Traceless stage tooth double-face sharp knife edge tooth scissor

A high-low-tooth, double-sided technology, applied in the field of haircutting equipment, achieves the effect of smooth cross-section, low haircut friction, and good haircut feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

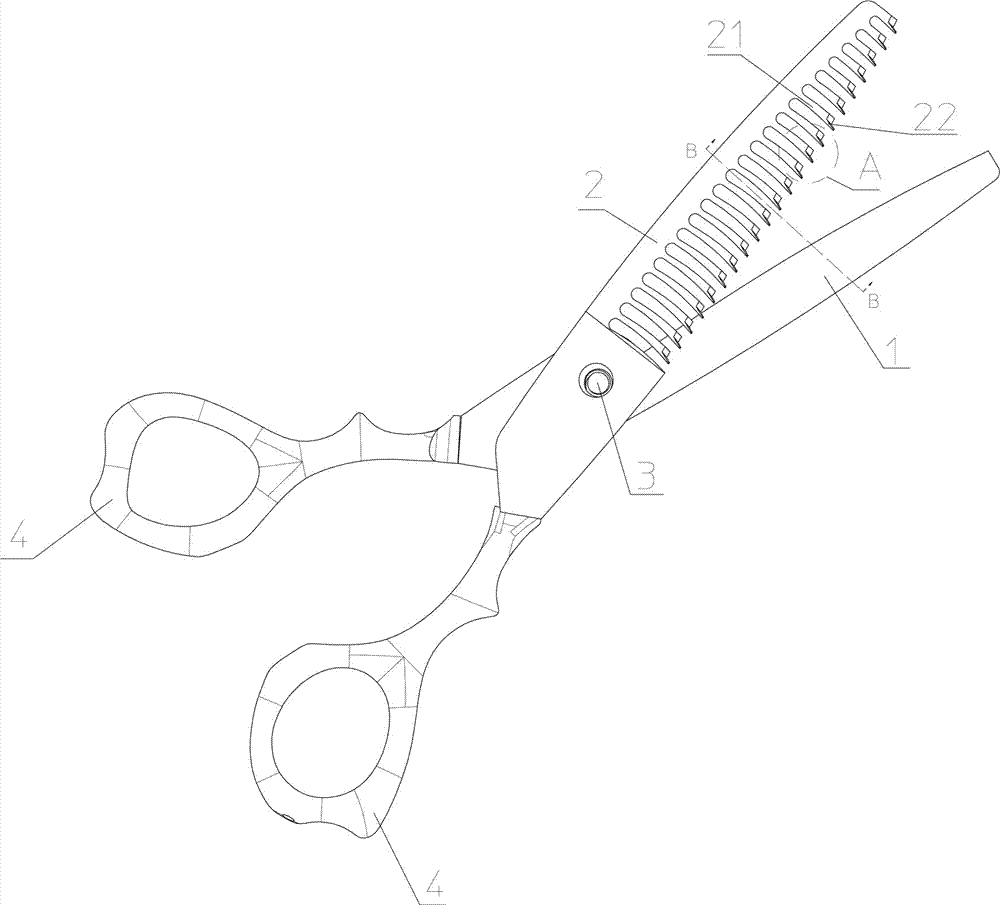

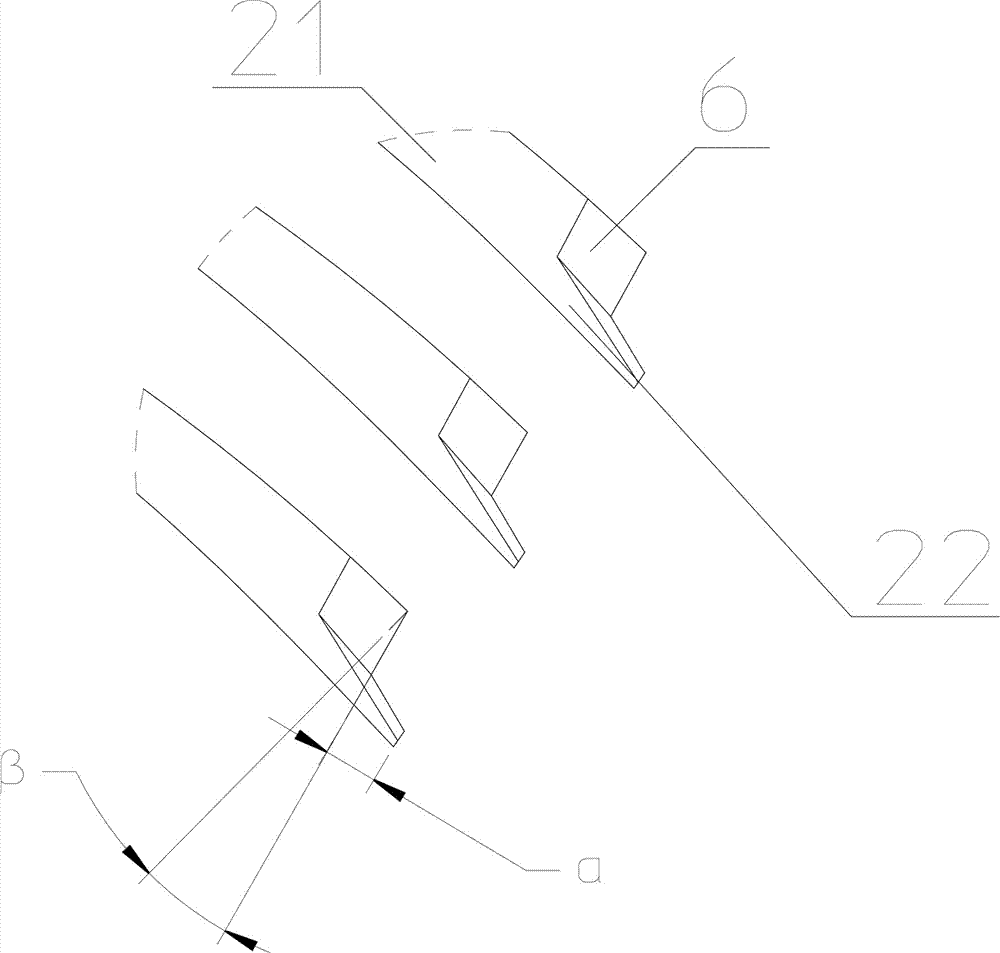

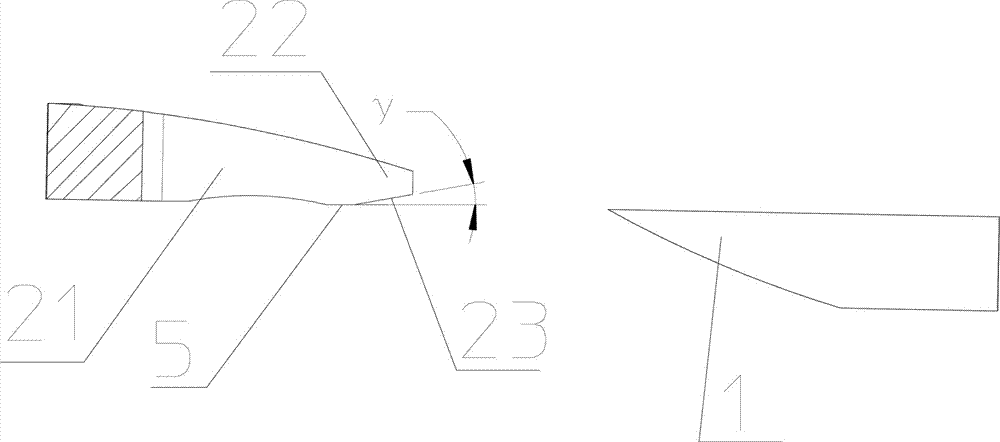

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the non-marking high and low teeth double-sided fast-edged dental scissors include: a moving blade 1 and a static blade 2, the moving blade 1 and the static blade 2 are hinged by a pivot 3, and the moving blade 1 and the static blade The tail ends of the blades 2 are all provided with finger rings 4 for finger-driven blade opening and closing. The blade of the moving blade 1 moves toward the blade of the static blade 2 to cut hair. The tooth edges of the arranged static blade comb teeth 21 are formed. The tooth edges of each static blade comb tooth 21 are formed by the intersection of a horizontal plane 5 and an inclined plane 6. The horizontal planes 5 of the tooth blades of each static blade comb tooth 21 are on the same plane. The cutting edge angle α...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com