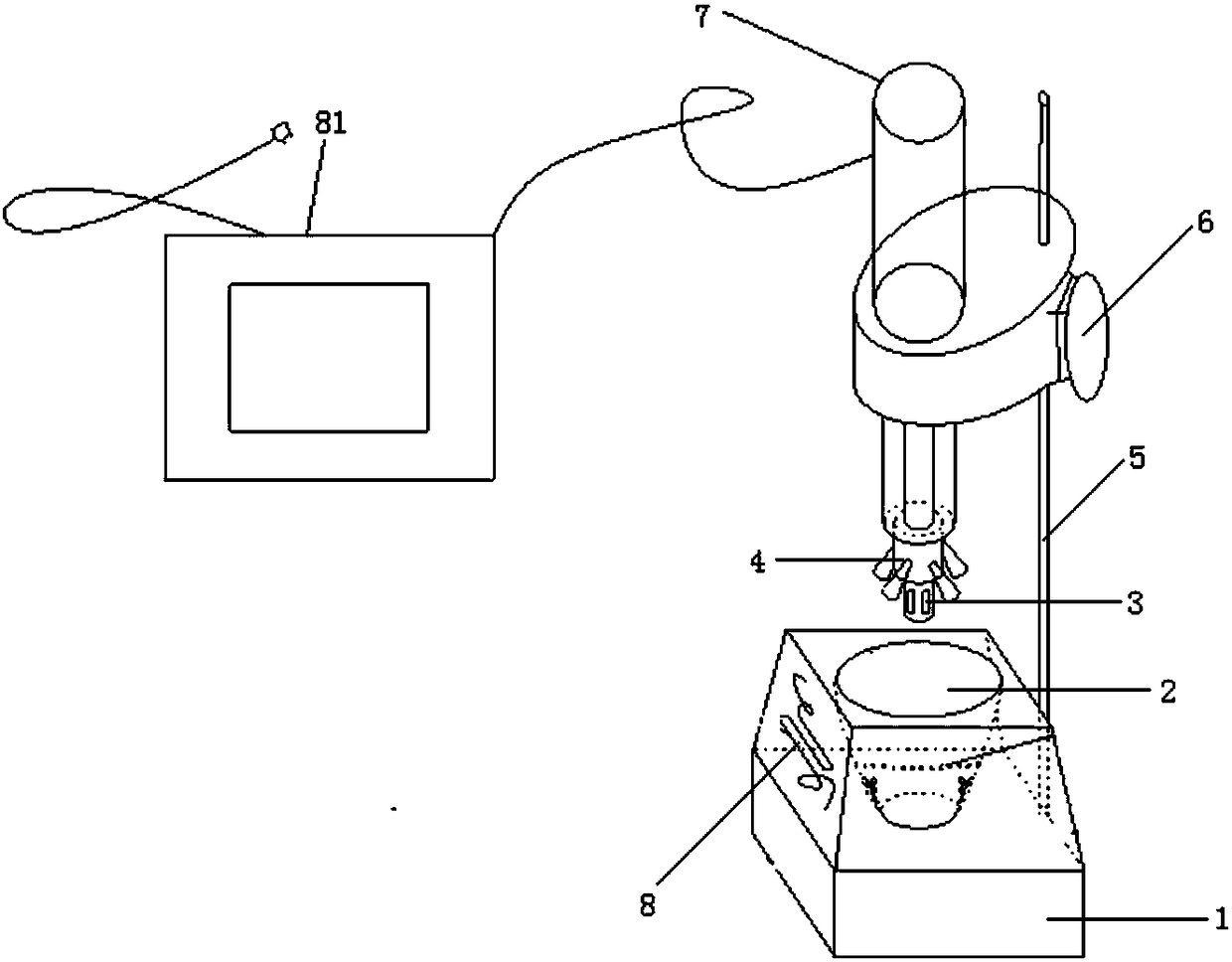

Laboratory high-shear dispersion and emulsion machine

A high-shear and emulsifier technology, applied in the direction of mixers, mixer accessories, chemical instruments and methods, etc., can solve the problems of small shear range and uneven mixing, and achieve uniform shearing, better effect and uniform mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The working process of a laboratory high-shear dispersing and emulsifying machine provided by the present invention is as follows. Use the stirring part installation frame 6 to adjust the stirring part to a suitable position, make it penetrate into the material container 2, and start working when it is powered on.

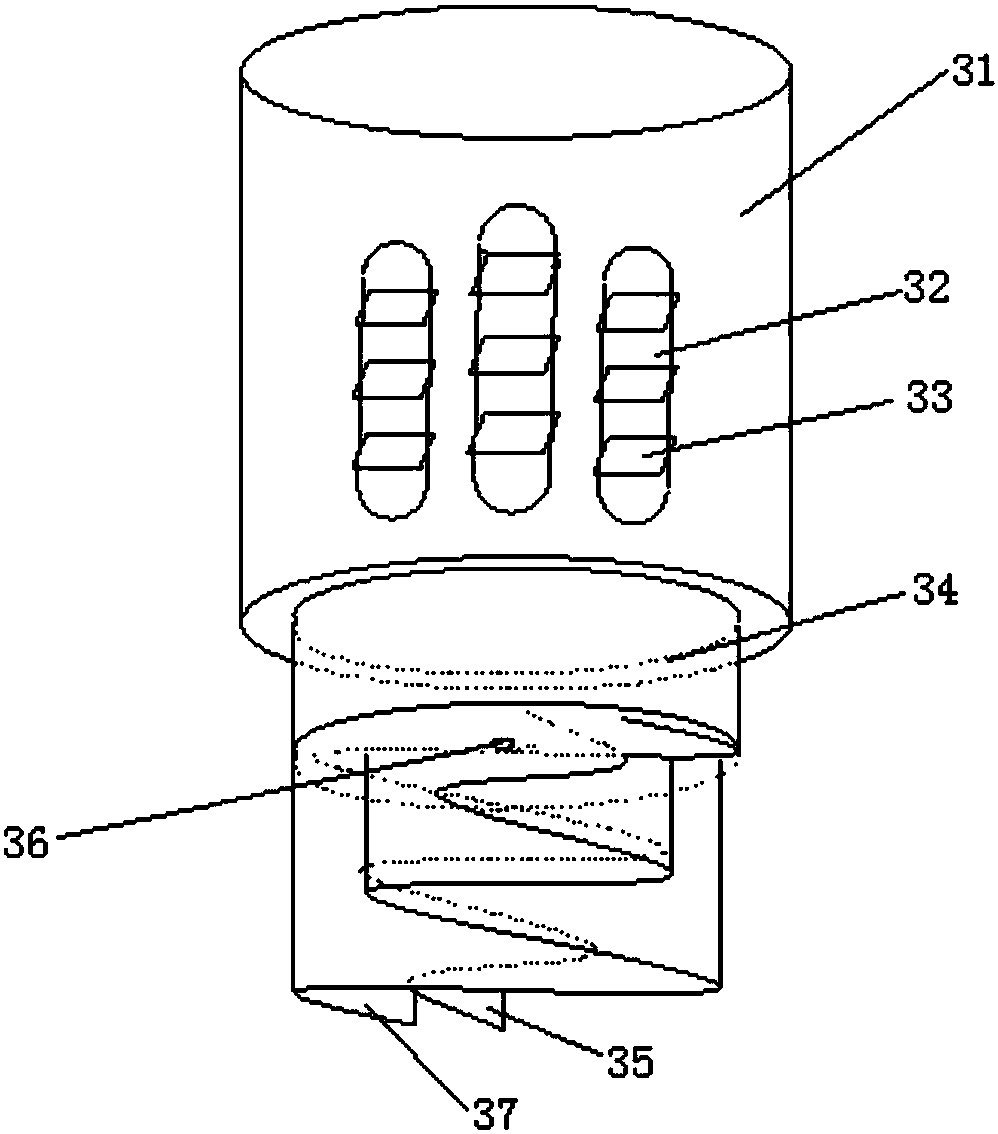

[0067] Such as Figure 13 As shown, during the rotation process, the rotor 38 inside the stator 31 will generate an upward attraction to the material below the stator, so as to promote the circulation of the material below to the upper part. The movement process is specifically: The material flows to the central hole 36 through the material channel formed by the first shearing piece 35 of the first stirring part 3 and the bottom of the connecting cylinder 34, and the material at the bottom of the material container 2 passes through the material channel formed by the second shearing piece 37 and the bottom of the connecting cylinder 34. The material channel f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com