Non-fried instant dough sheets and high-temperature extruding-puffing production technology thereof

A non-fried instant noodle and flour technology, which is applied in the direction of baking method, pre-baked dough treatment, baking, etc., can solve the problems such as not being able to meet the requirements, and achieve the effects of benefiting health, improving rehydration, improving chewiness and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

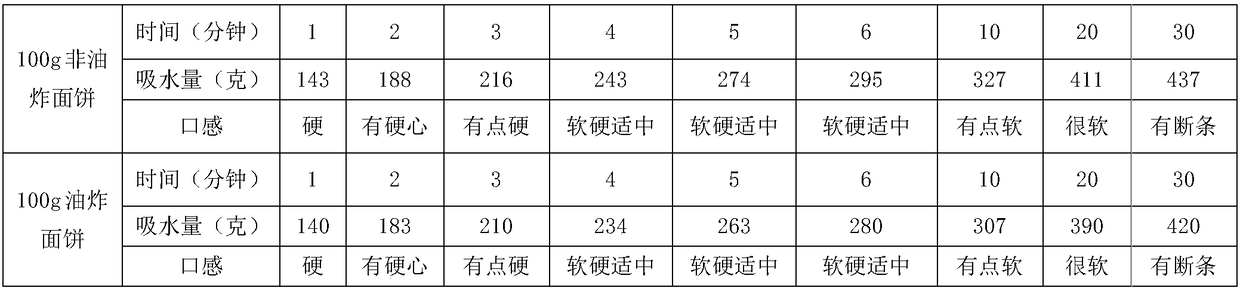

Image

Examples

Embodiment 1

[0017] A non-fried instant noodle skin, which comprises the following raw materials in parts by weight: 20 parts of flour, 0.08 part of potato starch, 0.1 part of gluten powder, 0.08 part of table salt, 0.03 part of vegetable oil and 6 parts of clear water.

[0018] A kind of extrusion, high-temperature puffing production process of above-mentioned non-fried instant noodles, comprises the following steps:

[0019] a. Put 20 parts of wheat flour, 0.08 parts of potato starch and 0.1 part of gluten powder into the dough mixer, and dry mixing time is 1 minute;

[0020] b. Pour 0.08 parts of salt, 0.03 parts of vegetable oil, and 6 parts of water into the container and stir for later use;

[0021] C. After the dry stirring in step a is finished, pour the prepared saline solution evenly into the dough mixer and stir for 2 minutes. In summer, ripen for 5 minutes and set aside;

[0022] c. After the dry stirring in step a is finished, pour the prepared saline solution evenly into the...

Embodiment 2

[0031] A non-fried instant noodle skin comprises the following raw materials in parts by weight: 25 parts of flour, 1 part of potato starch, 0.15 part of gluten powder, 0.1 part of table salt, 0.05 part of vegetable oil and 7.5 parts of clear water.

[0032] A kind of extrusion, high-temperature puffing production process of above-mentioned non-fried instant noodles, comprises the following steps:

[0033] a. Put 25 parts of wheat flour, 0.1 part of potato starch, and 0.15 parts of gluten powder into the dough mixer, and dry mixing time is 2 minutes;

[0034] b. 0.1 part of salt, 0.05 part of vegetable oil, and 7.5 parts of water are poured into the container and stirred for later use;

[0035] c. After the dry mixing in step a is finished, pour the prepared saline solution evenly into the dough mixer and stir for 2.5 minutes. In spring and autumn, ripen at room temperature for 8 minutes and then set aside;

[0036] d. Take the cooked dough, put it into the hopper of the bean...

Embodiment 3

[0040] A non-fried instant noodle skin comprises the following raw materials in parts by weight: 30 parts of flour, 0.12 parts of potato starch, 0.2 parts of gluten powder, 0.12 parts of table salt, 0.07 parts of vegetable oil and 8 parts of clear water.

[0041] A kind of extrusion, high-temperature puffing production process of above-mentioned non-fried instant noodles, comprises the following steps:

[0042] a. Put 30 parts of wheat flour, 0.12 parts of potato starch, and 0.2 parts of gluten flour into the dough mixer, and dry mixing time is 5 minutes;

[0043] b. 0.12 parts of salt, 0.07 parts of vegetable oil, and 8 parts of water are poured into the container and stirred for later use;

[0044] c. After the dry mixing in step a is finished, pour the prepared saline solution evenly into the dough mixer and stir for 3 minutes. In winter, ripen for 10 minutes at room temperature at room temperature for later use;

[0045] d. Take the cooked dough, put it into the hopper of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com