High-elasticity heat-resistant chinlon 6 and preparation method

A high-elasticity and heat-resistant technology, which is applied in the preparation of nylon and textile fields, can solve the problems of reduced spinnability of chips, increase of waste yarn rate, spinning end breakage, etc., and achieve good resilience, not easy to damage, and improve toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

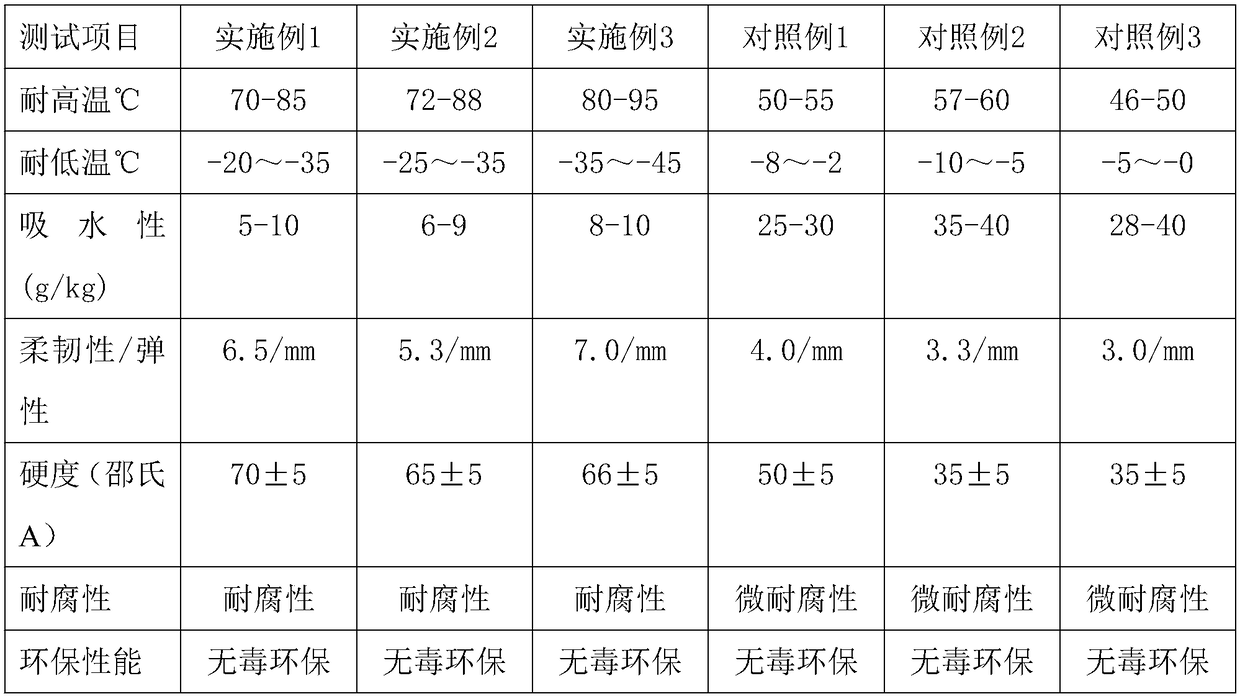

Examples

Embodiment 1

[0047] A high-elasticity and heat-resistant nylon 6 and its preparation method.

[0048] In order to achieve the above objective, the present invention provides the following technical solutions:

[0049] The high elastic heat-resistant nylon 6 is composed of the following raw materials in parts by weight: 0.6 parts of precipitated barium sulfate, 1.5 parts of diethyl phthalate, 130 parts of caprolactam, 4 parts of expanded polytetrafluoroethylene, and hypophosphorous acid monohydrate 3 parts of sodium, 2 parts of paraformaldehyde, 0.2 parts of 35-37% hydrochloric acid, 4 parts of bisphenol A polycarbonate, 5 parts of aluminum chloride hexahydrate, 0.15 parts of triethylamine, 0.6 parts of ammonium oxalate, 2- 0.8 parts of mercaptan benzimidazole, 2.5 parts of dodecyl mercaptan, 1.5 parts of dodecyl trimethyl ammonium chloride, 26 parts of plant fiber lignin, 2 parts of calcium petroleum sulfonate, 800.2 parts of polysorbate , 1.4 parts of potassium dihydrogen phosphate.

[0050] T...

Embodiment 2

[0067] The high-elasticity and heat-resistant nylon 6 is composed of the following raw materials in parts by weight: 1.2 parts of microcrystalline cellulose, 0.5 parts of diethyl phthalate, 120 parts of caprolactam, 2.5 parts of expanded polytetrafluoroethylene, monohydrate 3 parts of sodium phosphate, 2 parts of paraformaldehyde, 0.2 parts of 30-40% hydrochloric acid, 4 parts of bisphenol A polycarbonate, 5 parts of aluminum chloride hexahydrate, 0.1 part of triethylamine, 0.6 part of ammonium oxalate, 2 -0.7 parts of mercaptan benzimidazole, 2.5 parts of dodecyl mercaptan, 2 parts of dodecyl trimethyl ammonium chloride, 16 parts of plant fiber lignin, 1 part of calcium petroleum sulfonate, polysorbate 800.2 Parts, 1.4 parts of potassium dihydrogen phosphate.

[0068] In the preparation method of the high-elasticity and heat-resistant nylon 6, the steps of the cold treatment are as follows: the further cold treatment in the preparation process is divided into the first freezing ...

Embodiment 3

[0072] The high-elasticity and heat-resistant nylon 6 is composed of the following raw materials in parts by weight: 1.0 part of microcrystalline cellulose, 1.2 parts of diethyl phthalate, 130 parts of caprolactam, 2 parts of expanded polytetrafluoroethylene, monohydrate 3 parts of sodium phosphate, 2 parts of paraformaldehyde, 0.2 parts of 30-40% hydrochloric acid, 4 parts of bisphenol A polycarbonate, 5 parts of aluminum chloride hexahydrate, 0.1 part of triethylamine, 0.6 part of ammonium oxalate, 2 -0.7 parts of mercaptan benzimidazole, 2 parts of dodecyl mercaptan, 1 part of dodecyl trimethyl ammonium chloride, 16 parts of plant fiber lignin, 1.5 parts of calcium petroleum sulfonate, and 800.1 of polysorbate Parts, 1.4 parts of potassium dihydrogen phosphate.

[0073] In the preparation method of the high-elasticity and heat-resistant nylon 6, the step granulation conditions are as follows: further, the melt extrusion granulation conditions in step 10 are: divided into three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com