Silicon nitride ceramic material for backboard of mobile phone and preparation method thereof

A silicon nitride ceramic and backplane technology, which is applied in branch equipment, telephone structure, electrical components, etc., can solve problems such as affecting the operating speed and reliability of mobile phones, low thermal conductivity of zirconia, and reducing application reliability. , to avoid the card machine and performance degradation, reduce the attenuation of microwave signals, and improve the ability to receive signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

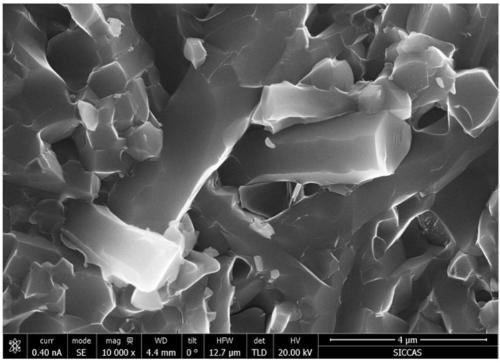

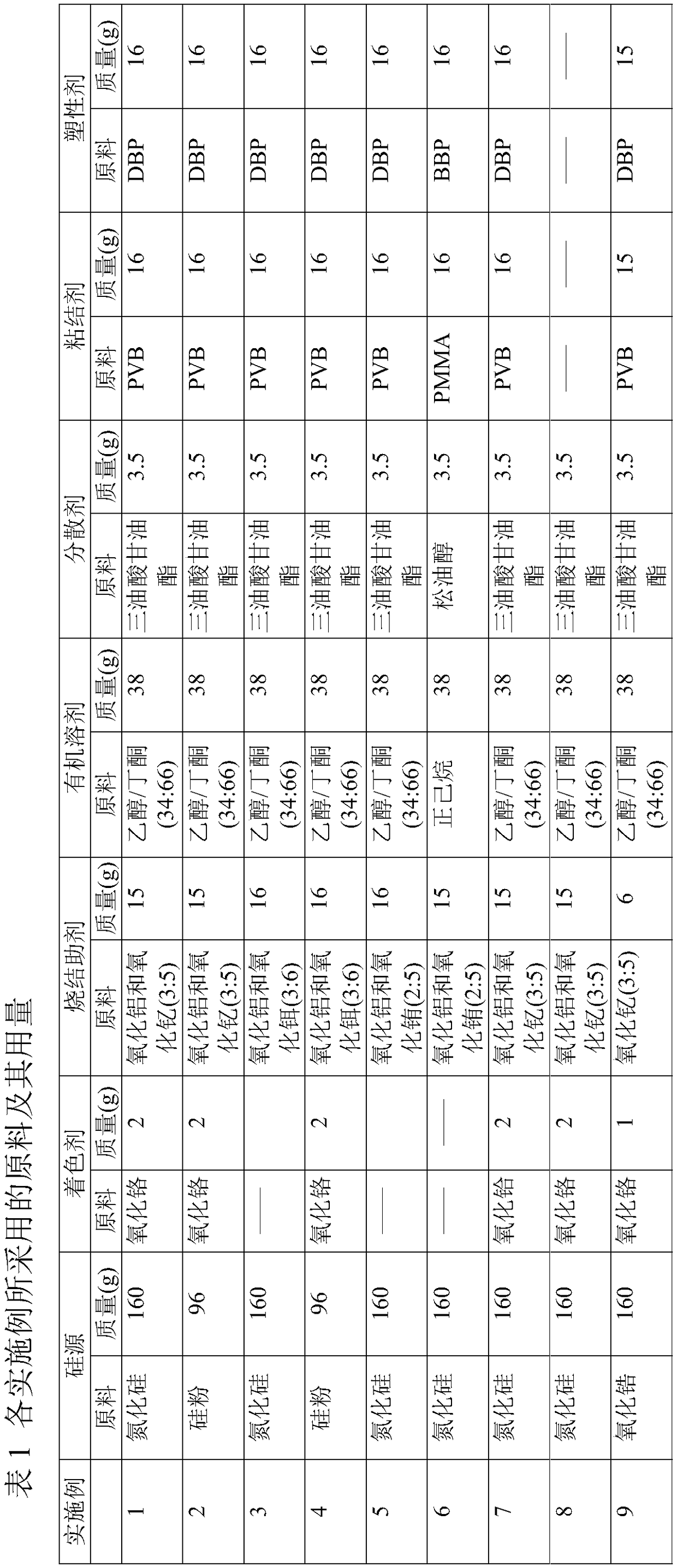

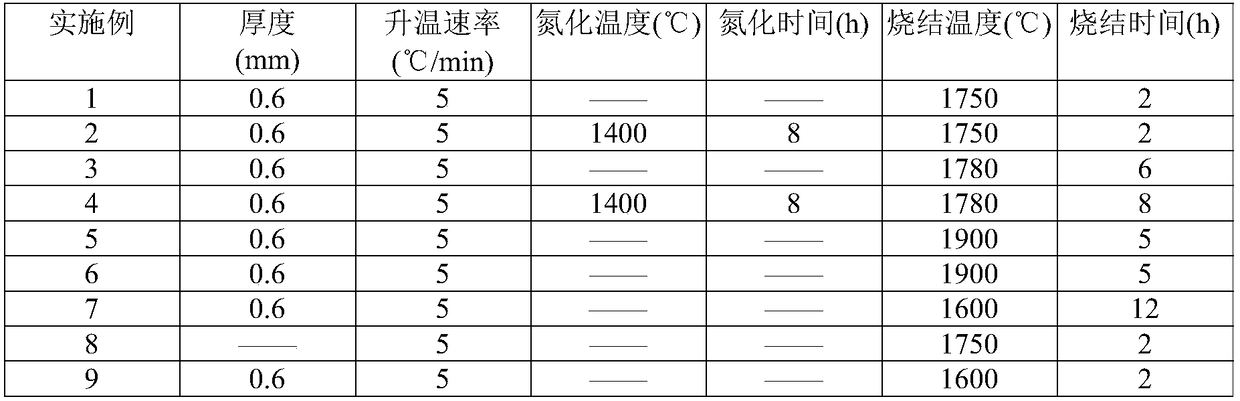

Embodiment 1

[0052] Add 160g of silicon nitride powder, 2g of chromium oxide coloring agent and 15g of sintering aid consisting of alumina and yttrium oxide (the mass ratio of alumina and yttrium oxide is 3:5) to 38g of ethanol / butanone solvent system ( The mass ratio of ethanol and butanone is 34:66). Add 3.5g glyceryl trioleate as a dispersant and carry out ball milling, the rotating speed is 380 rev / min, add 16g PVB (polyvinyl butyral) after ball milling 12h as binding agent, 16g DBP (dibutyl phthalate) ester) as a plasticizer, ball milled again for 36 hours at a speed of 200 rpm, then defoamed and cast, and a cast film with a thickness of 0.6 mm was prepared. After debonding, the cast film is sintered in a carbon tube furnace under a nitrogen atmosphere at a heating rate of 5°C / min to 1750°C and kept for 2 hours to obtain a dense and complete silicon nitride ceramic backplane. figure 1 Show the microstructure (SEM figure of section) of the silicon nitride ceramics that the present emb...

Embodiment 3

[0055] Add 160g of silicon nitride powder and 16g of sintering aid consisting of alumina and erbium oxide (the mass ratio of alumina and erbium oxide is 3:6) to 38g of ethanol / butanone solvent system (the mass ratio of ethanol and butanone The ratio is 34:66). Using 3.5g glyceryl trioleate as dispersant, the speed is 380 rpm, after ball milling for 12h, add 16g PVB as binder, 16g DBP as plasticizer, ball mill again for 24h, speed is 200 rpm, and then defoaming , cast, and prepare a cast film with a thickness of 0.6 mm. After the cast film is debonded, it is sintered in a carbon tube furnace, and the temperature is raised to 1780 °C at a rate of 5 °C / min, and the sintering is achieved by keeping the temperature for 6 hours. A dense and complete silicon nitride ceramic backplane can be obtained.

Embodiment 4

[0057] Add 96g of silicon powder and 16g of sintering aids composed of alumina and erbium oxide (the mass ratio of alumina and erbium oxide is 3:6) to 38g of ethanol / butanone solvent system (the mass ratio of ethanol and butanone is 34 : 66). Using 3.5g glyceryl trioleate as dispersant, the speed is 380 rpm, after ball milling for 12h, add 16g PVB as binder, 16g DBP as plasticizer, ball mill again for 48h, speed is 200 rpm, and then defoaming , cast, and prepare a cast film with a thickness of 0.6 mm. After debonding, the cast film was nitrided in a carbon tube furnace at 1400°C for 8 hours, and then sintered at 1780°C at a heating rate of 5°C / min for 8 hours. A dense and complete silicon nitride ceramic backplane can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com