Height adjustable PCB clamping device

A PCB board and clamping device technology, applied in the field of height-adjustable PCB board clamping devices, can solve the problems of inconvenient size change, unchangeable height, low operation efficiency, etc., and achieve convenient connection to a PCB board collection device or a conveying device. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

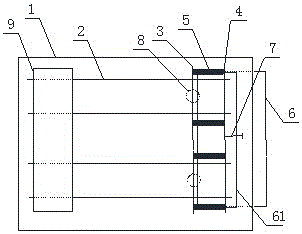

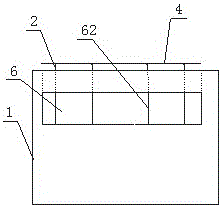

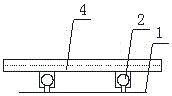

[0032] Figure 1 to Figure 4 Shows a height-adjustable PCB board clamping device provided by this embodiment, which includes a workbench 1, a guide rail 2, a clamping plate, and a board exit channel 6, wherein,

[0033] The guide rail 2 is fixed on the workbench 1. One end of the guide rail 2 is provided with a placement machine 9, and the board exit channel 6 is provided on the workbench 1 below the other end of the guide rail 2. The guide rails 2 are provided with more than two sets, all parallel to each other, The guide rail 2 is slidably connected with a splint, the splint is arranged in a direction perpendicular to the rail 2 and crosses all the rails 2;

[0034] The splint includes a first splint 4 and a second splint 3 that are parallel to each other. The first splint 4 and the second splint 3 are connected by a spring 5, and the springs 5 are parallel to the guide rail 2;

[0035] A magnet 8 is also fixed on the worktable 1, and the magnet is located at one end of the boar...

Embodiment 2

[0039] Figure 1 to Figure 4 Shows a height-adjustable PCB board clamping device provided by this embodiment, which includes a workbench 1, a guide rail 2, a clamping plate, and a board exit channel 6, wherein,

[0040] The guide rail 2 is fixed on the workbench 1. One end of the guide rail 2 is provided with a placement machine 9, and the board exit channel 6 is provided on the workbench 1 below the other end of the guide rail 2. The guide rails 2 are provided with more than two sets, all parallel to each other, The guide rail 2 is slidably connected with a splint, the splint is arranged in a direction perpendicular to the rail 2 and crosses all the rails 2;

[0041] The splint includes a first splint 4 and a second splint 3 that are parallel to each other. The first splint 4 and the second splint 3 are connected by a spring 5, and the springs 5 are parallel to the guide rail 2;

[0042] A magnet 8 is also fixed on the worktable 1, and the magnet is located at one end of the boar...

Embodiment 3

[0047] Figure 1 to Figure 4 Shows a height-adjustable PCB board clamping device provided by this embodiment, which includes a workbench 1, a guide rail 2, a clamping plate, and a board exit channel 6, wherein,

[0048] The guide rail 2 is fixed on the workbench 1. One end of the guide rail 2 is provided with a placement machine 9, and the board exit channel 6 is provided on the workbench 1 below the other end of the guide rail 2. The guide rails 2 are provided with more than two sets, all parallel to each other, The guide rail 2 is slidably connected with a splint, the splint is arranged in a direction perpendicular to the rail 2 and crosses all the rails 2;

[0049] The splint includes a first splint 4 and a second splint 3 that are parallel to each other. The first splint 4 and the second splint 3 are connected by a spring 5, and the springs 5 are parallel to the guide rail 2;

[0050] A magnet 8 is also fixed on the worktable 1, and the magnet is located at one end of the boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com