Preparation method of ternary precursor

A precursor and volume technology, which is applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve the problems of narrow particle size distribution of precursors, poor circulation, stability and safety of precursors, etc., to improve charge conduction rate, The effect of uniform size and ensuring structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

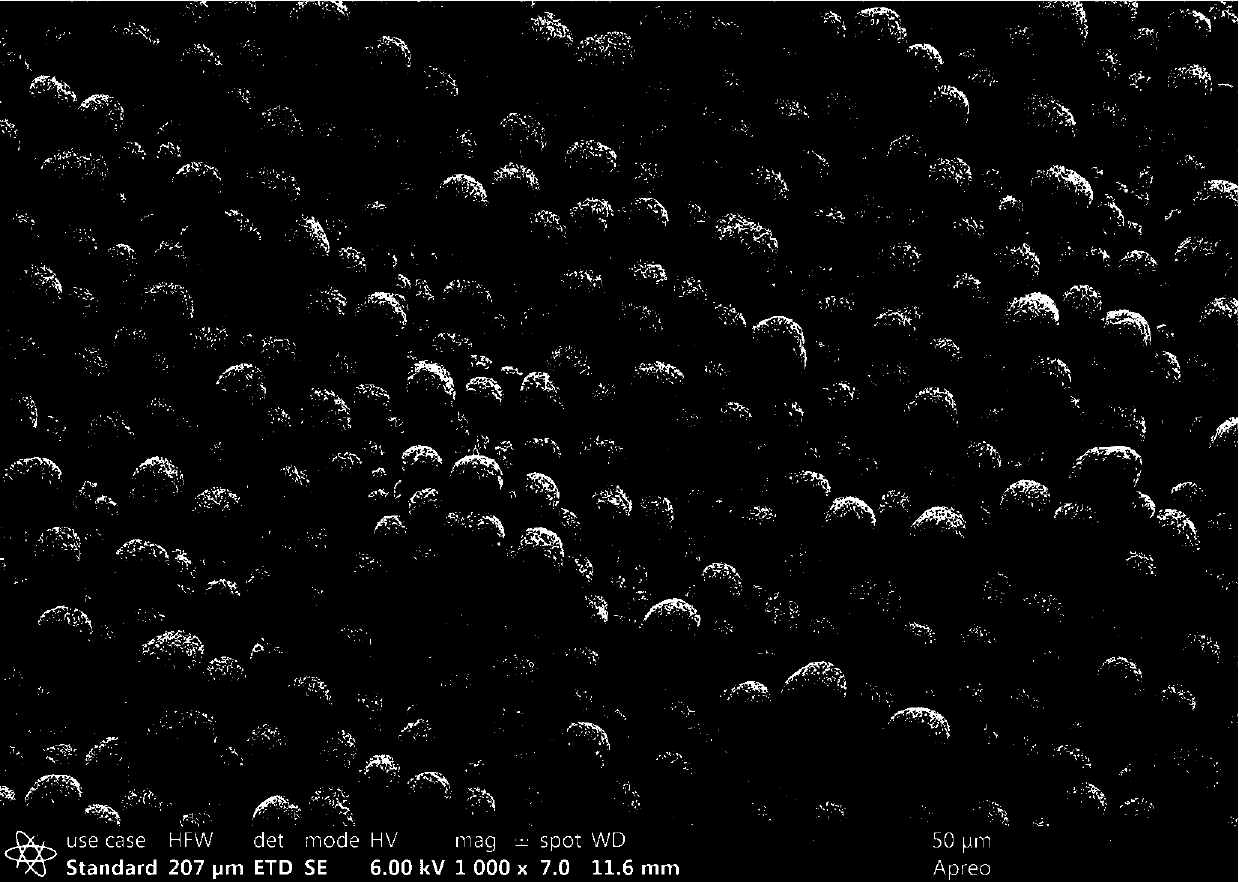

Image

Examples

Embodiment 1

[0039] A preparation method of a ternary precursor, comprising the following steps:

[0040] (1) Take 30L of 25% industrial ammonia water to obtain complexing agent aqueous solution A; uniformly mix 12kg of sodium hydroxide and hot pure water to prepare 30L of precipitant aqueous solution B; mix 15.39kg of nickel sulfate hexahydrate, 1.508kg Cobalt sulfate heptahydrate, 7.203kg manganese sulfate monohydrate (nickel-cobalt-manganese molar ratio Ni:Co:Mn=5.5:0.5:4.0) and hot pure water are fully mixed and prepared into 50L aqueous solution C;

[0041] (2) Complexing agent aqueous solution A, precipitant aqueous solution B, and aqueous solution C are kept at a constant temperature of 40°C; adjust the temperature of the constant temperature reactor to 68°C, add hot pure water to 1 / 4 of the reactor, and then add complexing agent aqueous solution A, The precipitant aqueous solution B is adjusted to the ammonia concentration of the system at 14g / L and the pH at 12.5, and is prepared ...

Embodiment 2

[0047] A preparation method of a ternary precursor, comprising the following steps:

[0048] (1) Take 25L of 25% industrial ammonia water and prepare complexing agent aqueous solution A; mix 6.6kg lithium hydroxide with hot pure water evenly to prepare 25L precipitant aqueous solution B; mix 18.447kg nickel chloride hexahydrate, 6.157kg of cobalt chloride hexahydrate, 5.131kg of manganese chloride tetrahydrate (nickel-cobalt-manganese molar ratio Ni:Co:Mn=6:2:2) are fully mixed with hot pure water to prepare 50L aqueous solution C;

[0049] (2) Keep complexing agent aqueous solution A, precipitant aqueous solution B, and aqueous solution C at a constant temperature of 35°C, control the temperature of the constant temperature reactor at 62°C, add hot pure water to 1 / 2 of the reactor, and then add complexing agent aqueous solution A, Aqueous precipitant solution B, the ammonia concentration of the control system is 13g / L, the pH is 12.3, and it is prepared as the reaction kettle...

Embodiment 3

[0054] A preparation method of a ternary precursor, comprising the following steps:

[0055] (1) Select 20L of 25% ammonia water to obtain complexing agent aqueous solution A; uniformly mix 11.2kg potassium hydroxide with hot pure water to prepare 20L precipitant aqueous solution B; mix 14.128kg nickel nitrate hexahydrate, 5.655kg Cobalt nitrate, 7.319 kg of manganese nitrate tetrahydrate (nickel-cobalt-manganese molar ratio Ni:Co:Mn=5:2:3) and deionized water were fully mixed and evenly adjusted to 120L to prepare aqueous solution C;

[0056] (2) Complexing agent aqueous solution A, precipitating agent aqueous solution B, and aqueous solution C are kept at a constant temperature of 38°C, and the temperature of the constant temperature reactor is controlled at 60°C. Add hot pure water to 1 / 4 of the reactor, and then add complexing agent aqueous solution A, The precipitant aqueous solution B is adjusted to the ammonia concentration of the system at 13.5g / L and the pH at 12.4, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com