Low-rainbow-pattern polyester optical film coating liquid and preparation method thereof

A technology of rainbow pattern and optical film, which is applied in polyester coatings, chemical instruments and methods, polyurea/polyurethane coatings, etc. The effect of rainbow pattern, strong adhesion and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

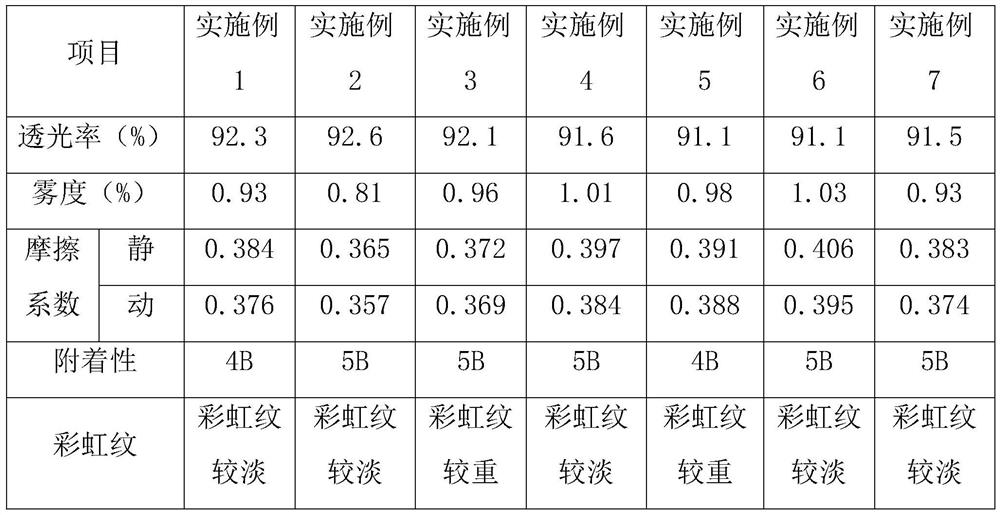

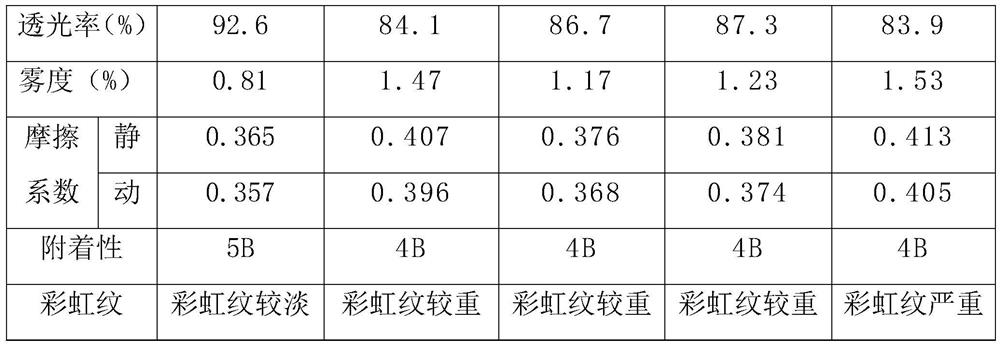

Examples

Embodiment 1

[0043] According to mass percentage, take 10% water-based polyurethane, 30% water-based polyester, 0.4% melamine resin, 0.4% absolute ethanol, 0.1% polyether modified polysiloxane, 0.2% organic fluorocarbon wetting agent, 0.4% %nanoparticles, 58.5% deionized water, standby;

[0044]Take the wetting agent and add absolute ethanol to dilute, then slowly add to deionized water, and stir evenly, wherein the amount of deionized water is 50% of the total water amount required by the formula to prepare solution A; take water-based polyurethane and water-based polyester respectively Slowly add to solution A in a stirring state, keep stirring to make solution B; take melamine resin and add deionized water to dilute, slowly add to solution B, keep stirring to make solution C; take nanoparticles to make aqueous dispersion solution, the content of silicon dioxide in the solution is 40%, add deionized water to dilute, stir evenly, slowly add to solution C in a stirring state, then add deio...

Embodiment 2

[0047] According to mass percentage, take 20% water-based polyurethane, 20% water-based polyester, 0.5% melamine resin, 0.4% absolute ethanol, 0.1% polyether modified polysiloxane, 0.2% organic fluorocarbon wetting agent, 0.5% %nanoparticles, 58.3% deionized water, standby;

[0048] Take the wetting agent and add absolute ethanol to dilute, then slowly add to deionized water, and stir evenly, wherein the amount of deionized water is 65% of the total water amount required by the formula to prepare solution A; take water-based polyurethane and water-based polyester respectively Slowly add to solution A in a stirring state, keep stirring to make solution B; take melamine resin and add deionized water to dilute, slowly add to solution B, keep stirring to make solution C; take nanoparticles to make aqueous dispersion solution, the content of silicon dioxide in the solution is 40%, add deionized water to dilute, stir evenly, slowly add to solution C in a stirring state, then add dei...

Embodiment 3

[0051] According to mass percentage, take 30% water-based polyurethane, 10% water-based polyester, 0.5% melamine resin, 0.5% absolute ethanol, 0.2% polyether modified polysiloxane, 0.2% organic fluorocarbon wetting agent, 0.5% %nanoparticles, 58.1% deionized water, standby;

[0052] Take the wetting agent and add absolute ethanol to dilute, then slowly add to deionized water, and stir evenly, wherein the amount of deionized water is 80% of the total water amount required by the formula to prepare solution A; take water-based polyurethane and water-based polyester respectively Slowly add to solution A in a stirring state, keep stirring to make solution B; take melamine resin and add deionized water to dilute, slowly add to solution B, keep stirring to make solution C; take nanoparticles to make aqueous dispersion solution, the content of silicon dioxide in the solution is 40%, add deionized water to dilute, stir evenly, slowly add to solution C in a stirring state, then add dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com