Conic four-piece reciprocating pin scewrod extruder

A technology of screw extruder and conical screw, which is applied in the field of extrusion molding equipment manufacturing, can solve the problems of small compression ratio and volume ratio, decreased fluidity, and reduced delivery volume, so as to achieve stable flow state, high frictional heat, The effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

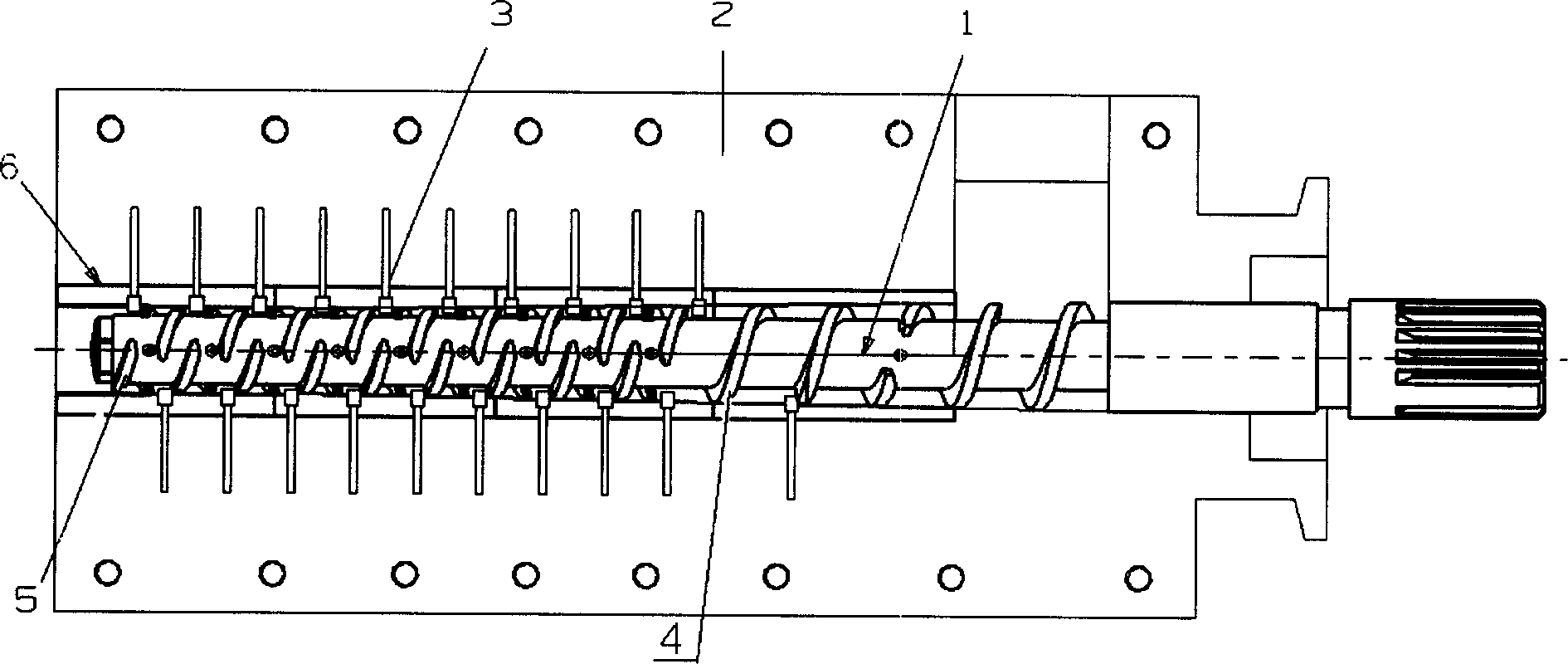

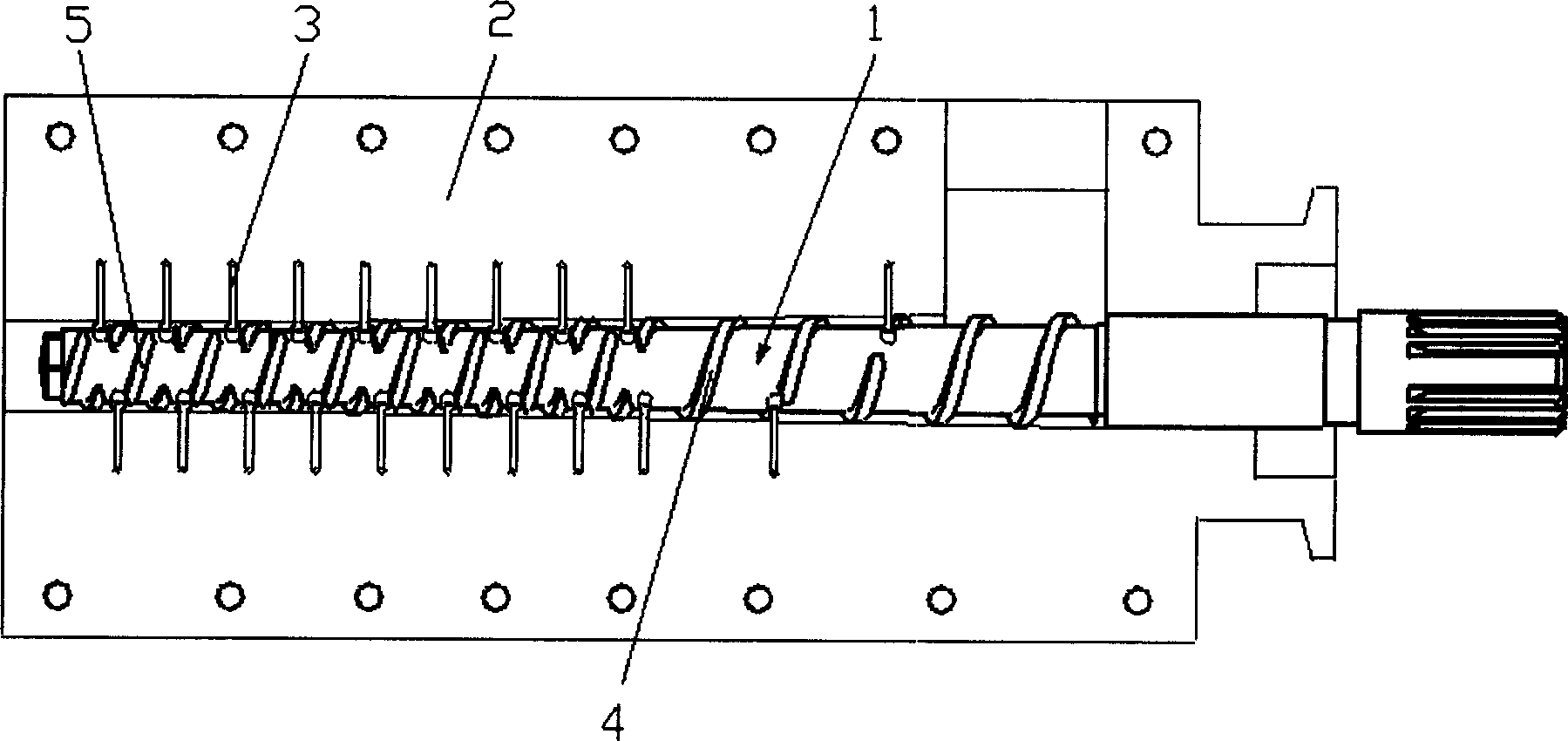

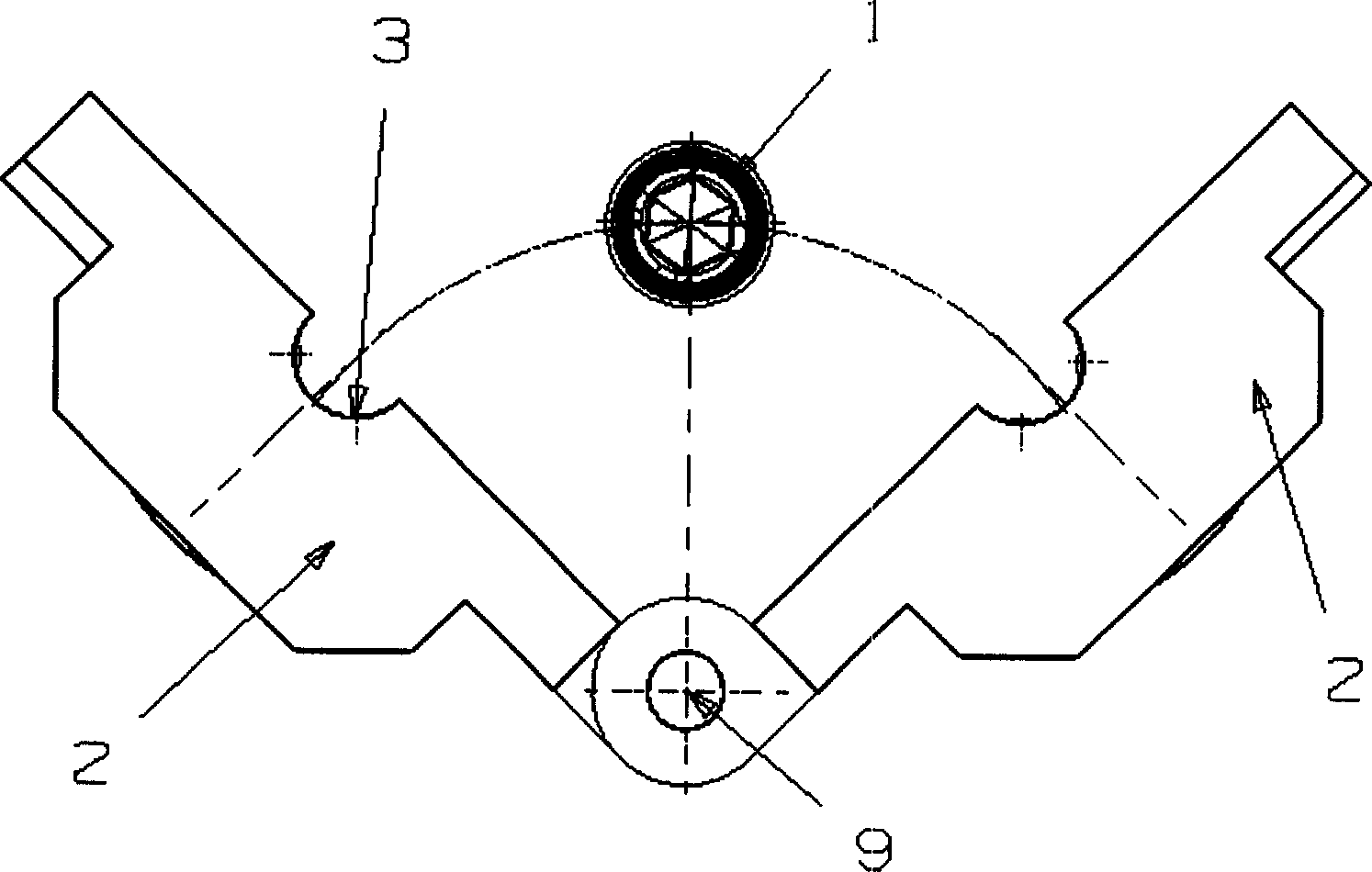

[0030] Such as Figure 1-5 , an extrusion system of a conical four-screw reciprocating screw extruder, including a screw 1, a barrel 2 and a pin 3, the screw 1 is installed in the barrel 2, and consists of a front extrusion section, a middle mixing section and The rear feeding section is composed of the helix protruding from the surface of the screw 1 and having a certain thickness. That section of spiral flight that has interval is spiral sheet. The pin 3 is installed on the inner surface of the barrel 2 opposite to the flight on the screw; the flight 4 is periodically divided into four spiral sheets 5 arranged in a staggered manner along the circumferential helix angle, and the middle of every two flight sheets 5 The gap is used as the pin 3 channel, and the screw pieces 5 are arranged in a staggered front and back, distributed like a "maze", which fundamentally improves the return of the penetrating gap of the "one-shaped" structure where the three screw pieces are interru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com