Lithium-ion battery with pneumatic anti-gas-expansion automatic liquid replenishing device

An automatic liquid replenishment device and lithium-ion battery technology, applied in the direction of battery components, electrolyte storage battery manufacturing, non-aqueous electrolyte storage battery, etc., can solve the problems of large electrolyte consumption, restriction of practical application, safety performance cannot be guaranteed, etc. Achieve the effects of preventing safety accidents, improving safety performance, ensuring cycle performance and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

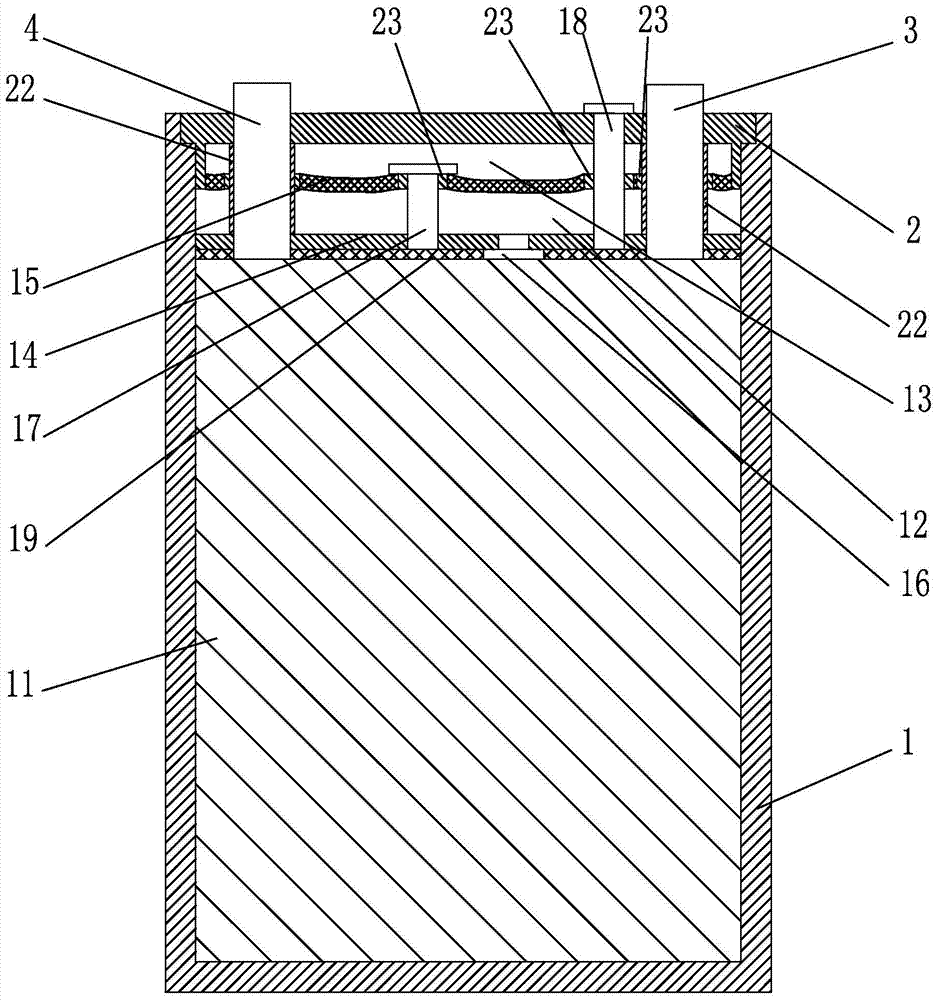

[0021] Such as figure 1 Shown: a lithium-ion battery equipped with a pneumatic anti-flatulence automatic liquid replenishment device, including a battery case 1, a battery top cover plate 2, a positive pole 3, a negative pole 4, and a positive pole inside the battery shell. The battery cell is composed of a negative electrode sheet, a diaphragm and an electrolyte. The inside of the battery case is divided into three chambers. The three chambers are respectively the cell chamber 11, the spare electrolyte chamber 12 and the A gas buffer chamber 13, the spare electrolyte chamber is equipped with a spare electrolyte, and the spare electrolyte in the spare electrolyte chamber contains a gas scavenger. An insulating sleeve 22 is provided on the outer wall of the positive pole column and the outer wall of the negative pole pole located between the spare electrolyte chamber and the gas buffer chamber. A fixed partition 14 is used to separate the cell chamber and the spare electrolyte...

Embodiment 2

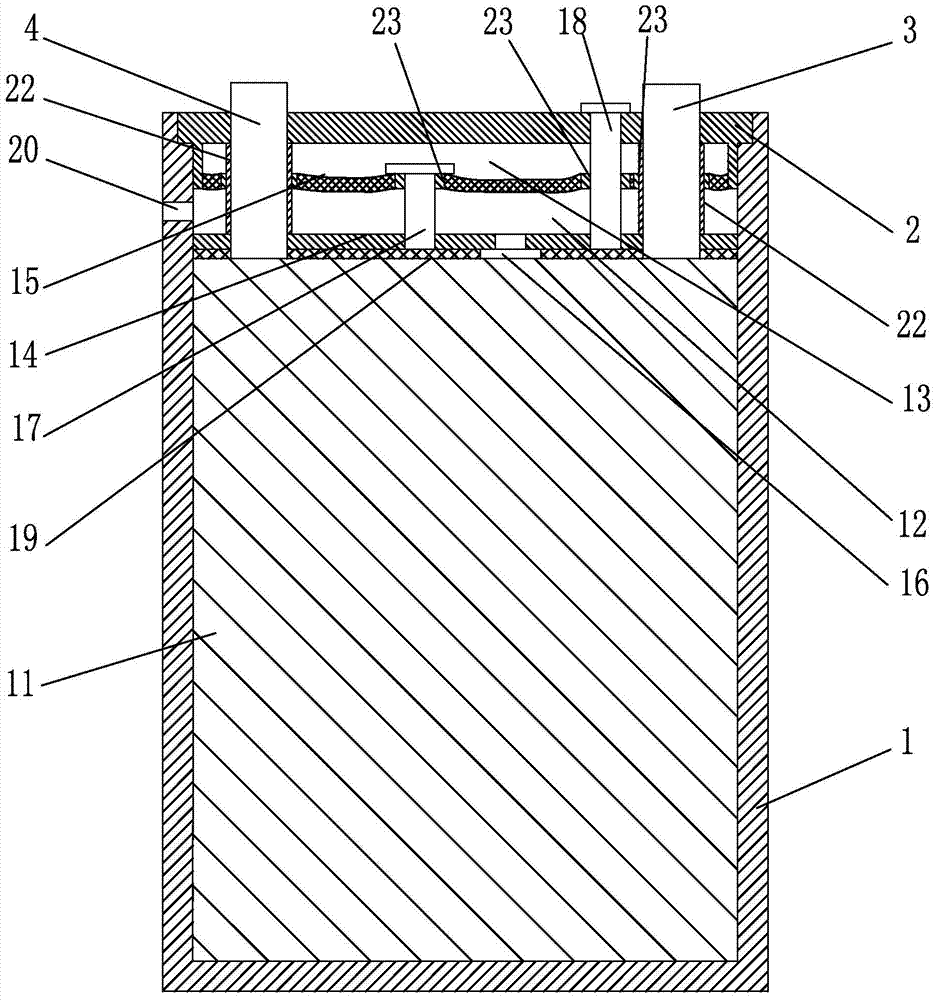

[0023] Such as figure 2 Shown: a lithium-ion battery equipped with a pneumatic anti-flatulence automatic liquid replenishment device, including a battery case, a battery top cover, a positive pole, a negative pole, and a positive pole piece and a negative pole piece arranged inside the battery shell. , diaphragm and electrolyte, the inside of the battery case is divided into three chambers, and the three chambers are from the top of the battery from bottom to top, respectively, the cell chamber, the spare electrolyte chamber and the gas buffer chamber. A standby electrolyte is housed in the standby electrolyte cavity, and the standby electrolyte in the standby electrolyte cavity contains a gas eliminating agent. An insulating sleeve is provided on the outer wall of the positive pole column and the outer wall of the negative pole pole located between the spare electrolyte chamber and the gas buffer chamber. The part that separates the cell chamber and the spare electrolyte ch...

Embodiment 3

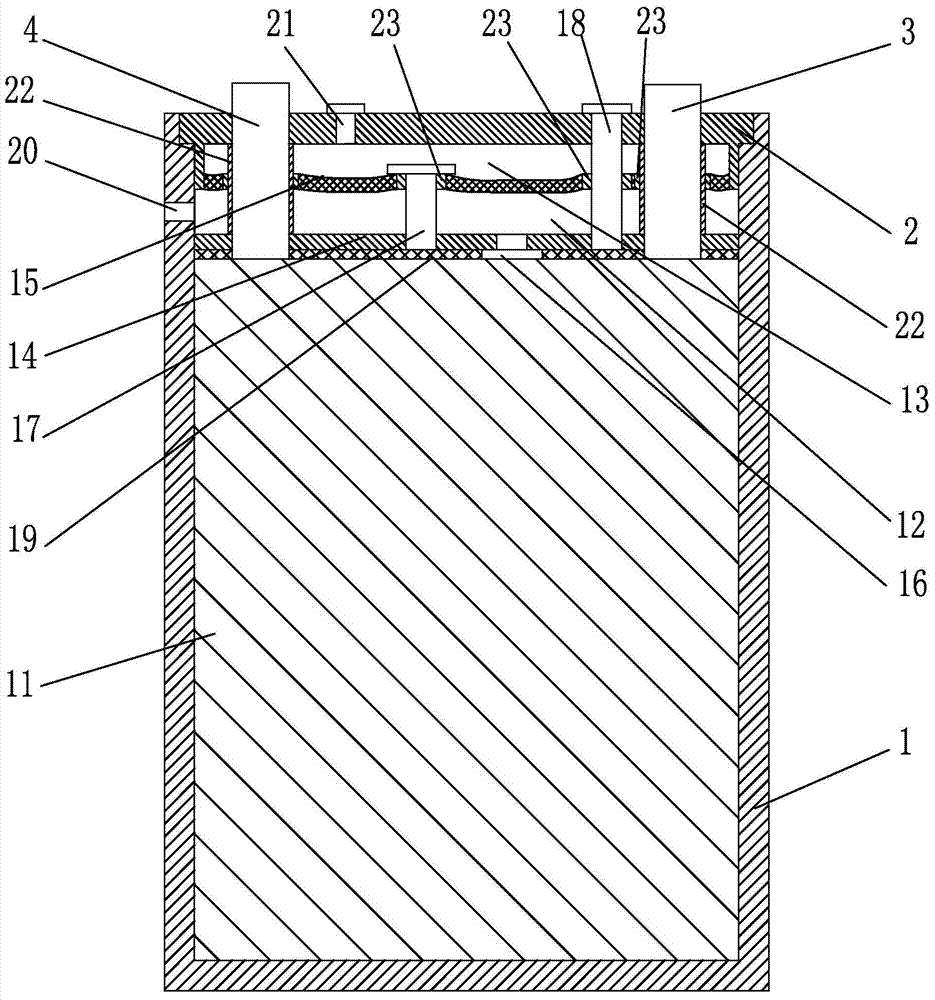

[0026] Such as image 3 Shown: a lithium-ion battery equipped with a pneumatic anti-flatulence automatic liquid replenishment device, including a battery case, a battery top cover, a positive pole, a negative pole, and a positive pole piece and a negative pole piece arranged inside the battery shell. , diaphragm and electrolyte, the inside of the battery case is divided into three chambers, and the three chambers are from the top of the battery from bottom to top, respectively, the cell chamber, the spare electrolyte chamber and the gas buffer chamber. A standby electrolyte is housed in the standby electrolyte cavity, and the standby electrolyte in the standby electrolyte cavity contains a gas eliminating agent. An insulating sleeve is provided on the outer wall of the positive pole column and the outer wall of the negative pole pole located between the spare electrolyte chamber and the gas buffer chamber. The part that separates the cell chamber and the spare electrolyte cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com