Rapid cross section manufacture and sub-surface micro-crack detection method of single crystal semiconductor substrate

A single crystal semiconductor and detection method technology, which is applied in the preparation of test samples, optical test flaws/defects, etc., can solve problems such as low efficiency and complex production methods, and can ensure accuracy, intuitive detection results, and position accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the detection of subsurface microcracks is carried out on the single crystal SiC substrate obtained under the grinding conditions of 325# diamond grinding wheel, the workpiece rotation speed is 151rpm, the grinding wheel rotation speed is 3000rpm, and the grinding wheel feed speed is 5 μm / s. include:

[0029] Step 1: Put the ground single-crystal SiC substrate into acetone for ultrasonic cleaning for 5 minutes, then put it into deionized water for 2 minutes, and finally put it into a dryer for drying.

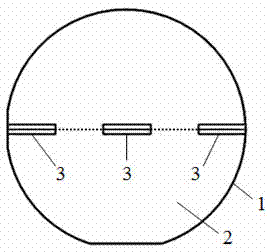

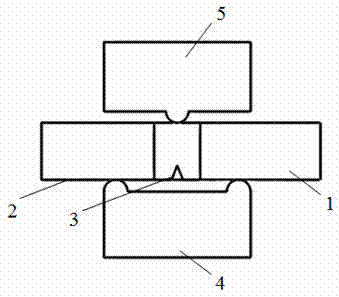

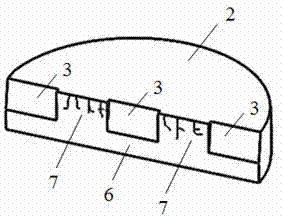

[0030] Step 2: If figure 1 As shown, the single crystal SiC substrate is placed on the center of the workbench of the UVCAS-5W-B semi-automatic wafer cutting machine with the grinding surface facing up, and three micro-grooves 3 are processed along the same straight line direction of the surface to be tested 2, The actual output current value of the power supply of the wafer laser cutting machine is 40A, the cutting speed is 1mm / s, and the micro groo...

Embodiment 2

[0034] In this embodiment, the detection of subsurface microcracks is carried out on the single crystal SiC substrate obtained under the grinding conditions of 8000# diamond grinding wheel, the workpiece rotation speed is 151rpm, the grinding wheel rotation speed is 3000rpm, and the grinding wheel feed speed is 0.1 μm / s. Steps include:

[0035] Step 1: put the ground single crystal SiC substrate into alcohol for ultrasonic cleaning for 5 minutes, then put it into deionized water for 2 minutes, and finally put it into a dryer for drying.

[0036] Step 2: If figure 1 As shown, the single crystal SiC substrate is placed on the center of the workbench of the UVCAS-5W-B semi-automatic wafer cutting machine with the grinding surface facing up, and two micro-grooves 3 are processed along the same straight line direction of the surface to be tested 2, and the The actual output current value of the power supply of the wafer laser cutting machine is 35A, the cutting speed is 0.5mm / s, a...

Embodiment 3

[0040] In this embodiment, subsurface microcrack detection is carried out on a single crystal SiC substrate obtained by grinding under the process conditions of a loading weight of 3080g, a grinding disc rotation speed of 80rpm, and a processing time of 30min with W14 diamond abrasive, and the steps include:

[0041] Step 1: Put the ground single-crystal SiC substrate into electronic cleaner DZ-1 for ultrasonic cleaning for 5 minutes, then put it in deionized water for 2 minutes, and finally put it in a dryer for drying.

[0042] Step 2: If figure 1 As shown, the single crystal SiC substrate is placed on the center of the workbench of the UVCAS-5W-B semi-automatic wafer cutting machine with the grinding surface facing up, and two micro-grooves 3 are processed along the same straight line direction of the surface to be tested 2, and the wafer The actual output current value of the power supply of the circular laser cutting machine is 30A, the cutting speed is 0.1mm / s, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com