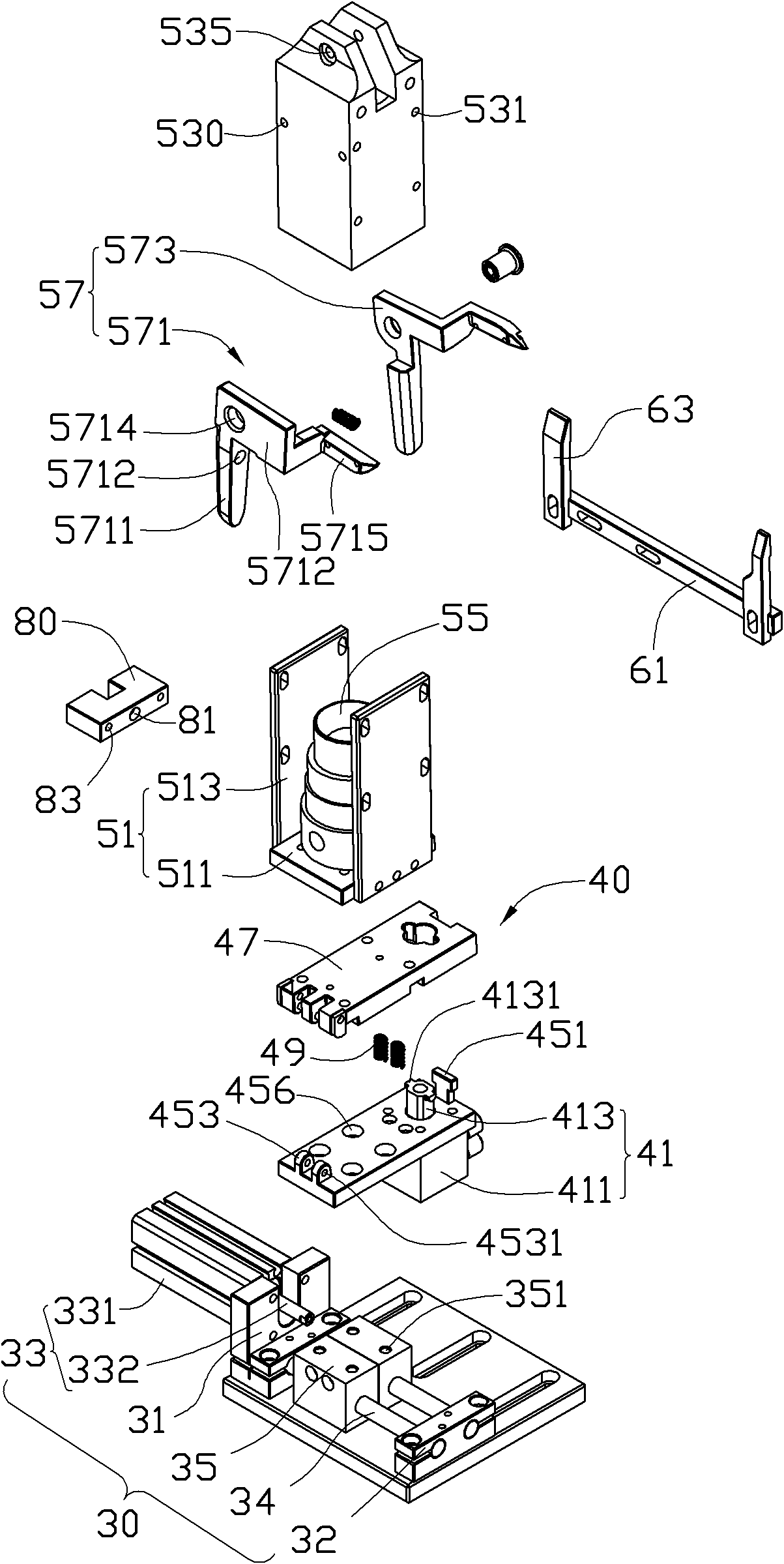

[0028] see figure 2 , image 3 and Figure 4 , the pushing mechanism 30 includes two fixing seats 31, 32 fixed on the base pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com