Polyethylene color master batch and preparation method thereof

A technology of color masterbatch and polyethylene, which is applied in the field of polyethylene color masterbatch and its preparation, can solve the problems of polyethylene color masterbatch that have not been seen yet, and achieve the advantages of reduced shear friction coefficient, stable color and low calorific value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

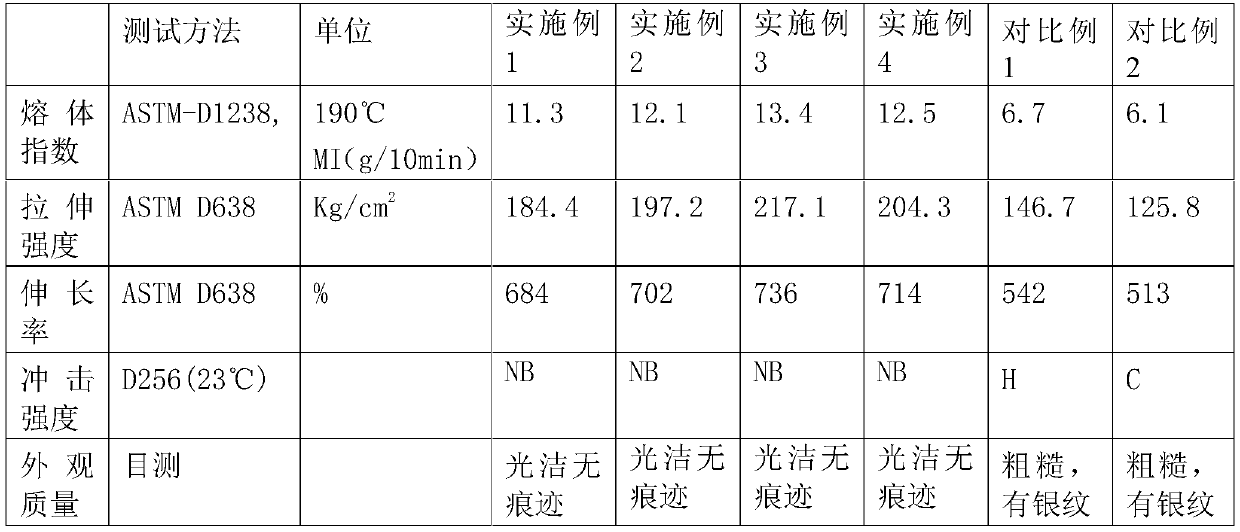

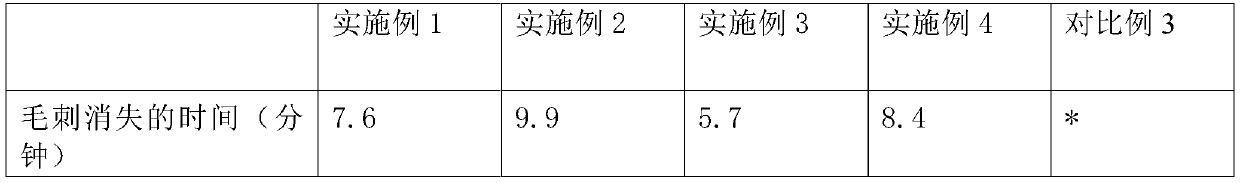

Examples

Embodiment 1

[0025] A polyethylene color masterbatch, comprising the following components by weight: 120 parts of high-density polyethylene, 31 parts of ethylene-ethyl acrylate copolymer, 3 parts of sodium dibutylnaphthalene sulfonate, 2-heptadecyl imidazole 7 parts, 18 parts of white oil, 9 parts of dispersant, 0.7 parts of stabilizer;

[0026] Further, the dispersant is in parts by weight: 4 parts of sodium pyrrolidone carboxylate, 6 parts of methyl N-methyl-2-pyrrole acetate;

[0027] Further, the stabilizer is in parts by weight: 7 parts of tridecyl trimellitate, 6 parts of barium stearate;

[0028] The preparation method of above-mentioned a kind of polyethylene color masterbatch is:

[0029] (1) Weigh high-density polyethylene, ethylene-ethyl acrylate copolymer, sodium dibutylnaphthalene sulfonate, 2-heptadecyl imidazole, and white oil, and add them to a three-bladed mixer, and the mixing condition is at a temperature of 83°C Mix for 0.5 hours, mix well;

[0030] (2) Mix the produ...

Embodiment 2

[0033] A polyethylene color masterbatch, comprising the following components by weight: 185 parts of high-density polyethylene, 17 parts of ethylene-ethyl acrylate copolymer, 4 parts of sodium dibutylnaphthalene sulfonate, 2-heptadecyl imidazole 7 parts, white oil 16 parts, dispersant 2 parts, stabilizer 4 parts;

[0034] Further, the dispersant is in parts by weight: 7 parts of sodium pyrrolidone carboxylate, 4 parts of methyl N-methyl-2-pyrrole acetate;

[0035] Further, the stabilizer is in parts by weight: 18 parts of tridecyl trimellitate, 27 parts of barium stearate;

[0036] The preparation method of above-mentioned a kind of polyethylene color masterbatch is:

[0037] (1) Weigh high-density polyethylene, ethylene-ethyl acrylate copolymer, sodium dibutylnaphthalene sulfonate, 2-heptadecyl imidazole, and white oil, and add them to a three-bladed mixer, and the mixing condition is at 72°C Mix for 1 hour, mix well;

[0038] (2) Mix the product and toner in step 1 in a h...

Embodiment 3

[0041] A polyethylene color masterbatch, comprising the following components by weight: 150 parts of high-density polyethylene, 20 parts of ethylene-ethyl acrylate copolymer, 8 parts of sodium dibutyl naphthalene sulfonate, 2-heptadecyl imidazole 5 parts, 23 parts of white oil, 6 parts of dispersant, 4 parts of stabilizer;

[0042] Further, the dispersant is in parts by weight: 5 parts of sodium pyrrolidone carboxylate, 6 parts of methyl N-methyl-2-pyrrole acetate;

[0043] Further, the stabilizer is in parts by weight: 13 parts of tridecyl trimellitate, 18 parts of barium stearate;

[0044] The preparation method of above-mentioned a kind of polyethylene color masterbatch is:

[0045] (1) Weigh high-density polyethylene, ethylene-ethyl acrylate copolymer, sodium dibutylnaphthalene sulfonate, 2-heptadecyl imidazole, and white oil, and add them to a three-blade mixer, and the mixing condition is at a temperature of 78°C Mix for 0.8 hours, mix well;

[0046](2) Mix the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com