Sectional spiral auger testing platform

A screw auger and test bench technology, applied to cutting equipment, agricultural machinery and tools, applications, etc., can solve the problems of low forage processing efficiency, large forage chopped particle size, and low knot breaking rate, and achieve work efficiency High, increased shear and kneading time, long contact time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

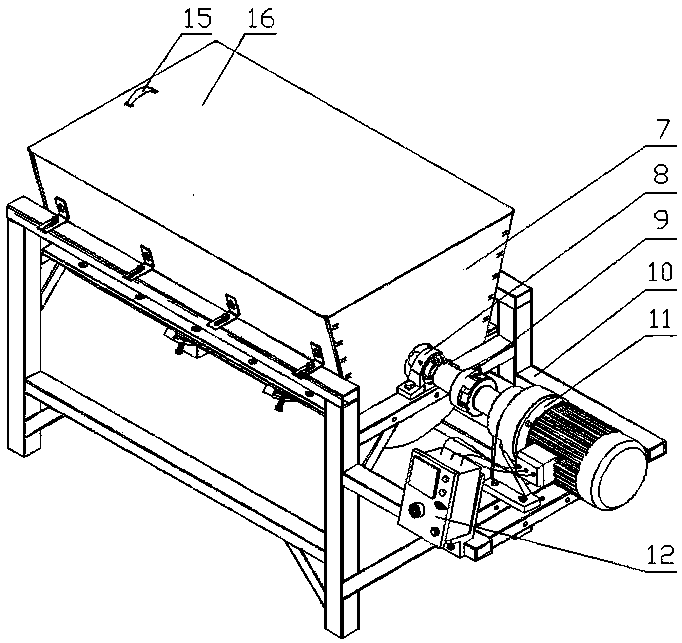

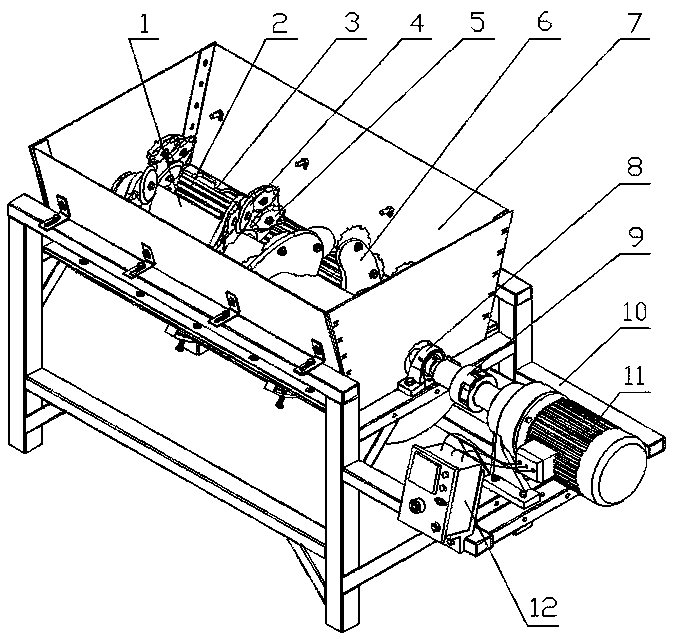

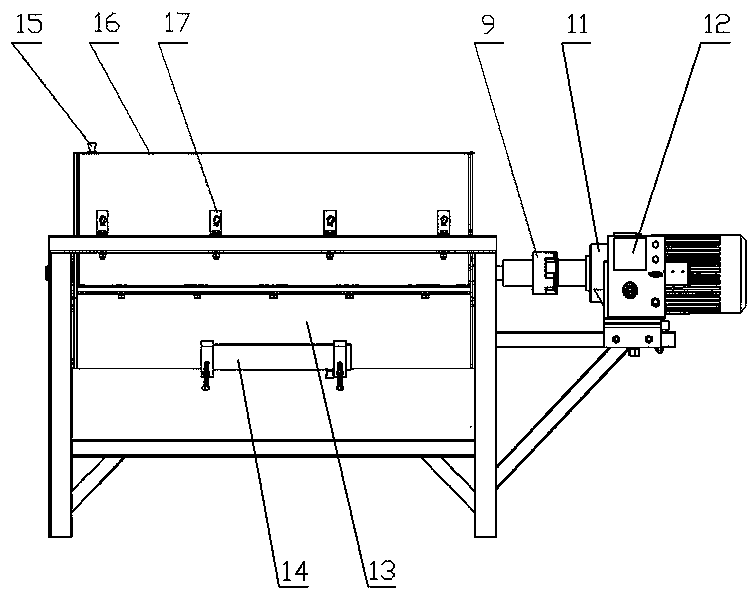

[0013] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing: Figure 1~5 The specific structure of the present invention will be described in detail. As shown in the figure, a segmented screw auger test bench includes an auger shaft tube 1, 10 helical blades 6 are welded on the surface of the auger shaft tube 1, and each helical blade 6 has three holes. Bolts and hexagonal nuts fix two plum-shaped blades 5 and one round blade 4 respectively. The 10 helical blades 6 are relatively distributed on the surface of the auger shaft tube 1 along a single helical line, and 5 helical blades 6 are uniformly and relatively distributed on the helical line at the same interval.

[0014] During the working process of the present invention, place it horizontally, cooperate with the bearing through the auger shaft 11, and connect the coupling 9 through the auger shaft 11, and the coupling 9 is connected with the motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com