High-voltage lithium cobalt positive electrode material and preparation method and application thereof

A positive electrode material, lithium cobalt oxide technology, applied in the field of high-voltage lithium cobalt oxide positive electrode material and its preparation, can solve the problems of doping, instability, high manganese doping content, etc., and achieve simple preparation method and process, good structure and stability Sexuality and controllable effect of the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

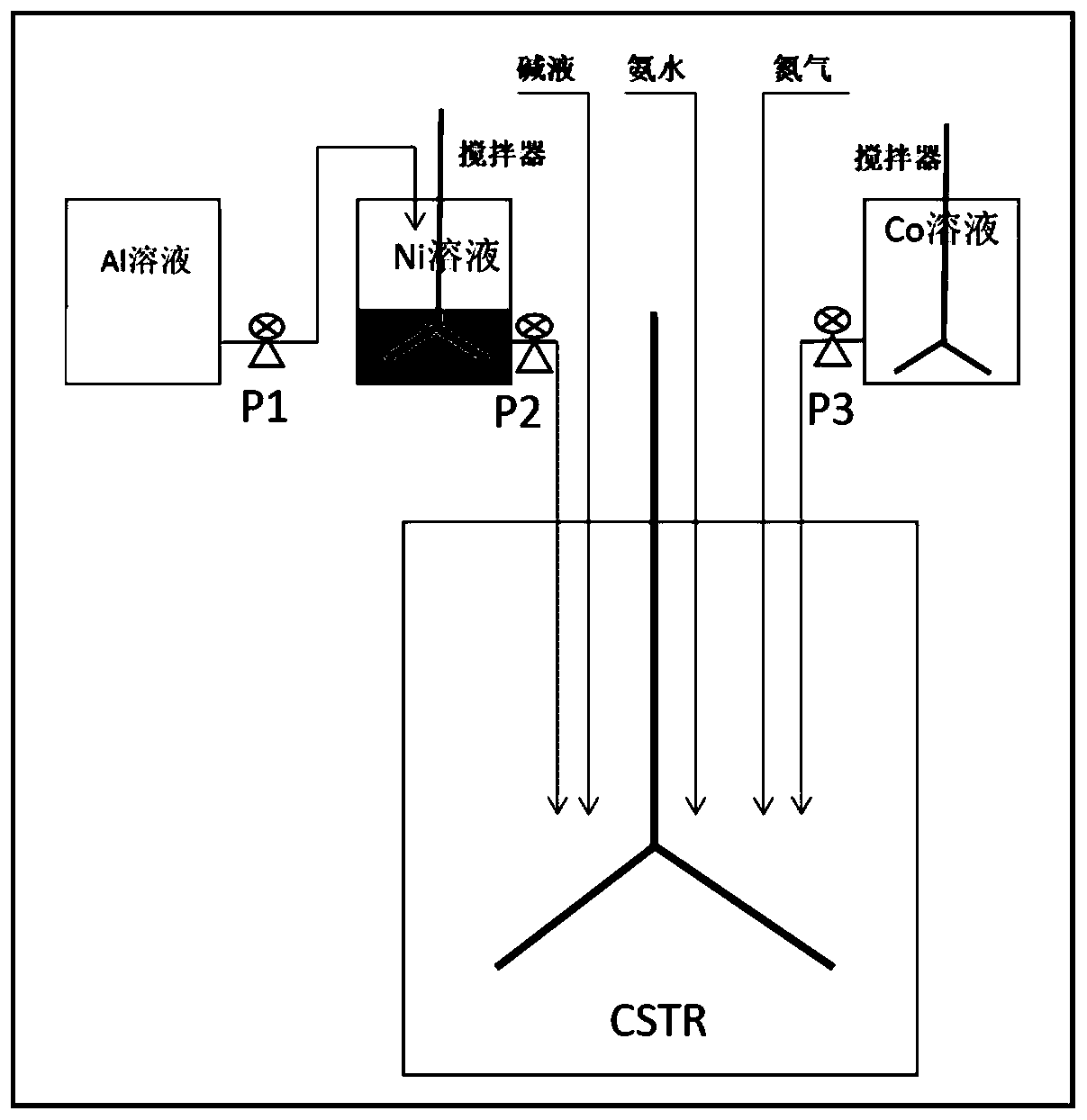

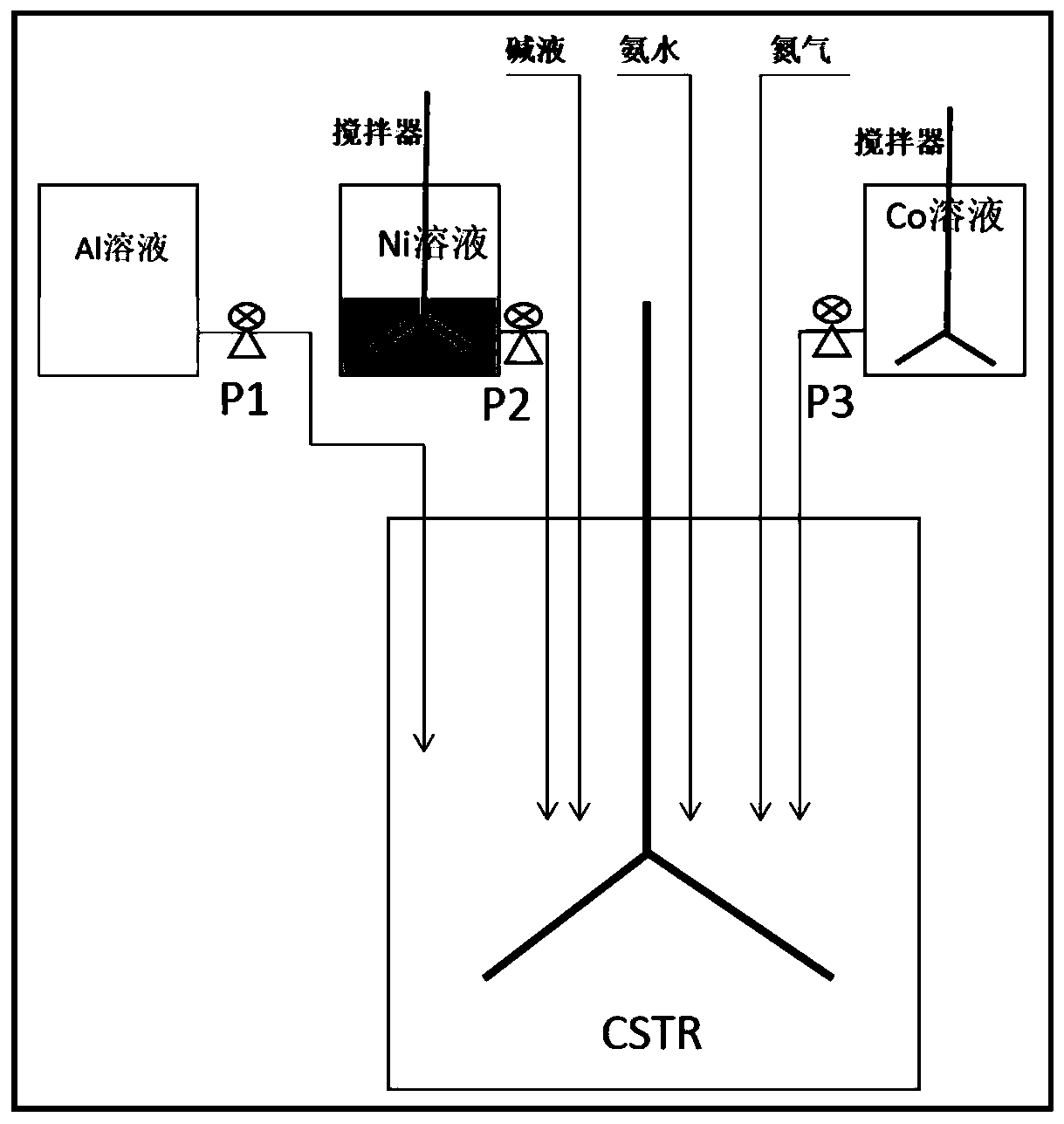

[0064] The preparation concentration is 200L of cobalt nitrate solution of 0.4mol / L, the preparation concentration is 6.25L of nickel nitrate solution of 0.2mol / L, the preparation concentration is 8.33L of aluminum nitrate of 0.2mol / L, do precipitant with 30% liquid caustic soda, with 25% analytical pure ammonia as complexing agent. Wherein, cobalt nitrate, aluminum nitrate, nickel nitrate, sodium hydroxide alkali solution and complexing agent are respectively put into different containers, wherein cobalt nitrate solution and nickel nitrate solution are respectively put into containers with stirring. refer to figure 1 At the same time, open the liquid inlet metering pump, the aluminum nitrate solution flows into the nickel nitrate solution with stirring at a flow rate of 167mL / h, the nickel nitrate solution flows into the reactor at a flow rate of 292mL / h, and the cobalt nitrate solution flows into the reactor at a flow rate of 4L / h Reactor, nitrogen gas is passed into the re...

Embodiment 2

[0072] The preparation concentration is 80L of cobalt sulfate solution of 1mol / L, the preparation concentration is 10.83L of nickel sulfate solution of 0.1mol / L, the preparation concentration is 33.3L of aluminum nitrate of 0.05mol / L, do precipitation agent with 30% liquid caustic soda, with 25 % analytically pure ammonia as complexing agent. Among them, the cobalt sulfate solution, the aluminum nitrate solution, the nickel sulfate solution, the sodium hydroxide alkali solution and the complexing agent are put into different containers respectively, wherein the cobalt sulfate solution and the nickel sulfate solution are respectively put into a container with stirring. At the same time, turn on the liquid inlet metering pump, the aluminum nitrate solution flows into the nickel sulfate solution with stirring at a flow rate of 832.5mL / h, the nickel sulfate solution flows into the reactor at a flow rate of 1.1L / h, and the cobalt sulfate solution flows at a flow rate of 2L / h It flo...

Embodiment 3

[0076] Prepare 100L of cobalt chloride solution with a concentration of 0.8mol / L, 10.47L of nickel chloride solution with a concentration of 0.2mol / L, 8.38L of aluminum chloride with a concentration of 0.2mol / L, and use 30% liquid caustic for precipitation As a complexing agent, use 25% analytically pure ammonia water as a complexing agent. Among them, cobalt chloride solution, aluminum chloride solution, nickel chloride solution, sodium hydroxide alkali solution and complexing agent are put into different containers respectively, wherein cobalt chloride and nickel chloride solution are put into a container with stirring middle. At the same time, open the liquid inlet metering pump, the aluminum chloride solution flows into the nickel chloride solution with stirring according to the flow rate of 167.6mL / h, the nickel chloride solution flows into the reactor at a flow rate of 377mL / h, and the cobalt chloride solution flows into the reactor at a flow rate of 2L / h. The flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com