Production formula of high-temperature-resistant PVC painting film and preparation method thereof

A production formula and high temperature resistant technology, applied in the field of inkjet printing materials, can solve the problems of easy edge shrinkage, easy precipitation of plasticizers, ink absorption, defects, etc., and achieve good inkjet performance, maintain clarity, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

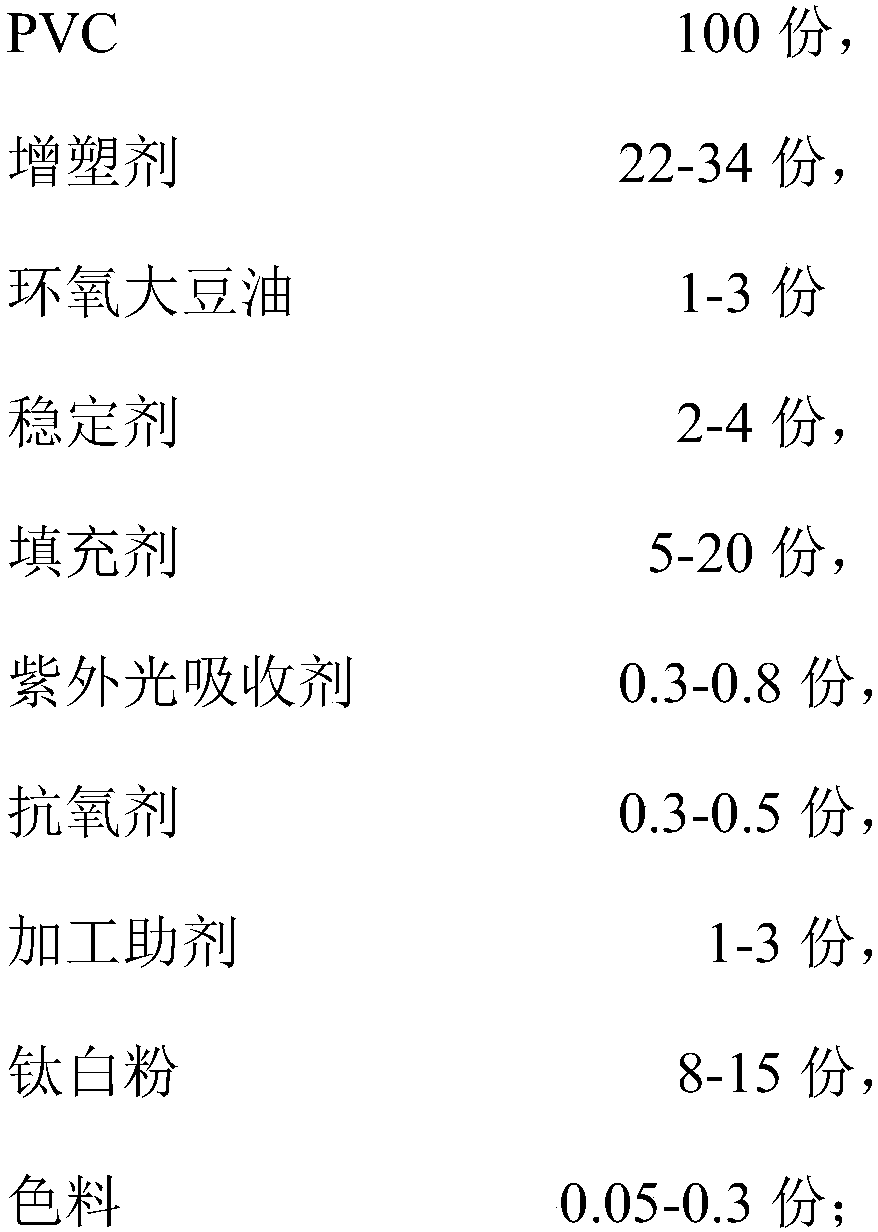

[0020] Embodiment 1: a kind of production formula of high temperature-resistant PVC spray-painted film, in parts by weight:

[0021]

[0022]

Embodiment 2

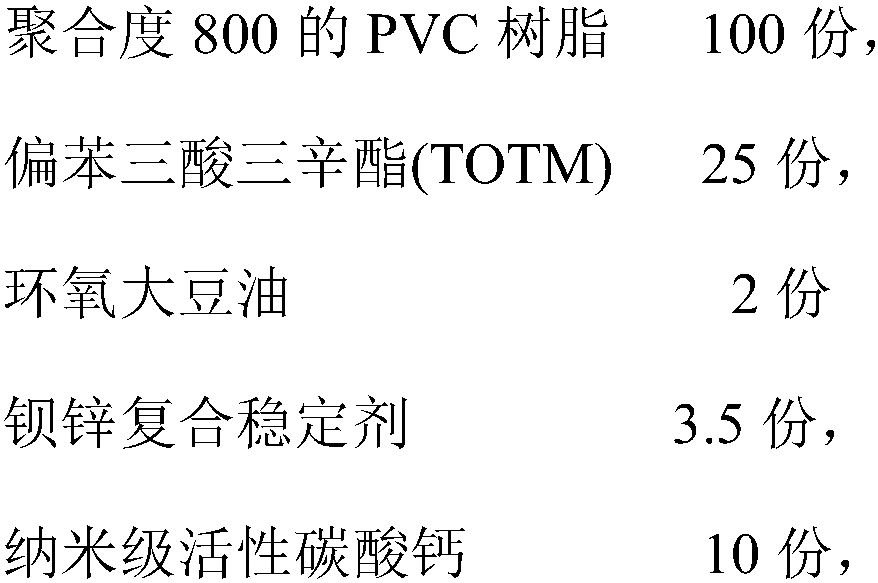

[0023] Embodiment 2: the production prescription of another kind of high-temperature-resistant PVC spray-painted film, by weight:

[0024]

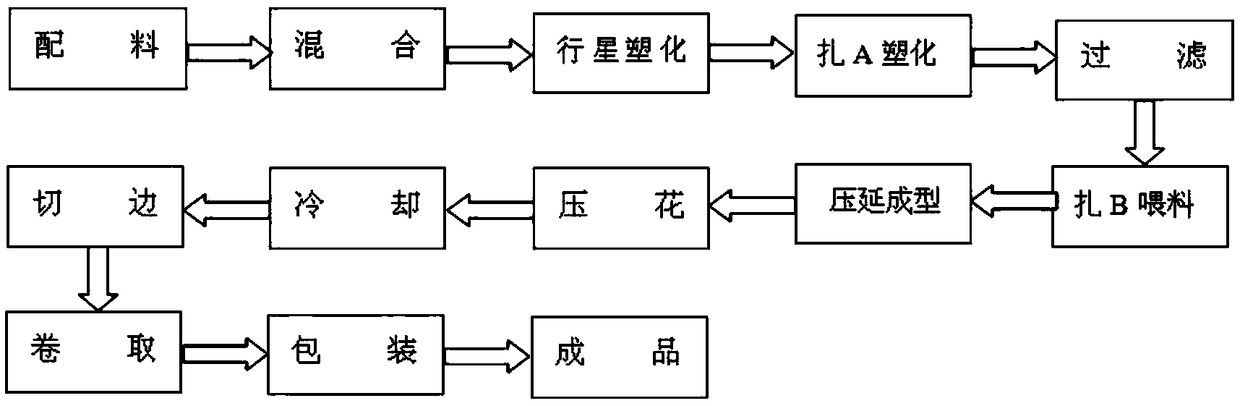

[0025] A method for making a high temperature resistant PVC spray-painted film:

[0026] Put the raw materials of the formula in Example 1 in parts by weight into a high-speed mixer and stir for 300 seconds, and control the temperature at 115°C; then put them into a low-speed cold mixer and stir until the temperature reaches 65°C, and then put them into a planetary machine for closed plasticization , the temperature of the main screw is controlled at 180°C, and the temperature of M1 is controlled at 185°C; then the material is moved to the double-roller rolling machine A for further plasticization, and the temperature is controlled at 200°C, and then the impurities are filtered through the filter, and the filter mesh is 200 mesh , The temperature of the filter is 170°C. After filtering, the material is put into the double-roller rolli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com