High-precision full-automatic printing machine

A fully automatic, high-precision technology, used in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of difficult to achieve multi-color high-precision printing, low manual operation efficiency, easy to dry, etc., to achieve the printing environment. Stable, avoid blocking the network, avoid the effect of color channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

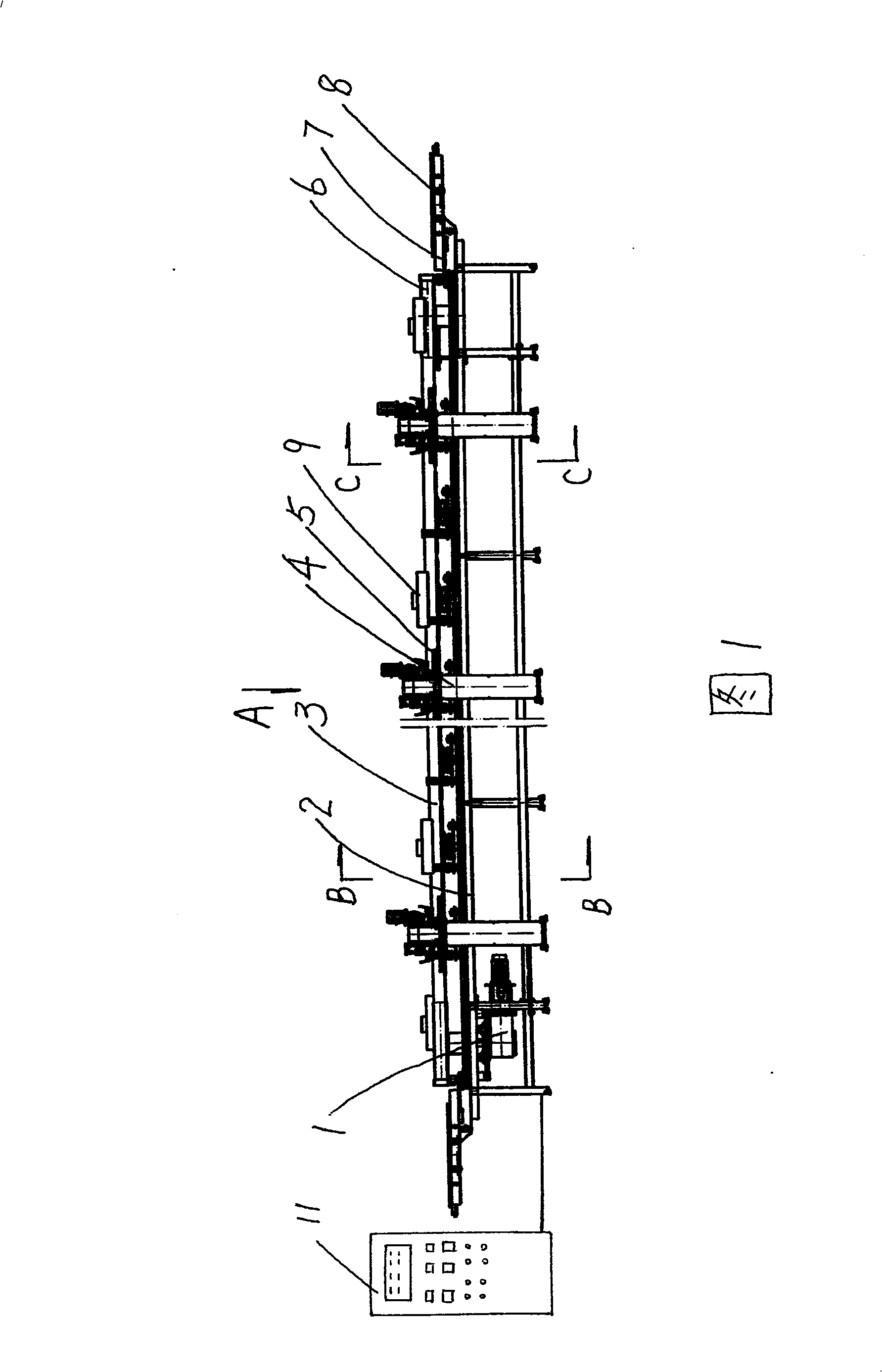

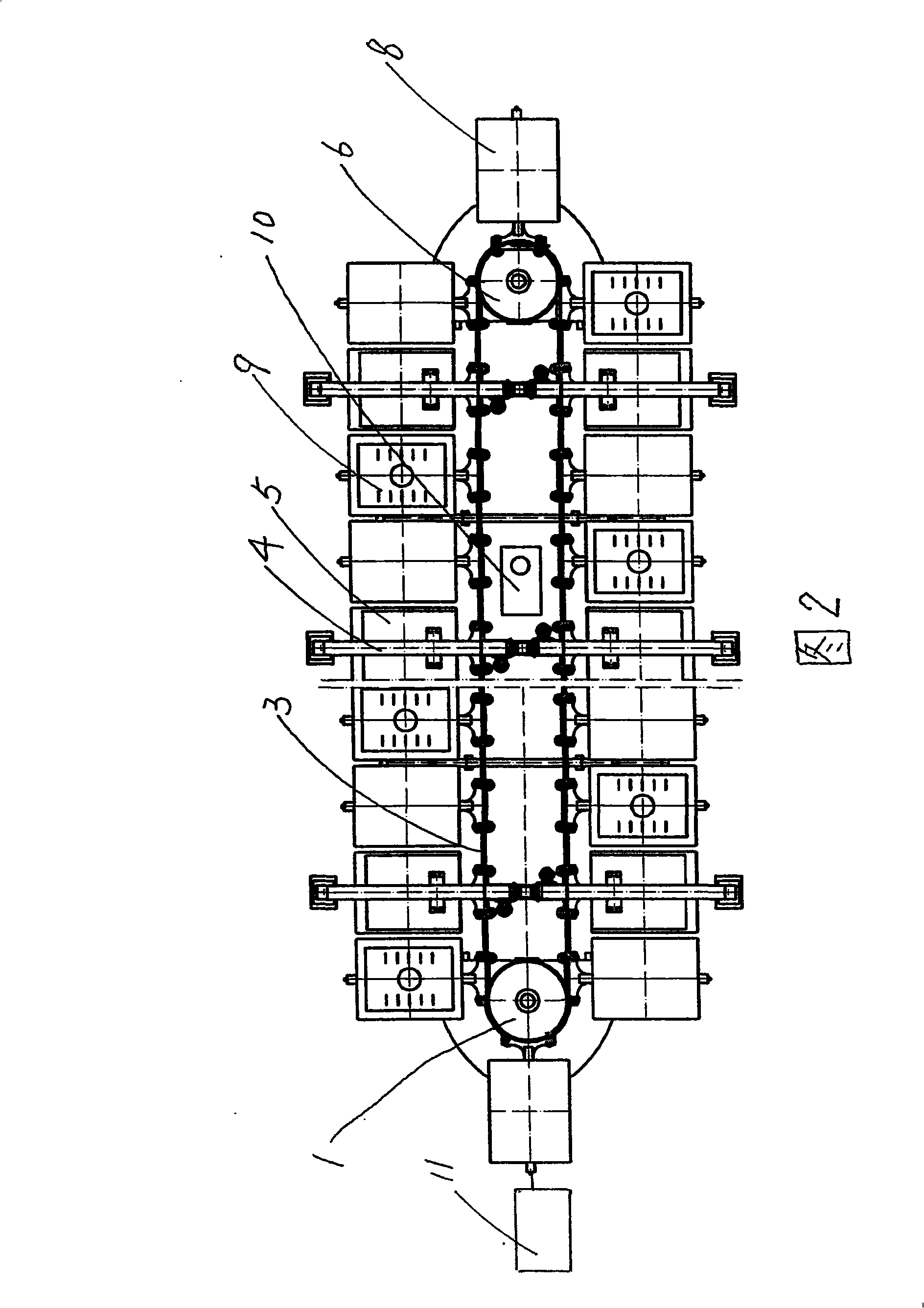

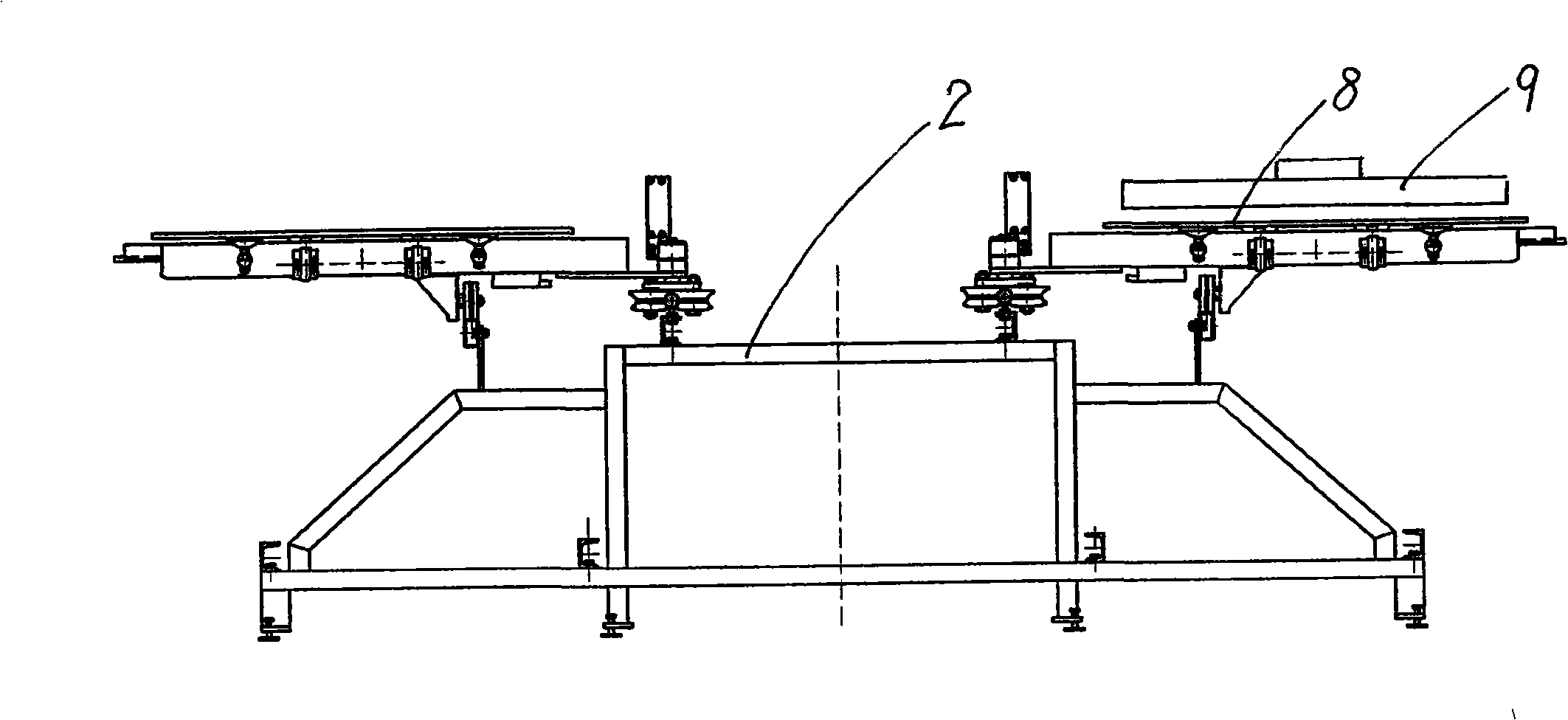

[0023] With reference to accompanying drawing 1, accompanying drawing 2, attached image 3 , the high-precision automatic printing machine of the present invention includes a main transmission part 1, a frame part 2, a transmission belt part 3, at least six sets of scraping head parts 4, a screen frame part 5, an auxiliary transmission part 6, and a platen support part 7. The platen part 8, the drying device 9, the humidifying device 10, and the control part 11. In this embodiment, the scraping head part 4 is designed into eight groups, and the main transmission part 1 is arranged on the frame part 2. The described The main transmission part 1 is a device driven by a servo motor. A transmission belt component 3 is provided on the frame component 2, and the transmission belt component 3 is a synchronous belt transmission device. The scraping head part 4 is connected with the frame part 2; the screen frame part 5 is arranged on the scraping head part 4, and the auxiliary transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com