Stable combustion anti-slag gap type W-shaped flame boiler apparatus

An anti-slagging and gap-type technology, applied in combustion equipment, lighting and heating equipment, etc., can solve the problems of unreasonable combustion structure, easy slagging in the lower furnace, poor flame stability of pulverized coal gas flow, etc. performance, improve flame stability, and organize reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

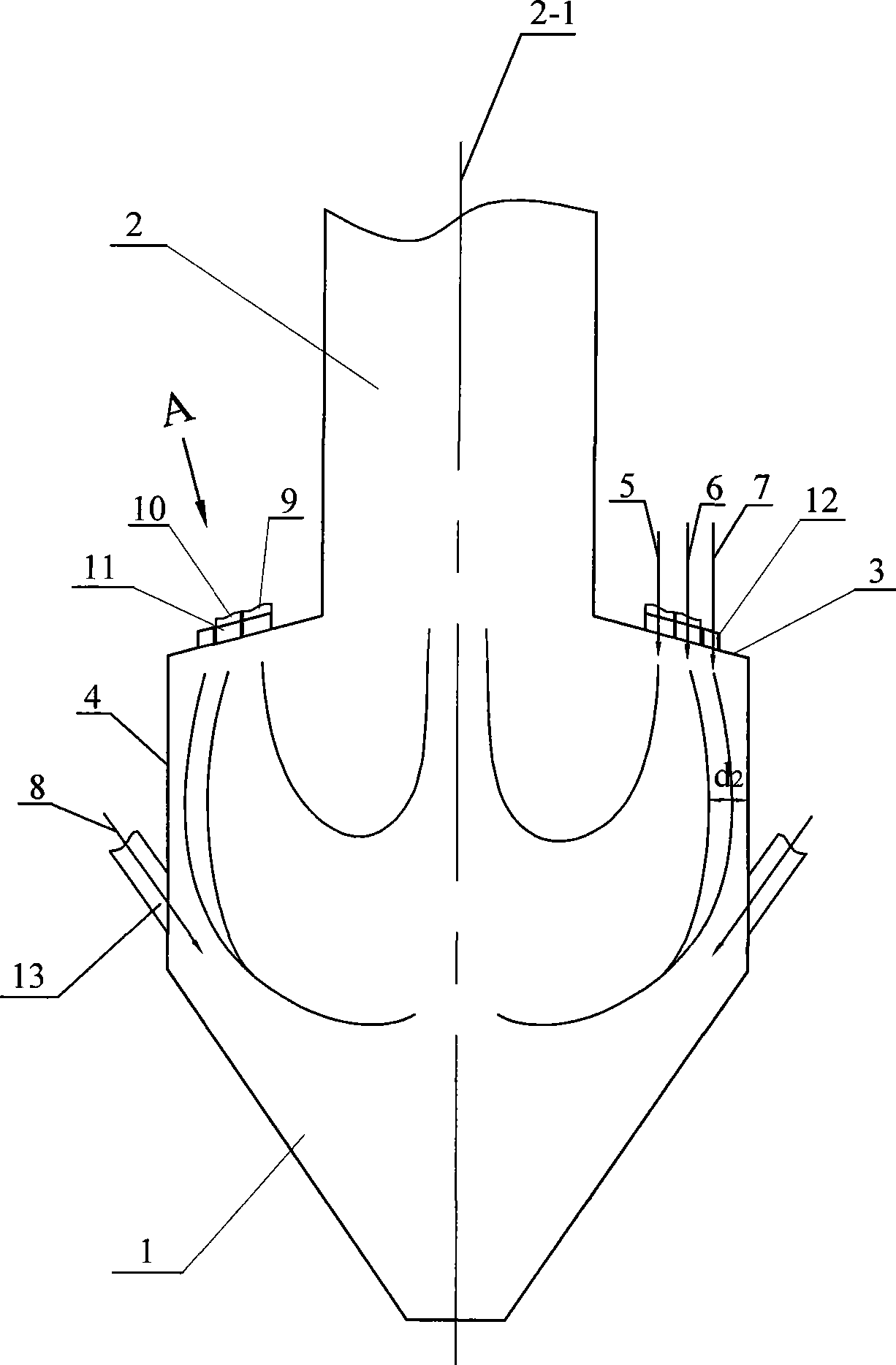

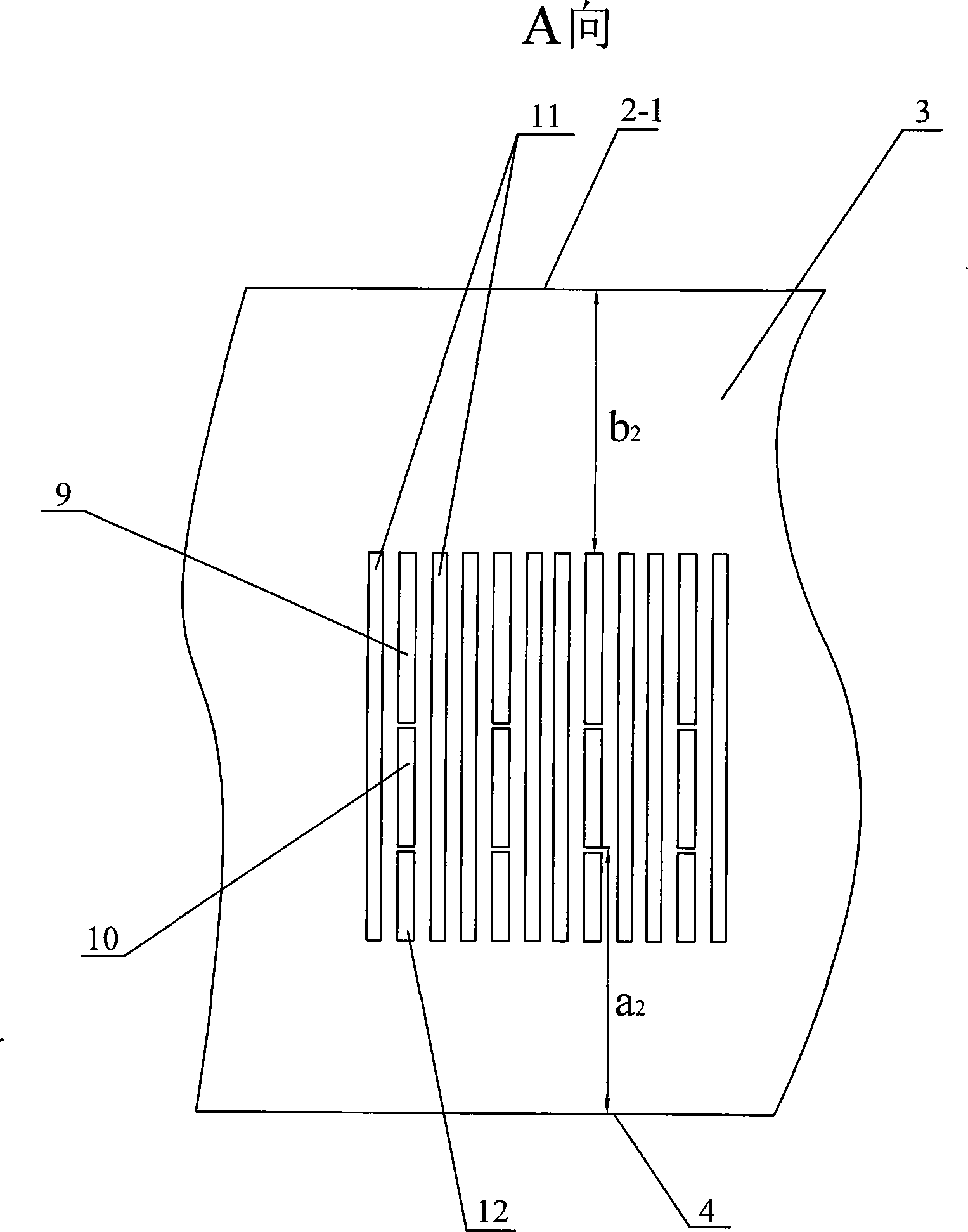

[0007] Specific implementation mode one: combine figure 1 and figure 2 This embodiment is described. This embodiment is composed of the lower furnace 1, the upper furnace 2, the front and rear arches 3 and the front and rear water walls 4. The upper furnace 2, the front and rear arches 3, the front and rear water walls 4 and the lower furnace 1 are from top to bottom. The bottom is connected into one body, the lower part of the front and rear walls 4 is provided with two symmetrical rows of tertiary air nozzles 13, and the front and rear arches 3 are provided with primary air nozzles 9, exhaust air nozzles 10 and secondary air nozzles 11. The anti-slagging secondary air spout 12 is also provided on the front and rear arches 3; the primary air spout 9 is opened on the front and rear arches 3 near the furnace center 2-1 side, and the secondary air spout 11 and the primary air spout 9 are arranged at intervals, the anti-slagging secondary air nozzles 12 are opened on the front...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 2 Describe this embodiment, the upper edge of the secondary air nozzle 11 of this embodiment is flush with the upper edge of the primary air nozzle 9, and the lower edge of the secondary air nozzle 11 is flush with the lower edge of the anti-slagging secondary air nozzle 12 , the distance from the upper edge of the primary air nozzle 9 to the hearth center 2-1 is b 2 . In this way, the primary air jet is closer to the center of the high-temperature furnace (b 2 1 ), the flame stability of pulverized coal flow is better. Other components and connections are the same as those in the first embodiment.

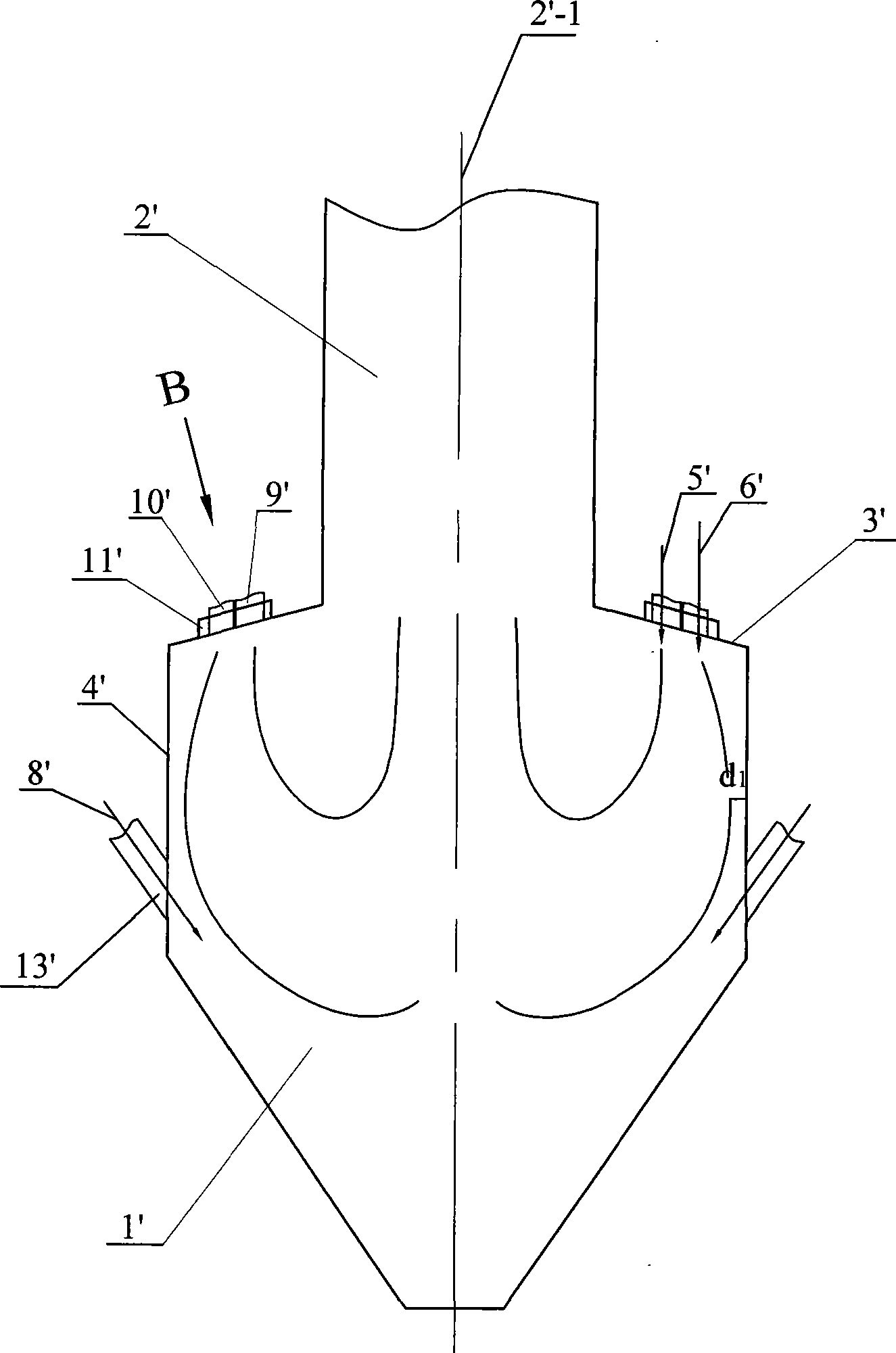

[0009] Depend on figure 1 and figure 2 Compared, image 3 and Figure 4 It can be seen from the comparison that the exhaust gas is farther away from the water-cooled walls of the front and rear walls of the lower furnace after the arrangement structure of the present invention is adopted in the slot type W-type f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com