Method for casting hub casts of aerogenerators

A technology for wind turbines and castings, applied in the casting field of castings, can solve the problems of inclusions, easy scouring of molds, easy cracks and shrinkage porosity in castings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

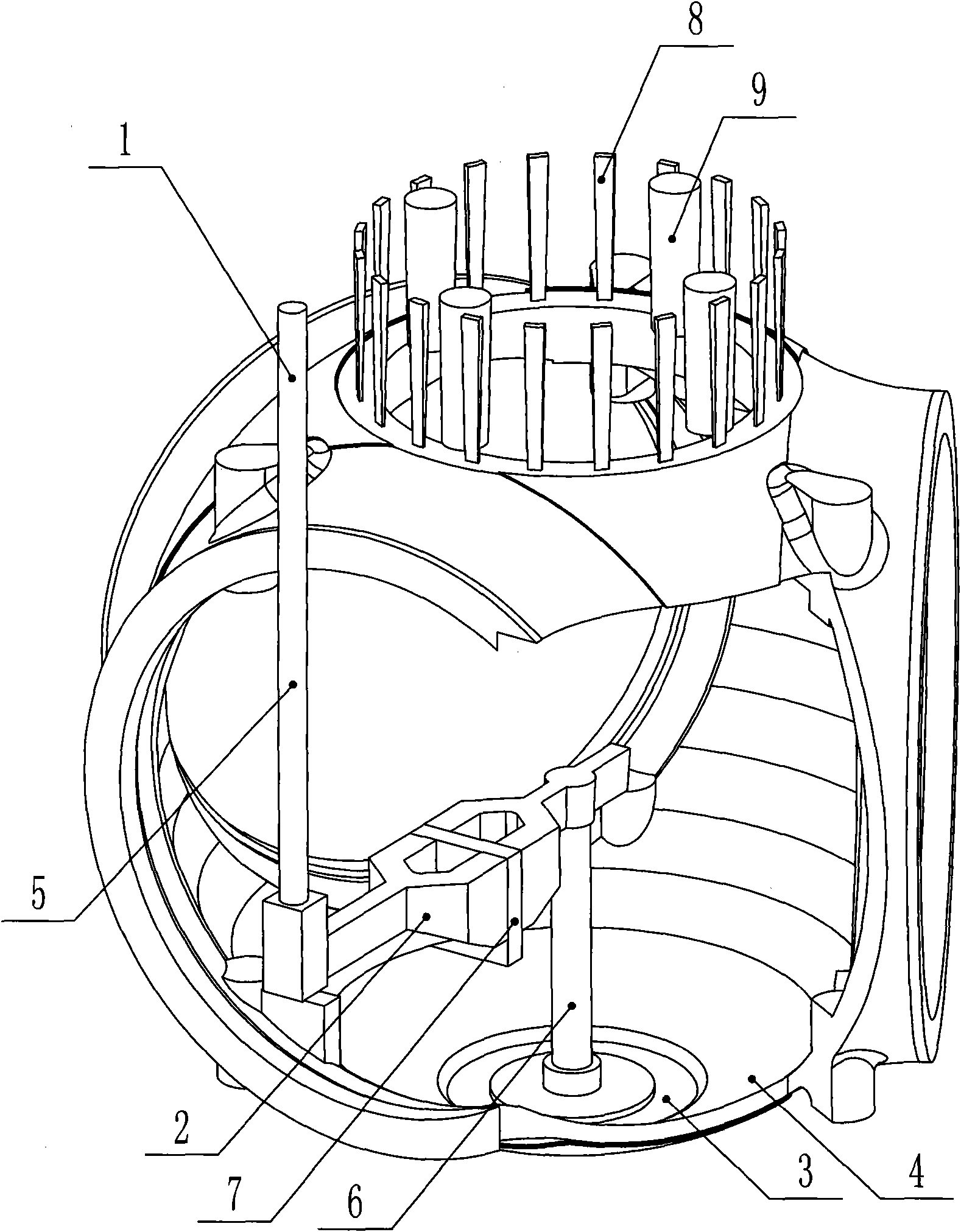

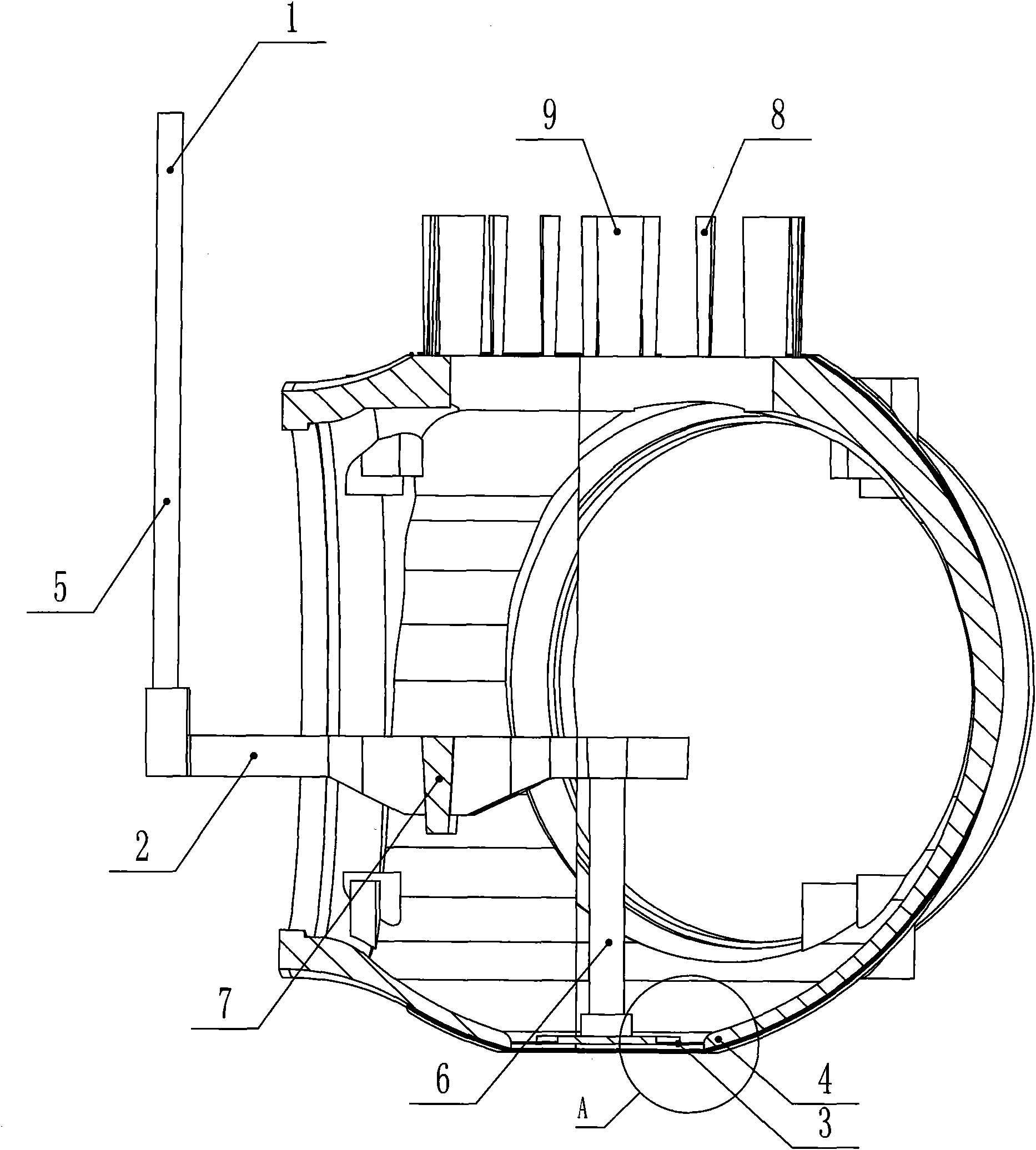

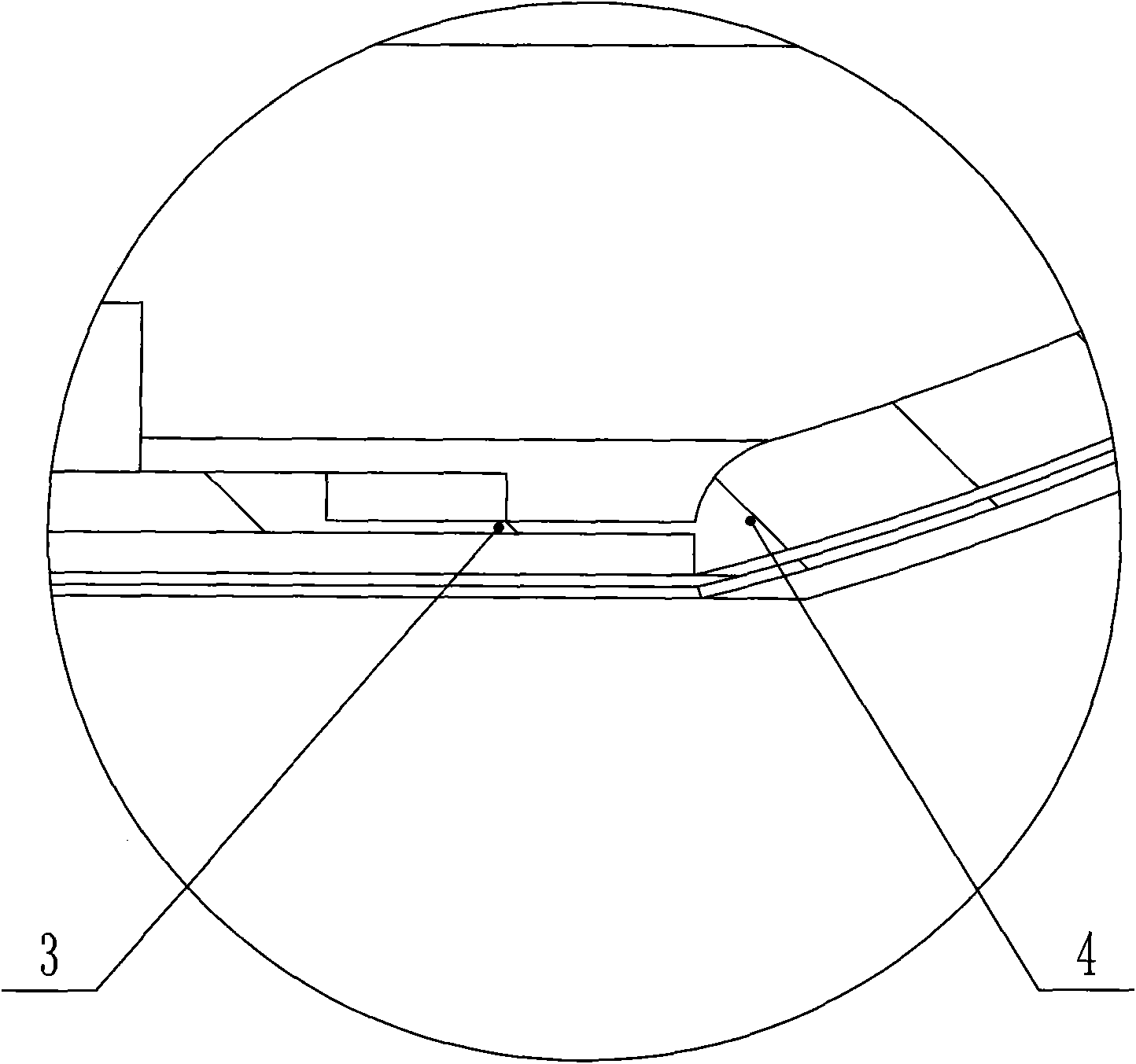

[0022] Such as Figure 1 to Figure 4 Shown, the technical scheme that the present invention adopts is:

[0023] A casting method for a wind turbine hub casting, which comprises the following steps:

[0024] 1) Mold manufacturing, carry out mold design and determination of parting surface, the mold adopts multi-box shape, the model uses Northeast Korean pine as material, the bottom frame of the model is welded by thick square pipe, and the length direction adopts the whole square tube The main purpose is to prevent the mold from deforming and improve the overall performance of the mold. Lay 2 layers of wood boards and 1 layer of plywood with a thickness of not less than 20mm on the template;

[0025] 2) For sand mold manufacturing, the ingate 3 is set in a disc shape, and the ingate 3 is set in the center of the lower end bottom sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com