Flower-shaped mesoporous titanium dioxide material and preparation method and application thereof

A mesoporous titanium dioxide, flower-like technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of no visible light response, limited application, low photocatalytic efficiency, etc., to improve electrochemical performance. , The process conditions are not harsh, and the preparation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

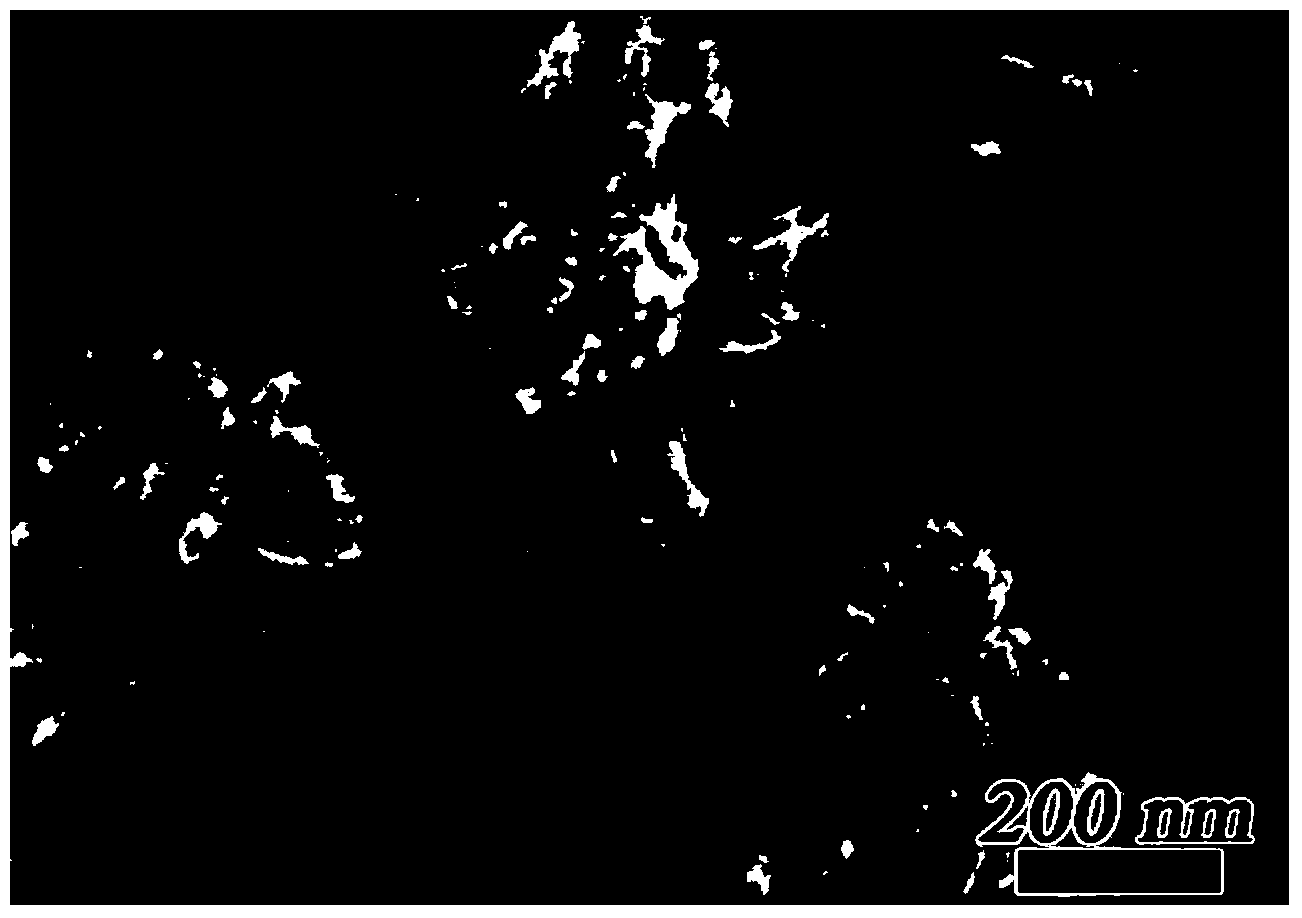

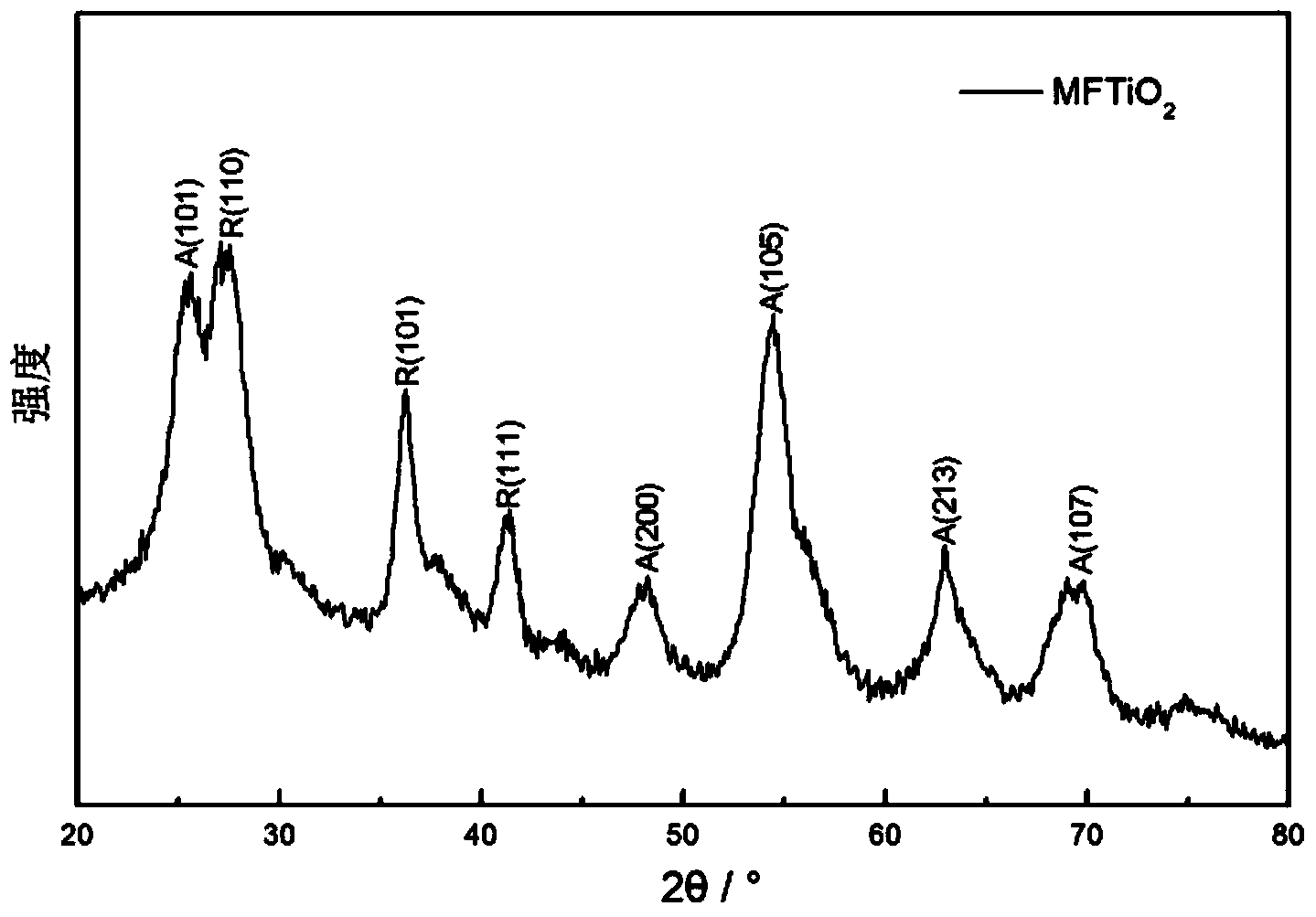

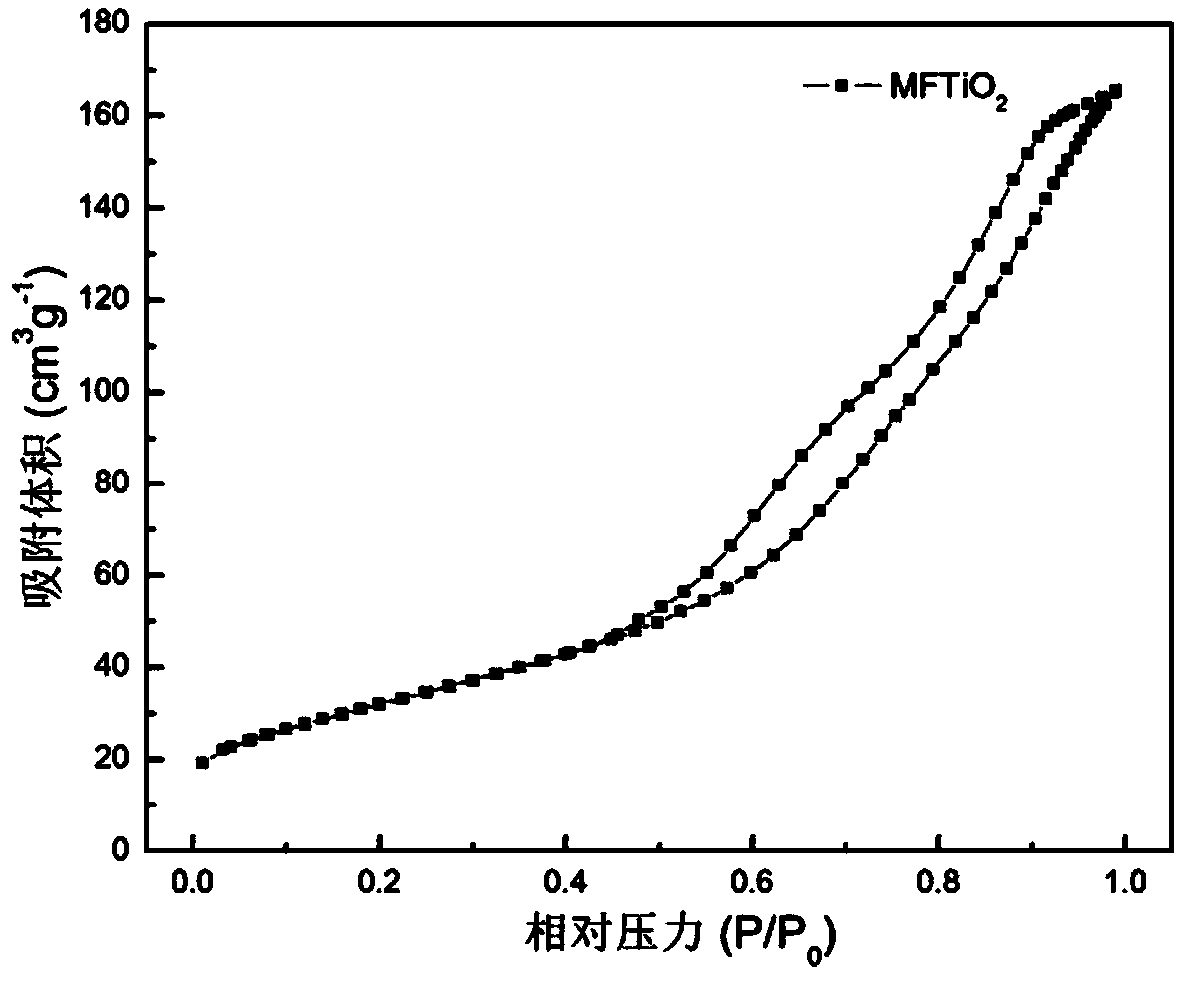

[0039] Add 1mL of 37% concentrated hydrochloric acid to 20mL of absolute ethanol, stir evenly, weigh 0.5g of P123 (8.62×10 -5 mol) was added to the above solution and stirred for 3 hours. Then, 2.96 mL (0.01 mol) of tetraisopropyl titanate was added to the above solution, and stirred for 16 hours. The entire solution system was placed in an oven at 40° C. for 12 hours, and the relative humidity was kept above 60%. Then, the obtained gel was crystallized at 80° C. for 12 hours, and the product was washed with ethanol under reflux and dried to obtain flower-shaped mesoporous titanium dioxide. In this process, under acidic conditions, the titanium source is self-assembled by nanorods under the action of surfactants to form flower-like mesoporous titanium dioxide. The size is about 3nm, and the specific surface area is 118m 2 g -1 about.

[0040] figure 1 is the scanning electron microscope image of flower-like mesoporous titanium dioxide, figure 2 is the XRD spectrum of t...

Embodiment 2

[0046] Add 3mL of 37% concentrated hydrochloric acid into 20mL of absolute ethanol, stir evenly, weigh 0.25g of P123 (4.31×10 -5 mol) was added to the above solution and stirred for 3 hours. Then, 2.96 mL (0.01 mol) of tetraisopropyl titanate was added to the above solution, and stirred for 12 hours. The entire solution system was placed in an oven at 80° C. for 24 hours, and the relative humidity was kept above 60%. Then, the obtained gel was crystallized at 90° C. for 6 hours, and the product was washed with ethanol under reflux and dried to obtain flower-shaped mesoporous titanium dioxide.

Embodiment 3

[0048] Add 5mL of 37% concentrated hydrochloric acid into 20mL of absolute ethanol, stir evenly, weigh 1.0g of P123 (1.72×10 -4 mol) was added to the above solution and stirred for 3 hours. Then, 2.96 mL (0.01 mol) of tetraisopropyl titanate was added to the above solution, and stirred for 16 hours. The entire solution system was placed in an oven at 60° C. for 12 hours, and the relative humidity was kept above 60%. Then, the obtained gel was crystallized at 80° C. for 12 hours, and the product was washed with ethanol under reflux and dried to obtain flower-shaped mesoporous titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com