a zrb 2 Solidification preparation method of -sic eutectic composite ceramics

A technology of composite ceramics and zrb2-sic, which is applied in the field of ultra-high temperature composite ceramic materials, can solve problems such as inability to reach extremely high temperatures, and achieve the effects of fast heating rate, convenient movement, and uniform phase distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

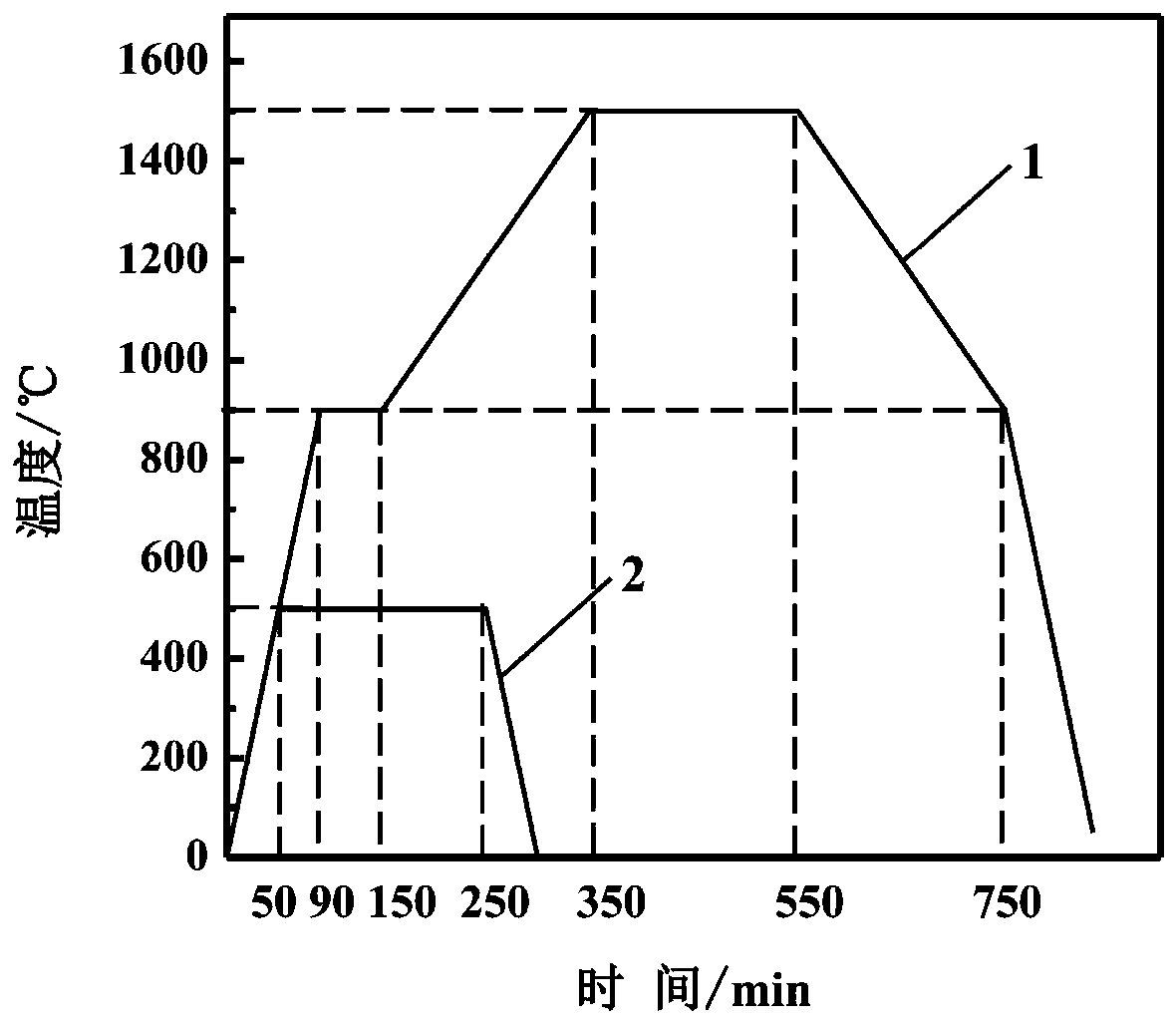

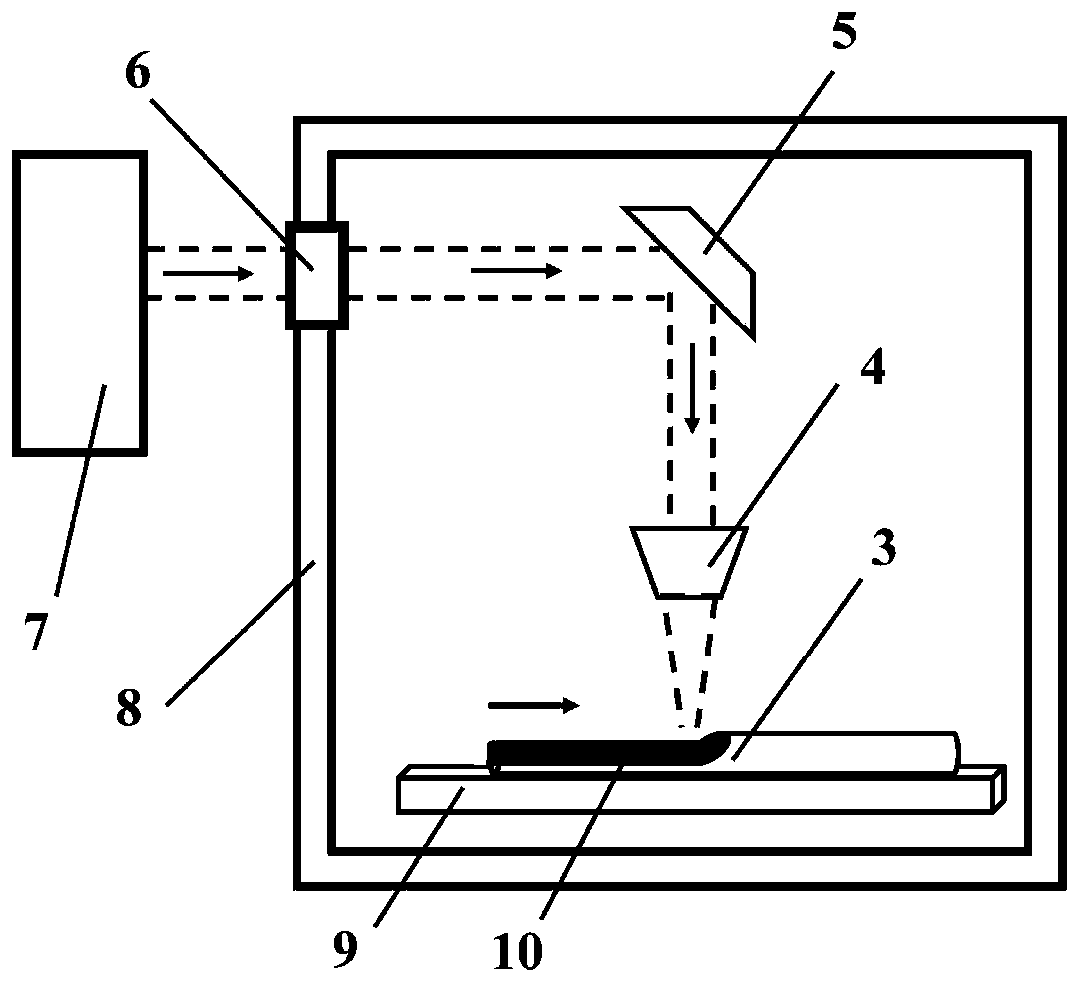

[0040] This embodiment is a ZrB 2 -Directional solidification preparation method of SiC material. In this embodiment, ZrB is prepared by laser horizontal zone melting high-gradient directional solidification technology 2 -SiC eutectic ceramic composite material, the specific process includes the following steps:

[0041] Step 1. Prepare ZrB 2 -SiC eutectic composite ceramic prefabricated powder. Commercially available powdered ZrB with a purity of 99.9% 2 And SiC as raw materials, press ZrB 2 -The eutectic composition of SiC is made into base material raw material; the ZrB 2 -The eutectic composition of SiC is 38.5~44.5mol% ZrB 2 -55.5~61.5mol% SiC; in this embodiment, ZrB 2 It is 38.5 mol% and SiC is 61.5 mol%. 20ml of polyvinyl alcohol binder and 60ml of absolute ethanol are added to every 100g of base material raw materials, manually stirred evenly, and allowed to stand for 5 minutes; the preparation method of the polyvinyl alcohol binder is 100ml of distilled water+5g of poly...

Embodiment 2

[0049] This example is a preparation of high-density ZrB 2 -SiC material method. In this embodiment, ZrB is prepared by laser horizontal zone melting high-gradient directional solidification technology 2 -SiC eutectic ceramic composite material, the specific process includes the following steps:

[0050] This embodiment is a ZrB 2 -Directional solidification preparation method of SiC material. In this embodiment, ZrB is prepared by laser horizontal zone melting high-gradient directional solidification technology 2 -SiC eutectic ceramic composite material, the specific process includes the following steps:

[0051] Step 1. Prepare ZrB 2 -SiC eutectic composite ceramic prefabricated powder. Commercially available powdered ZrB with a purity of 99.9% 2 And SiC as raw materials, press ZrB 2 -The eutectic composition of SiC is made into base material raw material; the ZrB 2 -The eutectic composition of SiC is 38.5~44.5mol% ZrB 2 -55.5~61.5mol% SiC; in this embodiment, ZrB 2 It is 41.5 m...

Embodiment 3

[0059] This embodiment is a ZrB 2 -Directional solidification preparation method of SiC material. In this embodiment, ZrB is prepared by laser horizontal zone melting high-gradient directional solidification technology 2 -SiC eutectic ceramic composite material, the specific process includes the following steps:

[0060] Step 1. Prepare ZrB 2 -SiC eutectic composite ceramic prefabricated powder. Commercially available powdered ZrB with a purity of 99.9% 2 And SiC as raw materials, press ZrB 2 -The eutectic composition of SiC is made into base material raw material; the ZrB 2 -The eutectic composition of SiC is 38.5~44.5mol% ZrB 2 -55.5~61.5mol% SiC; in this embodiment, ZrB 2 It is 44.5 mol% and SiC is 55.5 mol%. 20ml of polyvinyl alcohol binder and 60ml of absolute ethanol are added to every 100g of base material raw materials, manually stirred evenly, and allowed to stand for 5 minutes; the preparation method of the polyvinyl alcohol binder is 100ml of distilled water+5g of poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com