W type connecting method of high-voltage conductive wire

A connection method and technology for high-voltage wires, applied in the direction of connection and connection by deformation and connection by permanent deformation, which can solve problems such as creep, wire falling off, and increase in contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific structure of the present invention is realized through the following embodiments and accompanying drawings.

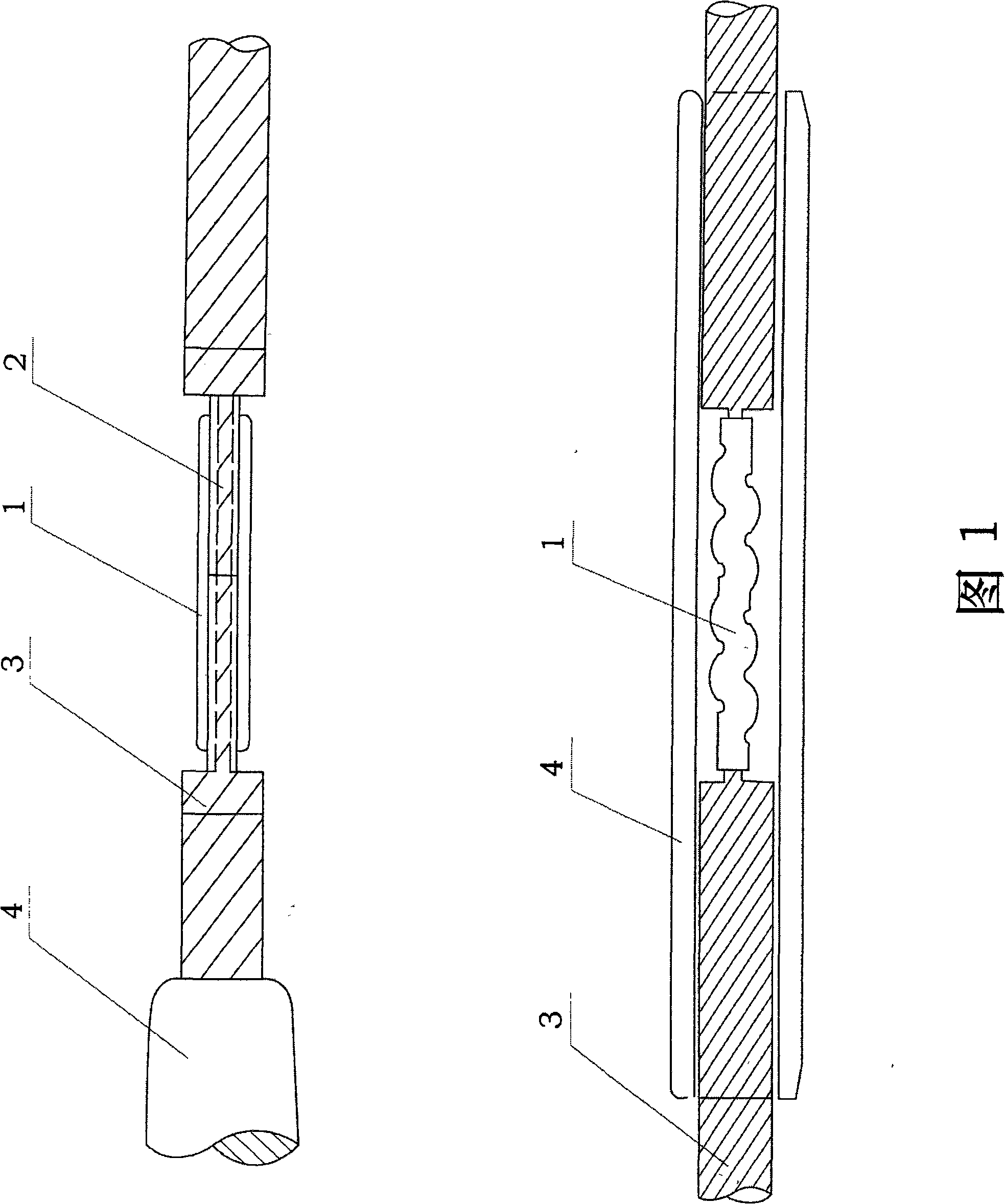

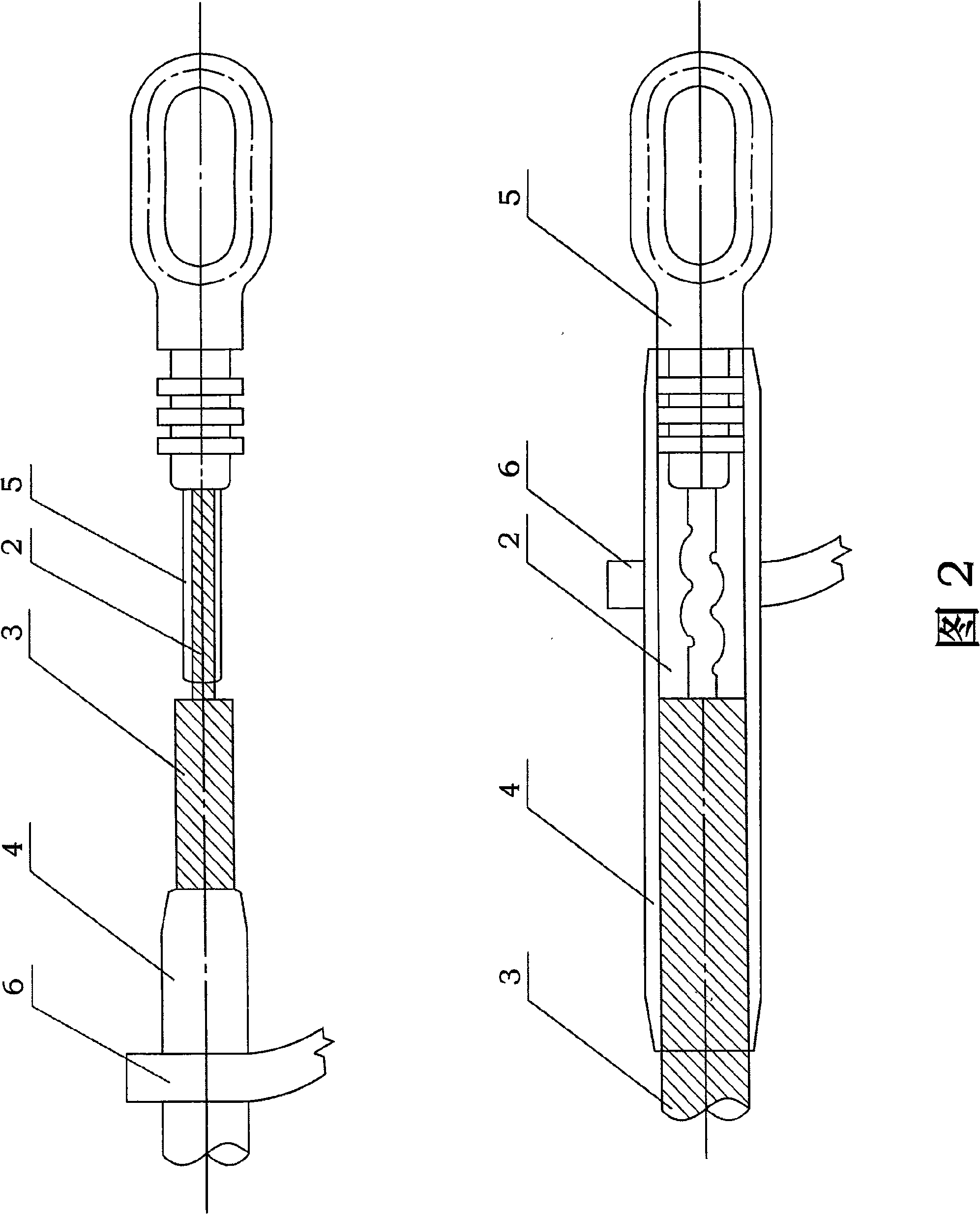

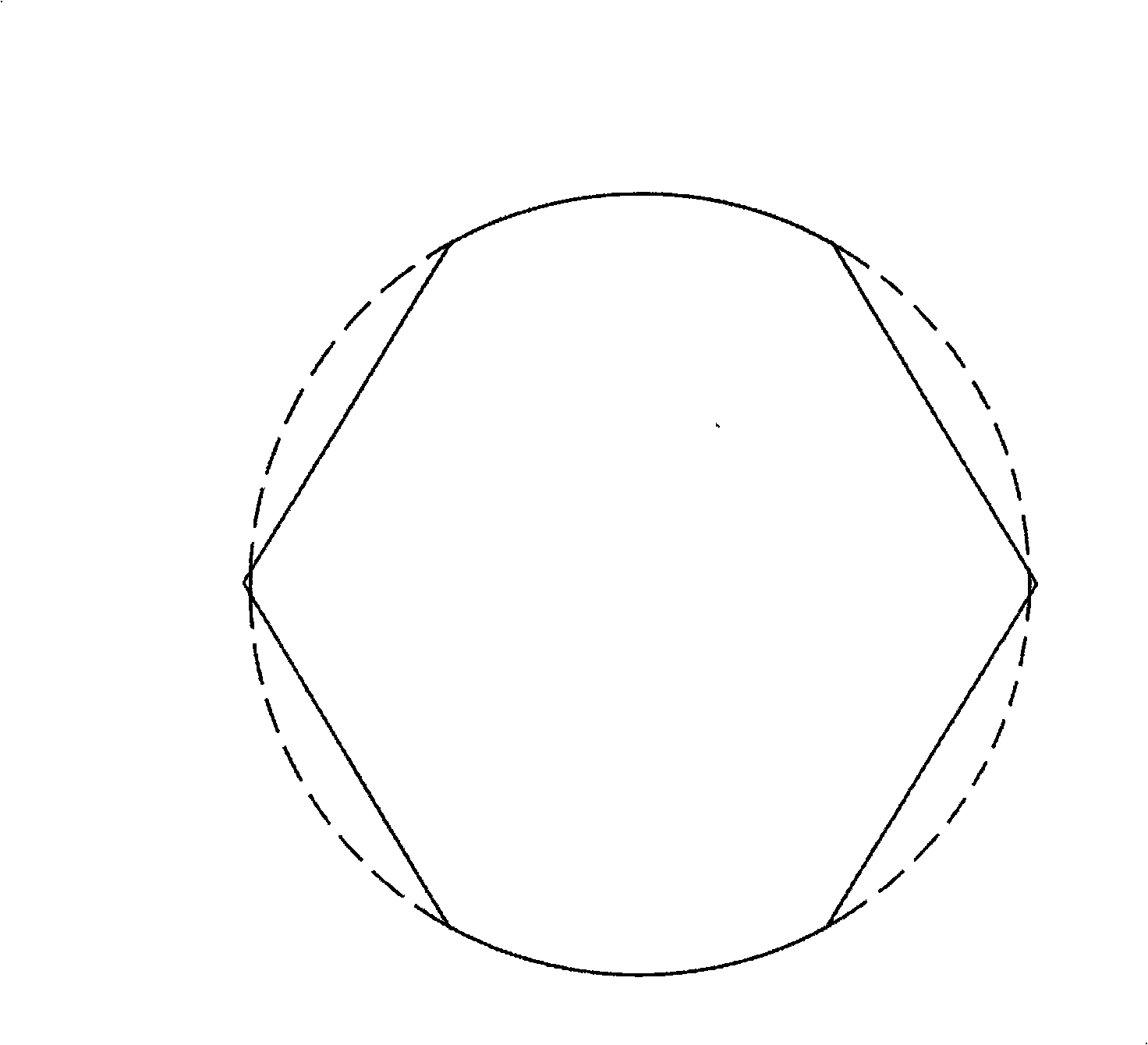

[0030] See Fig. 1, the steel core 2 aluminum strand 3 is from the unpressed steel core 2 steel pipe 1 hydraulic position and the operation sequence starts from the center, and then applies pressure to the ends of the steel pipe 1 in sequence, and finally connects the aluminum pipe 4 with the already The steel pipes 1 pressed into a W shape are overlapped and centered evenly, and then begin to exert hexagonal confining pressure on the aluminum pipe 4. The operating points of the confining pressure on the aluminum pipe 4 are all the same as those of the connecting pipe in the prior art, forming a connecting pipe A new type of crimping that learns from each other and complements each other. Due to the special shape of the two-in-one technology of 1W type crimping of steel pipe and 4-in-one crimping of aluminum tube, the splicing pipe of the new two-in-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com