Raw soybean milk heat exchange rapid boiling method

A technology of raw soybean milk and boiled milk method, applied in the direction of food science, etc., can solve the problems of affecting the purity and concentration of soybean milk, mixing of impurities and impurities, and difficulty in reducing the cost, so as to achieve stable soybean milk quality, consistent soybean milk quality, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

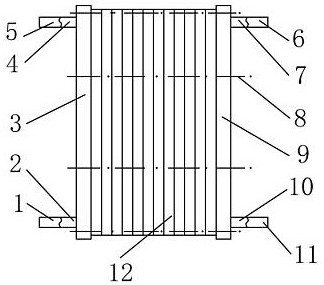

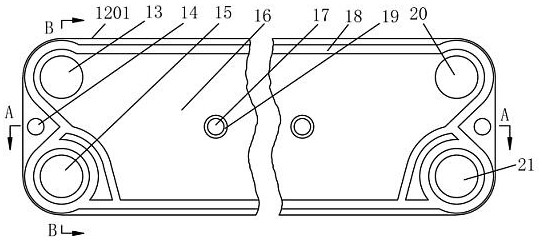

[0027] The equipment of the present invention and the pulp cooking process are further described below with reference to the accompanying drawings.

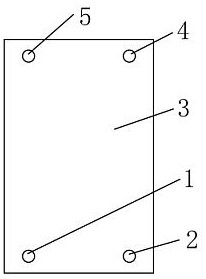

[0028] like figure 1 As shown in -9, the left end plate 3 and the right end plate 9 are rectangular plates. It is made of thicker stainless steel plate so as to be able to withstand large tensile force without deformation. There are corresponding inlets at the four through holes on the four corners of the plates at both ends and the four corners of the heat exchange plate, namely the left inlets 5 and B on the A passage. Upper left entry 4, A lower left entry 1, B lower left entry 2, A right entry 6, B upper right entry 7, A lower right entry 11, and B lower right entry 10. These inlets are made of metal pipes, and are connected with corresponding gate valves or with connecting threads, and there are accessories such as connecting sealing gaskets at the connection with the heat exchange disk to ensure no air leakage.

[0029] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com