Silicon-carbon composite material, preparation method thereof, negative electrode, power battery and electric automobile

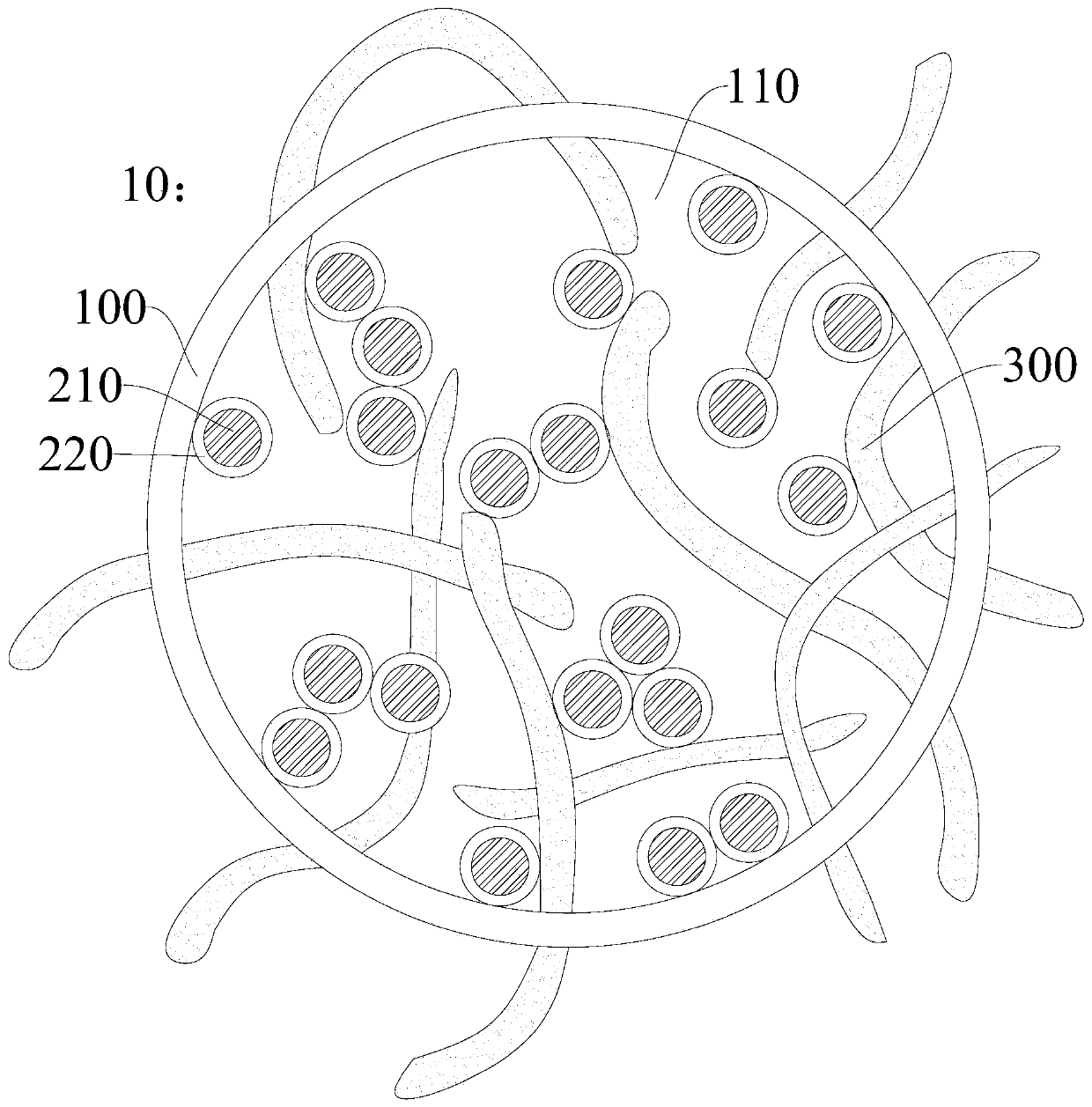

A silicon-carbon composite material and nano-carbon material technology, applied in the field of materials, can solve the problems of excessive capacity decay, high volume expansion rate, poor electrical conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

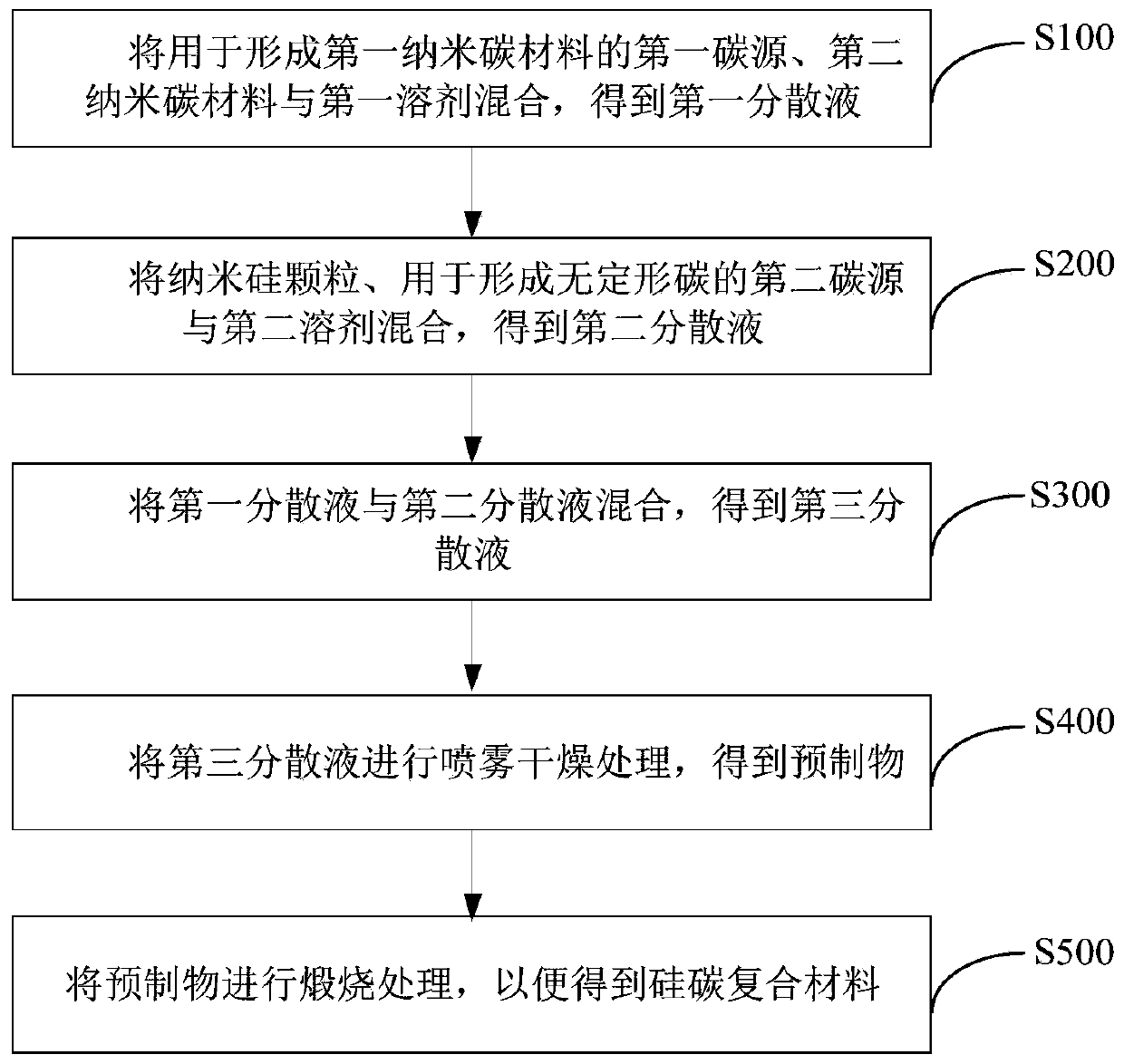

Method used

Image

Examples

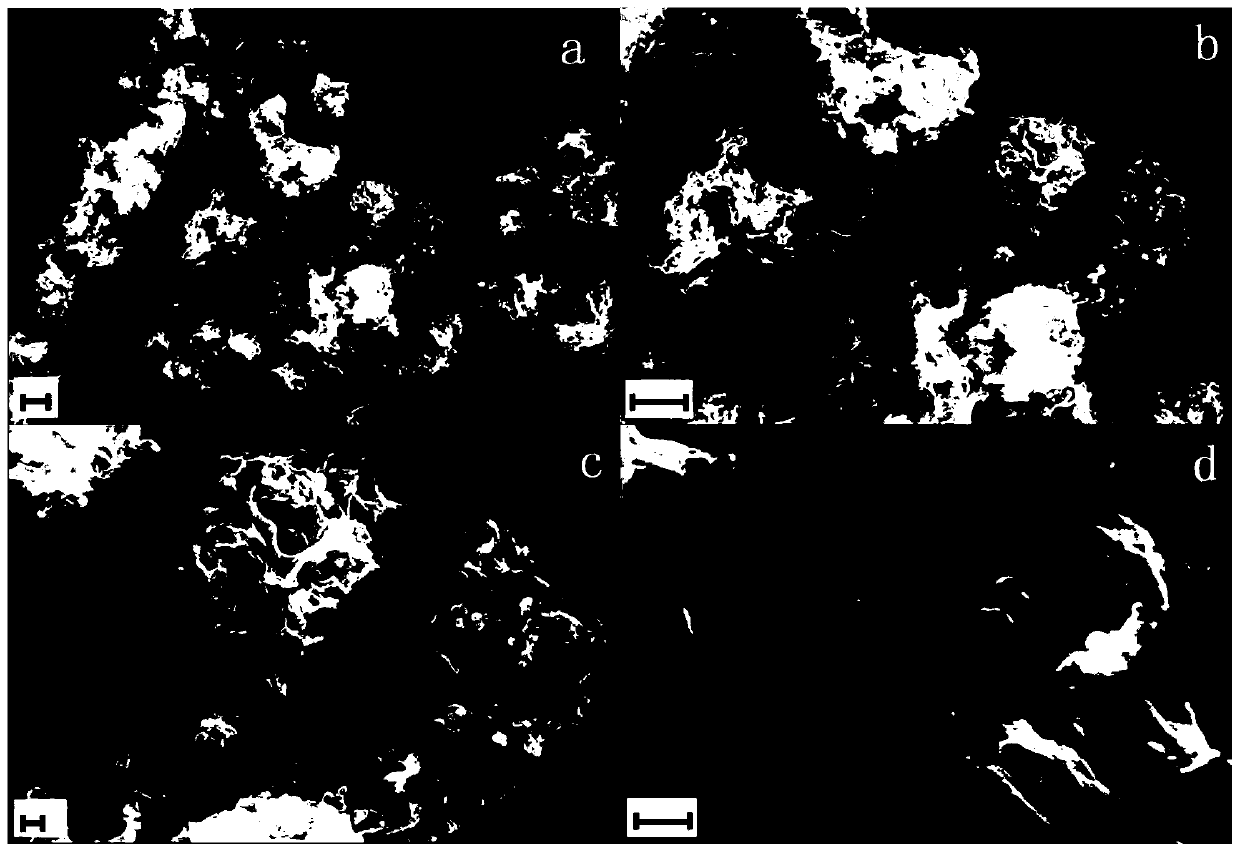

Embodiment 1

[0074] The graphene oxide aqueous solution with a mass percentage content of 1.34% was prepared into 1L of graphene oxide aqueous solution with a mass concentration of 1mg / mL, and the obtained mixture was stirred and dispersed for 1h at a stirring rate of 300rpm / min, and then added to the obtained mixture 83.34 g of a dispersion of carbon nanotubes with a mass percentage of 0.2% was added to the mixture, stirred and dispersed for 1 hour at a stirring rate of 400 rpm / min, and the first dispersion was obtained. Weigh 7g of polyvinylpyrrolidone and dissolve it in 500mL of deionized water, then weigh 1g of silicon nanoparticles (30nm in particle size) and add it to the solution formed by polyvinylpyrrolidone, ultrasonically stir for 1h, and the stirring rate is 220rpm / min , to obtain the second dispersion. The aforementioned first dispersion liquid was stirred at a rotational speed of 330 rpm / min, and the second dispersion liquid was added dropwise into the first dispersion liquid...

Embodiment 2

[0082]The graphene oxide aqueous solution with a mass percentage content of 1.34% was prepared into 1L of graphene oxide aqueous solution with a mass concentration of 1mg / mL, and the obtained mixture was stirred and dispersed for 1h at a stirring rate of 300rpm / min, and then added to the obtained mixture 41.67 g of a dispersion of carbon nanotubes with a mass percentage of 0.2% was added to the mixture, stirred and dispersed for 1 hour at a stirring rate of 400 rpm / min, and the first dispersion was obtained. Weigh 7g of polyvinylpyrrolidone and dissolve it in 500mL of deionized water, then weigh 1g of silicon nanoparticles (30nm in particle size) and add it to the solution formed by polyvinylpyrrolidone, ultrasonically stir for 1h, and the stirring rate is 220rpm / min , to obtain the second dispersion. The aforementioned first dispersion liquid was stirred at a rotational speed of 330 rpm / min, and the second dispersion liquid was added dropwise into the first dispersion liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com