Boiling detection method and device

A detection method and a technology of a detection device, which are applied to measuring devices, heat measurement, and temperature measurement of moving fluids, etc., can solve problems such as high manufacturing costs, weak adaptability to different altitudes, and poor user experience, and achieve cost reduction, Improve the effect of user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

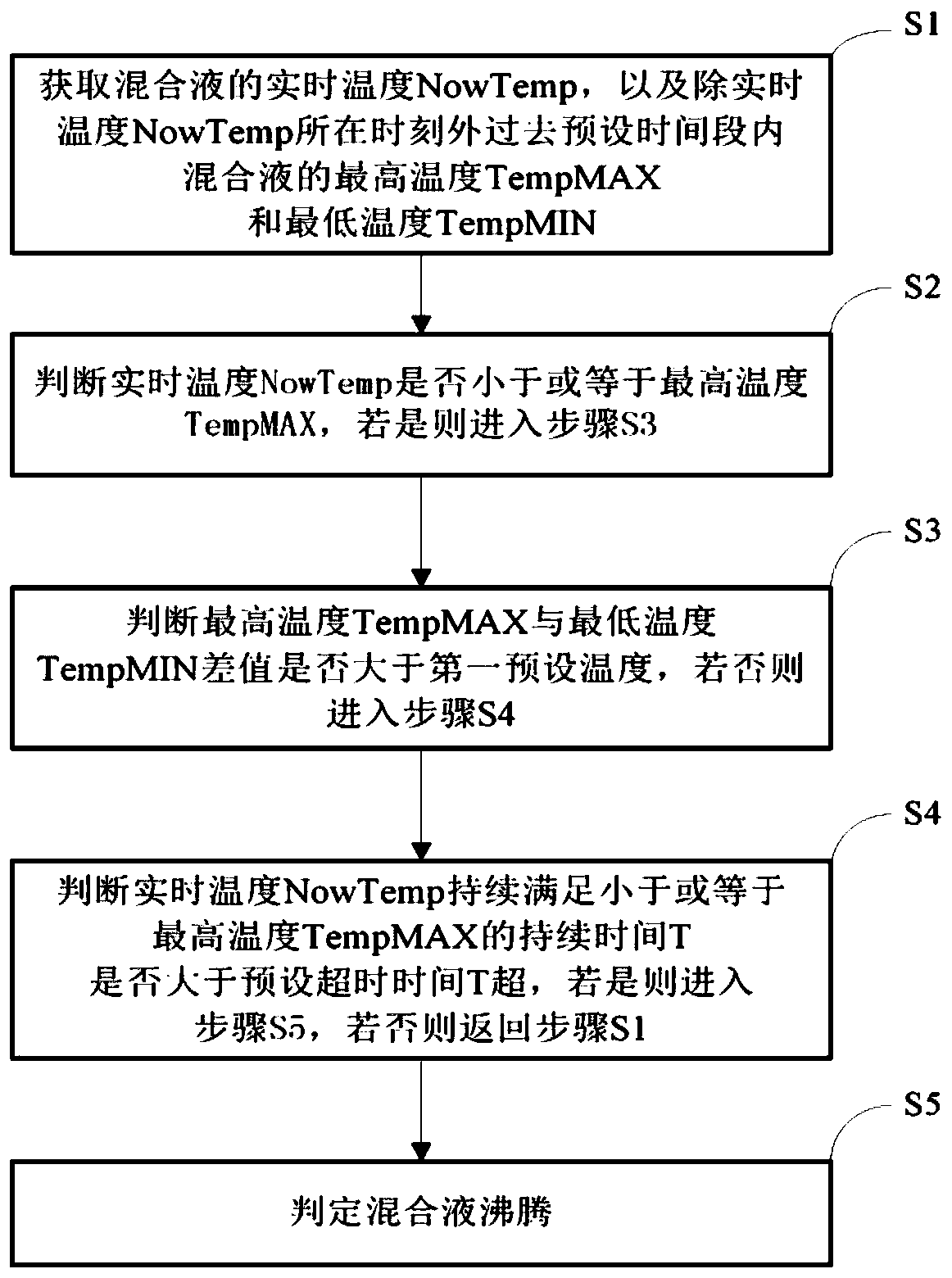

Method used

Image

Examples

Embodiment 2

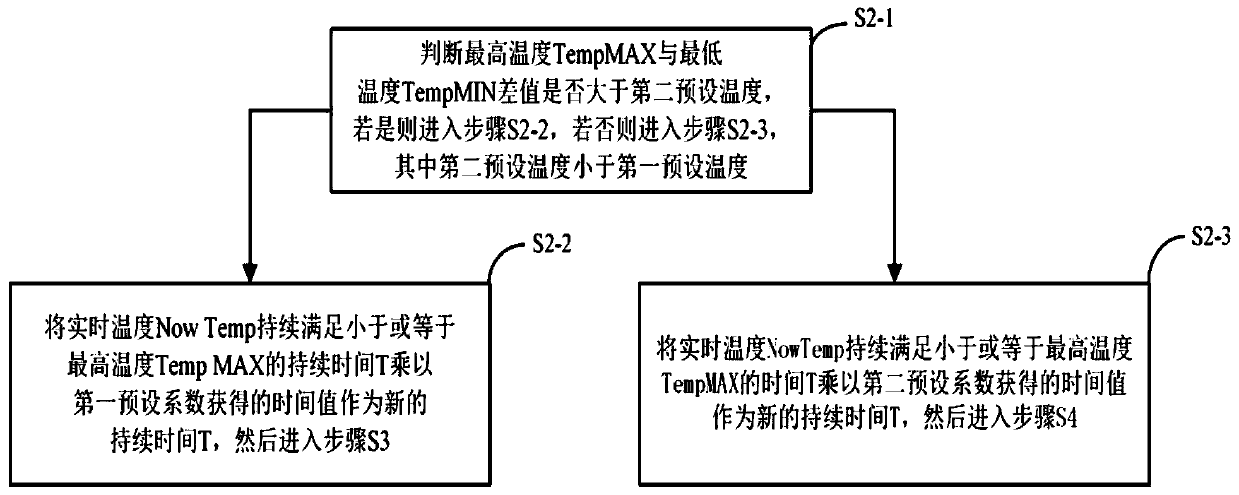

[0061] Embodiment 2 is based on the boiling detection method provided in Embodiment 1 and further includes: if in step S2 of the boiling detection method provided in Embodiment 1, if the judgment result is otherwise, enter step S2-1:

[0062] Wherein step S2-1 is: determine whether the difference between the highest temperature TempMAX and the lowest temperature TempMIN is greater than the second preset temperature, if so, enter step S2-2, otherwise enter step S2-3, wherein the second preset temperature is less than the first preset temperature;

[0063] Optionally, the second preset temperature is 1°C.

[0064] It can be understood that if the real-time temperature NowTemp of the mixture at the Kth moment is obtained, and the preset time period is 30 seconds, then the maximum temperature TempMAX and the minimum temperature TempMIN are the highest temperature TempMAX and the minimum temperature of the mixture in the past 30 seconds from the K-1 moment. Temperature TempMIN. E...

Embodiment 3

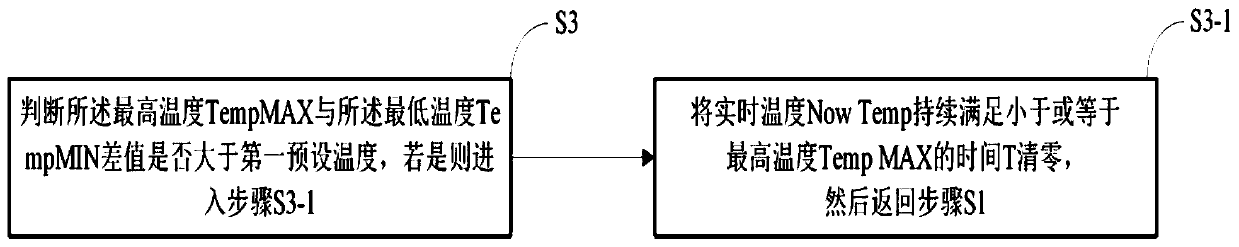

[0071] Embodiment 3 is based on the boiling detection method provided in Embodiment 1 or Embodiment 2, and further includes: if the judgment result in step S3 is yes, then enter step S3-1,

[0072] S3-1: Clear the time T during which the real-time temperature Now Temp is less than or equal to the maximum temperature Temp MAX to zero, and then return to step S1.

[0073] It can be understood that if the difference between the highest temperature TempMAX and the lowest temperature TempMIN within the collected preset time is too large, that is, greater than the first preset temperature, it means that the discrete value of the collected real-time temperature data is too large and cannot be used to judge the mixed temperature. The liquid is boiling, so it is necessary to reset the continuous satisfaction time T to zero and collect again.

Embodiment 4

[0075] Embodiment 4 is based on the boiling detection method provided in Embodiment 1 or Embodiment 2 or Embodiment 3. It also includes: before the step S1, it also includes:

[0076] S1-1: Start heating at full power and stir evenly, and detect the real-time temperature NowTemp of the mixture;

[0077] S1-2: Determine whether the real-time temperature NowTemp is greater than or equal to the preset temperature threshold, if so, enter step S1-3, otherwise return to step S1-1;

[0078] S1-3: Switch to half-power heating, and then enter step S1.

[0079] Further, the preset temperature threshold is the boiling temperature of water at a preset altitude.

[0080] Stirring and shaking during the heating process in step S1-1 has two effects: first, it prevents the ingredients from sticking to the bottom; As a result, the temperature in the area close to the heating plate is high and the temperature in the area away from the heating plate is low), until the temperature of all the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com