Automatic discharging device

A technology of automatic feeding and vibrating device, applied in vibrating conveyor, transportation and packaging, sugarcane machining and other directions, can solve the problems of low labor efficiency and labor consumption, and achieve the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

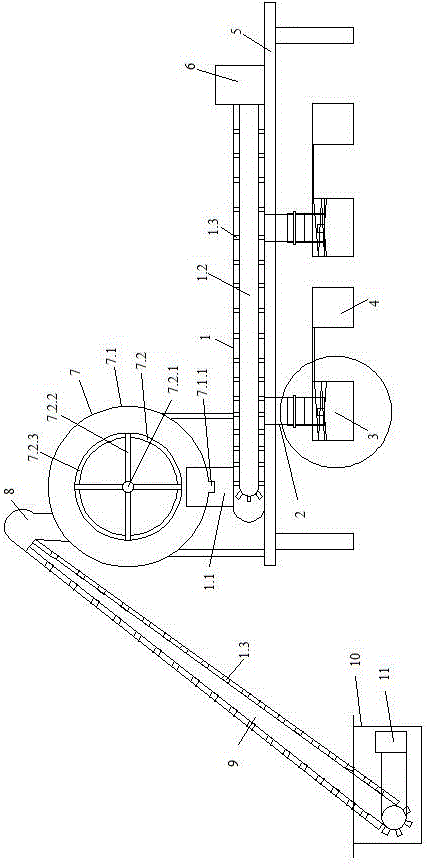

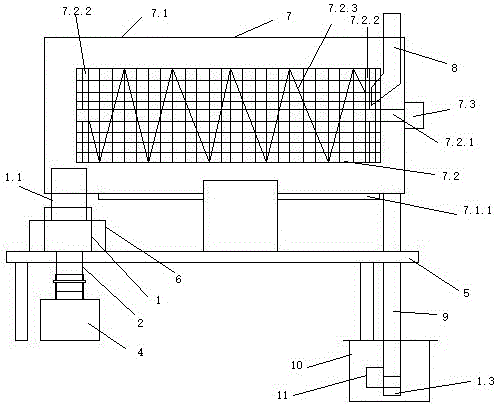

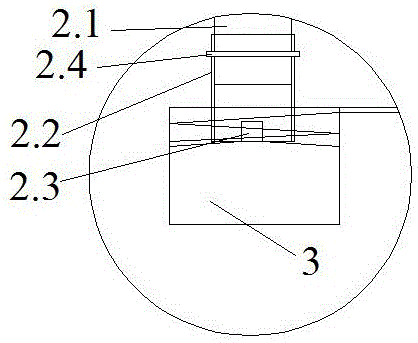

[0017] exist figure 1 and figure 2 Among them, this automatic unloading device includes a second transportation device 1, which is characterized in that there is a feeding pipe 2 under the second transportation device 1, and the bamboo chips are fed through the feeding pipe 2, and the bottom edge of the feeding pipe 2 is in contact with the static When the vibrating device 3 is in contact with the surface of the container, the bottom edge of the feeding tube 2 is provided with a side outlet 2.3.

[0018] exist figure 1 neutralize image 3 Among them, the width of the side outlet 2.3 is 12.5cm, and the height of the side outlet 2.3 is 25cm.

[0019] exist figure 1 Among them, the vibrating device 3 is a vertical circular vibrating machine, and the vibrating device 3 is connected with a bamboo sheet punching device 4 .

[0020] exist image 3 Among them, the blanking pipe 2 is divided into an upper blanking tube 2.1 and a lower blanking tube 2.2; the upper blanking tube 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com