Shear friction test device for pressure-bearing granular medium under vibration condition

A particle medium and testing device technology, which is applied to measuring devices, mechanical devices, instruments, etc., can solve calculation errors, force transmission characteristics of pressurized particulate matter, and detection of shear friction force. Effective test methods have not yet been obtained, etc. problem, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

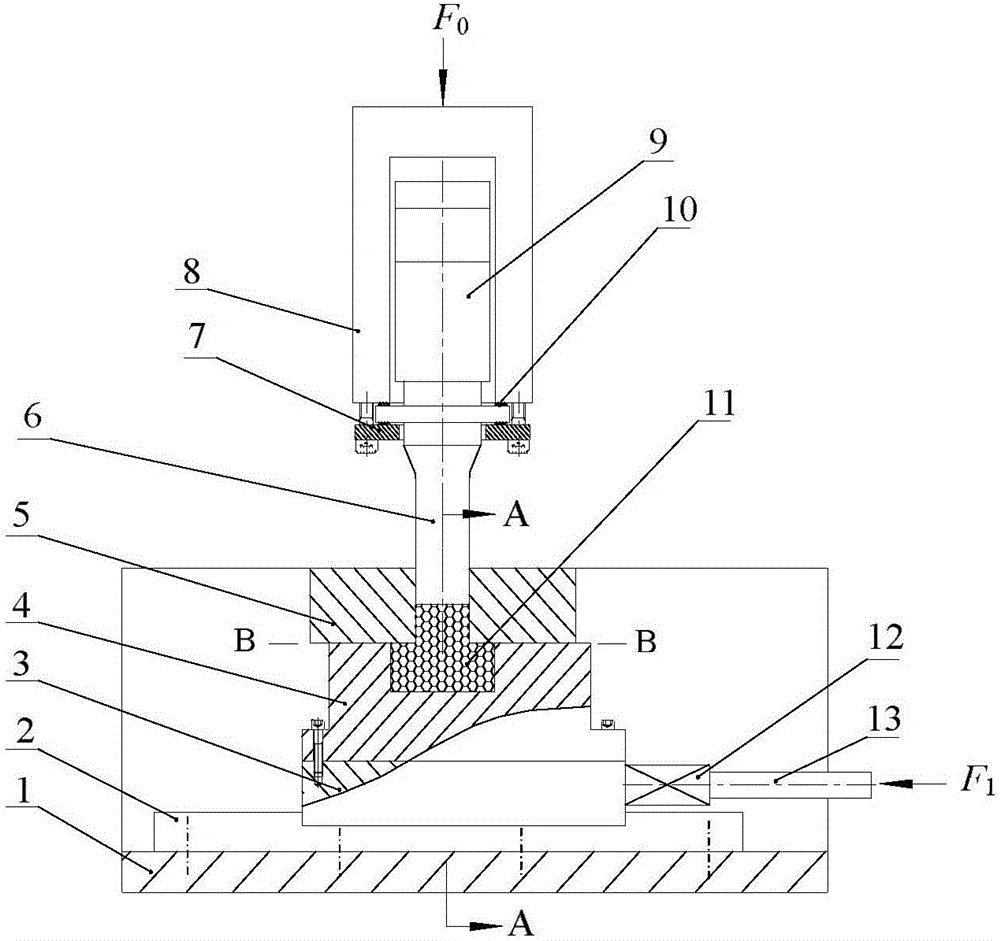

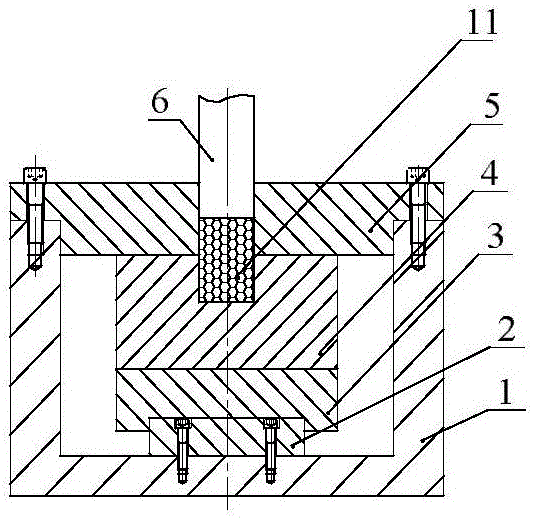

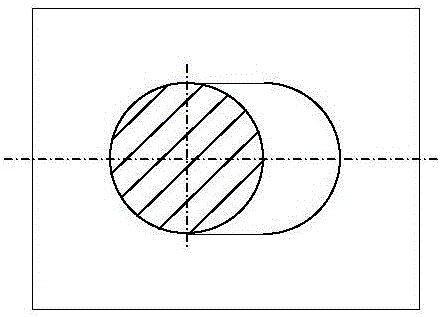

[0032] This embodiment provides a device for testing the shear friction of pressure-bearing granular media under vibration conditions, such as Figure 1-5 As shown, the experimental box 1 is a groove-shaped experimental box, the top of the experimental box 1 is fixed with a fixed box 5 by bolts, and the middle part of the fixed box 5 is provided with a circular through hole with a diameter of 20 mm. The gap is 0.1 mm to ensure that the granular medium 11 will not overflow from the gap when the pressure is applied; the bottom of the experiment box 1 is fixed with a guide rail 2 through bolt connection, and the upper end of the guide rail 2 is provided with a slider 3 that can slide along the guide rail 2. 3. A shearing box 4 is fixed on the upper end by bolts. The middle part of the top of the shearing box 4 is processed with a long slot with a width of 20 mm and a length of 35 mm. The slot depth is 20 mm. The fixed box 5 is assembled with the shearing box 4 Finally, the elonga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com