Cathode active material and preparation method and lithium ion battery thereof

A negative electrode active material, water-soluble technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor battery charge and discharge efficiency and cycle performance, uneven tin dispersion, etc., to reduce decomposition and ensure cycle performance , Improve the effect of charging and discharging efficiency and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

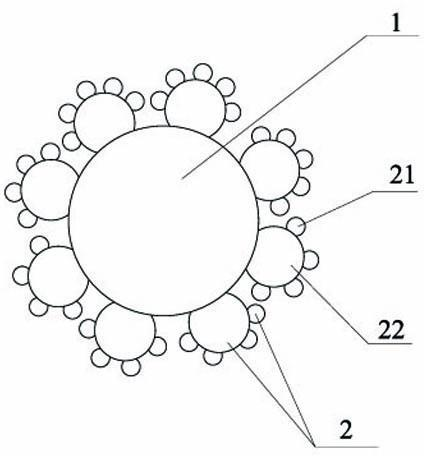

[0028] The present invention also provides a preparation method of the negative electrode active material, comprising the following steps:

[0029] 1) Surface treatment of graphite;

[0030] 2) Mix the surface-treated graphite with a water-soluble aluminum compound, and then add a metal salt solution to obtain a mixed system; the metal salt solution contains a water-soluble tin salt, and selectively contains a water-soluble M salt; Chemically active metal elements;

[0031] 3) Add water-soluble alkaline substances to the mixed system in step 2), until the precipitation is complete, and dry to obtain the precursor;

[0032] 4) Sintering the precursor to obtain the negative electrode active material.

[0033] According to the method of the present invention, the surface treatment of graphite is known to those skilled in the art, that is, immersing graphite in acid or alkali to acidify or alkalinize. Acidification or alkalization treatment, on the one hand, removes incompatibl...

Embodiment 1

[0052] (1) Blend 200g of sodium hydroxide with a concentration of 50wt% and 50g of graphite, heat to 60°C, stir for 3h, wash and filter with deionized water, and dry at 60°C for 12h to obtain alkalized graphite;

[0053] (2) Weigh 0.04mol SnSO 4 Dissolve in water to make 400mL metal salt solution; Add the alkalized graphite to the solution containing 0.01mol / L citric acid and 0.005mol / L AlCl 3 1L of mixed solution, then add metal salt solution, blend and stir to obtain a mixed system;

[0054] (3) Heat the mixed system in a water bath to 80°C, add 0.1mol / LNH dropwise to the mixed system 4 HCO 3 The solution was stirred at a constant temperature of 80°C for 2 hours until the precipitation was complete. After filtration, the precipitate was vacuum-baked at 80°C for 12 hours to obtain a precursor sample, which was designated as A1;

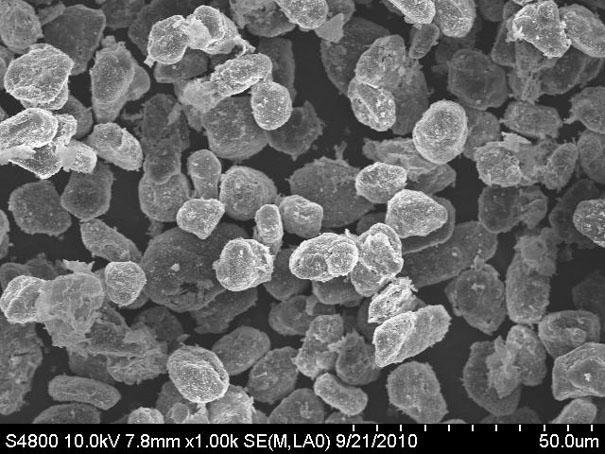

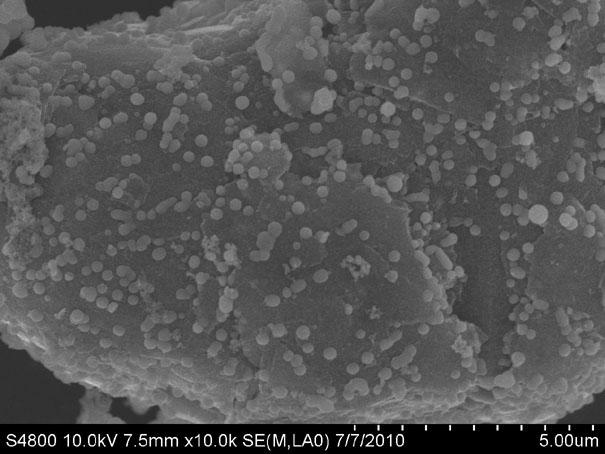

[0055] (4) Vacuum sintering the precursor sample A1 at 800° C. for 10 h to obtain the negative electrode active material sample of this embodimen...

Embodiment 2

[0064] (1) Blend 200g of nitric acid with a concentration of 34wt% and 50g of graphite, heat to 60°C, stir for 3h, wash and filter with deionized water, and dry at 60°C for 12h to obtain acidified graphite;

[0065] (2) Weigh 0.04mol SnSO 4 and 0.06mol CoCl 3 Dissolve in water to make 400mL metal salt solution; add the acidified graphite to the solution containing 0.01mol / L glucose and 0.005mol / L 31L of mixed solution, then add metal salt solution, blend and stir to obtain a mixed system;

[0066] (3) Heat the mixed system in a water bath to 80°C, and add 0.1mol / LNH dropwise to the mixed system 4 HCO 3 The solution was stirred at a constant temperature of 80°C for 2 hours until the precipitation was complete. After filtration, the precipitate was vacuum-baked at 80°C for 12 hours to obtain a precursor sample, which was designated as A2;

[0067] (4) The precursor sample A2 was sintered at 800° C. for 10 h under the protection of nitrogen atmosphere to obtain the negative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com