Baking-free brick produced from residual slags generated by indirect coal liquefaction and production method thereof

A technology of liquefaction residue and production method, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effects of simple production process, short production cycle and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

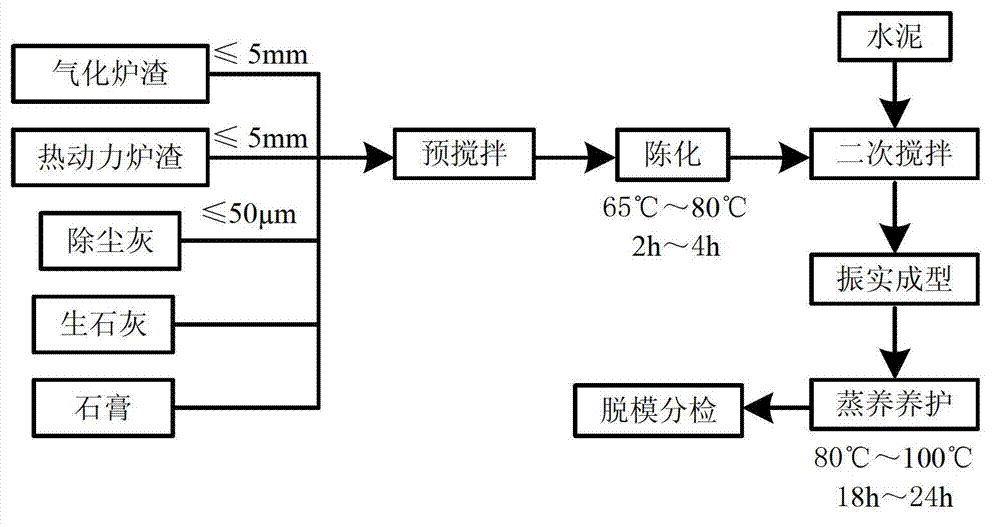

[0026] The production method of the above-mentioned coal indirect liquefaction residue unburned brick of the present invention, its preferred embodiment is:

[0027] Include the following steps:

[0028] Pre-mixing: Coal indirect liquefaction gasification slag, coal indirect liquefaction thermal power slag, coal indirect liquefaction dust, quicklime, gypsum are prepared according to the above weight ratio, add water and stir until evenly mixed;

[0029] Aging: Send the pre-mixed material into a steam curing room at 65°C to 80°C for aging for 2h to 4h;

[0030] Secondary stirring: Add the aged material to the cement with the above weight ratio, add water and stir until evenly mixed;

[0031] Molding: Send the second-mixed material to a vibrating table with a frequency of 60 times / min for 1min to 2min molding;

[0032] Steam curing: Send the formed bricks without demoulding to a steam curing room at 80°C to 100°C for 18h to 24h;

[0033] Demoulding out of the chamber for sort...

specific Embodiment

[0042] Taking coal indirect liquefaction gasification slag, coal indirect liquefaction thermal power slag, coal indirect liquefaction dust removal ash produced by an indirect coal liquefaction enterprise as research objects, gasification slag SiO 2 The content is 40.96%, Al 2 o 3 Content is 11.1%, thermodynamic slag SiO 2 The content is 62.54%, Al 2 o 3 The content is 5.54%, dust removal dust SiO 2 The content is 45.51%, Al 2 o 3 The content is 8.14%.

[0043] Such as figure 1 As shown, it includes a pre-stirring step, an aging step, a second stirring step, a molding step, a steaming step, and the like.

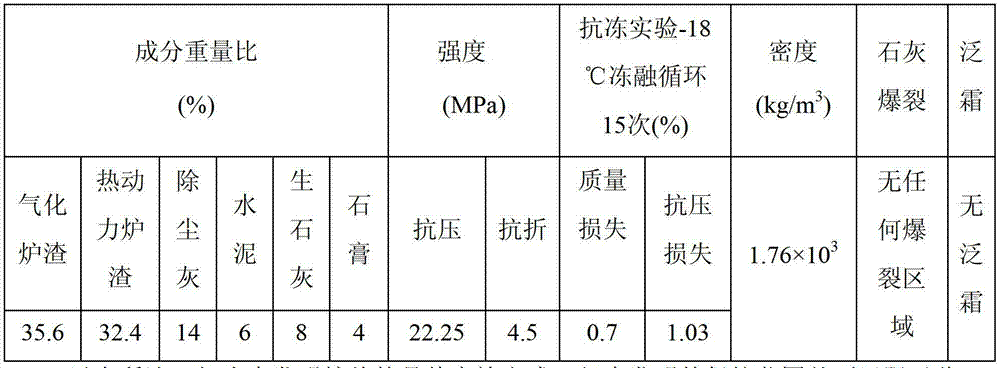

[0044] It is prepared from the following raw materials according to the following proportions: coal indirect liquefaction gasification slag 35.6%, coal indirect liquefaction thermal power slag 32.4%, coal indirect liquefaction dust removal 14%, cement 6%, quicklime 8%, gypsum 4%, The particle size of coal indirect liquefaction and gasification slag is ≤5mm, the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com