Porous metal oxide-carbon composite thin film electrode and preparation method thereof

A porous metal and thin-film electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor conductivity, large volume expansion, and poor cycle life, improve specific capacity and rate characteristics, and shorten lithium ion migration path. , the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

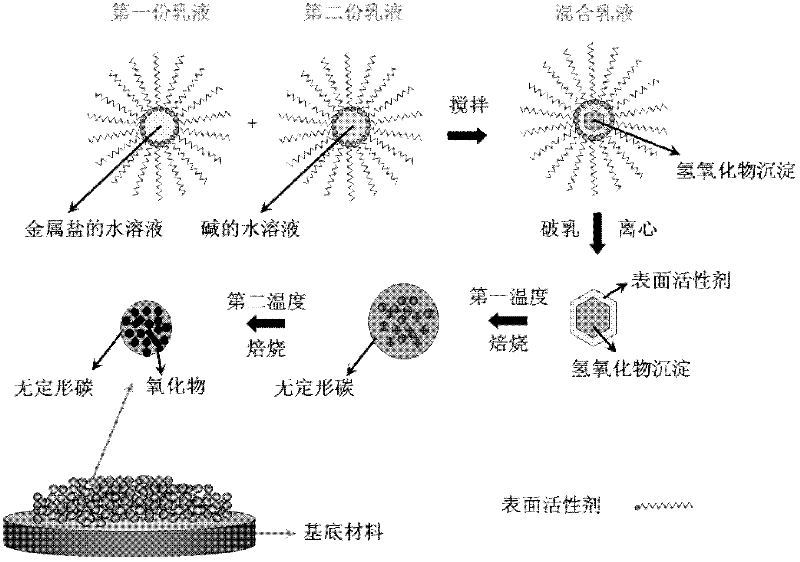

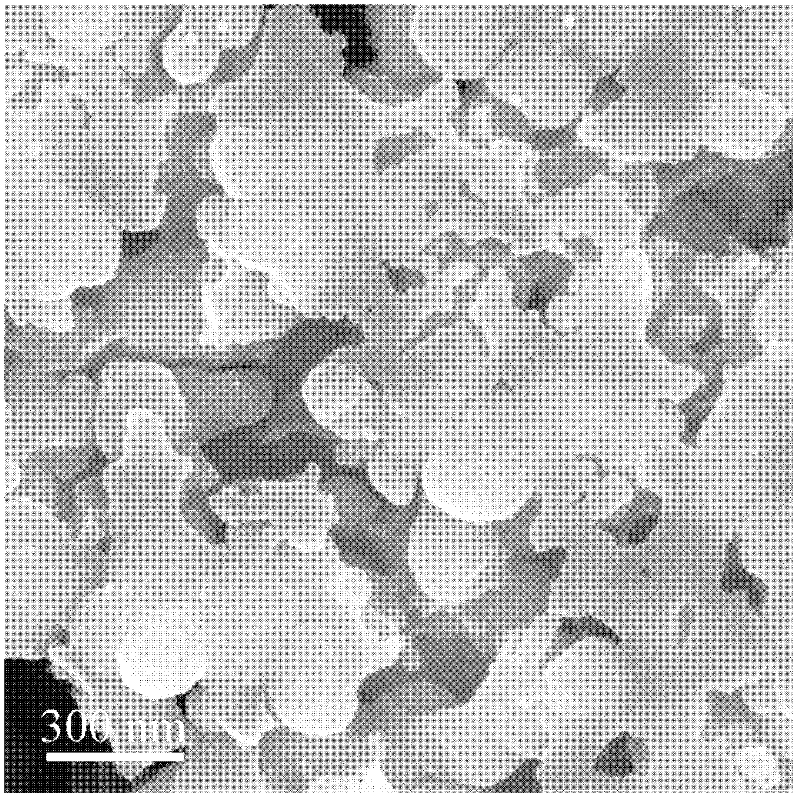

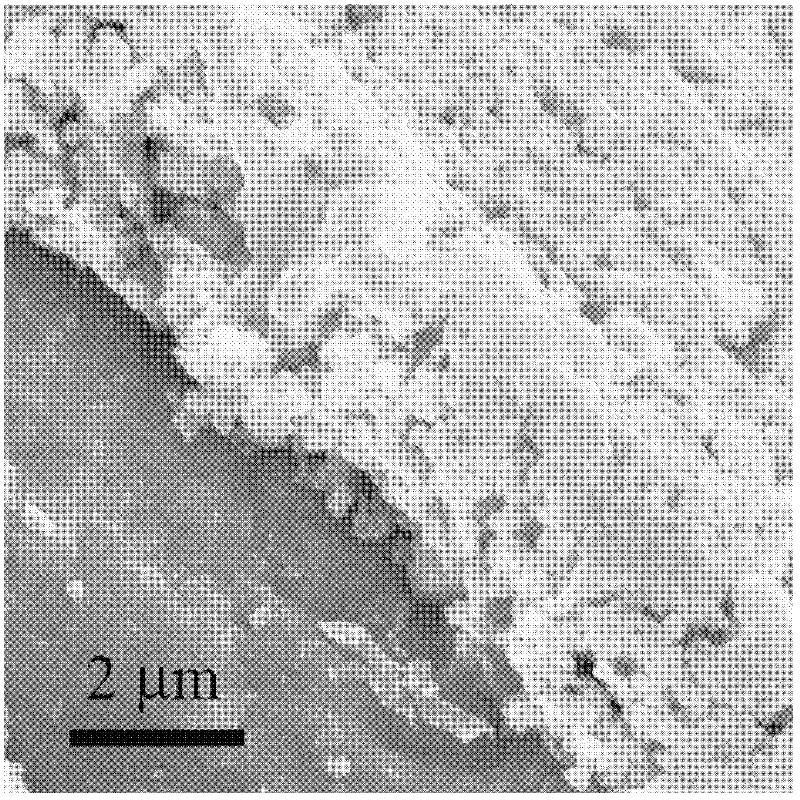

[0024] Take the cobalt nitrate aqueous solution that concentration is 0.1mol / L and the NH that concentration is 5 mass % 4 The volume of each 1 part of OH aqueous solution was added successively to the above two parts of aqueous solutions respectively 3 parts of volumes of Triton X-100 (purchased from Xilong Chemical Co., Ltd., TX-100), 2 parts of volumes of normal Butanol and 40 volumes of cyclohexane were stirred at a speed of 1000 rpm for 30 minutes to obtain two water-in-oil emulsions. Mix the two water-in-oil emulsions, stir at 2000 rpm for 15 minutes, then let stand in a water bath at 40°C for 32 hours, add 10 volumes of absolute ethanol to break the emulsion, and centrifuge at 4000 rpm for 8 Minutes, and directly and uniformly coat the centrifugal sediment on one surface of the copper foil, the amount of the centrifugal sediment coated on the copper foil is 38mg / cm 2 . The copper foil coated with the precipitate was baked at 400°C for 1 hour under a nitrogen atmospher...

Embodiment 2

[0028] Take the ferric nitrate aqueous solution that concentration is 0.05mol / L and the NH that concentration is 2.5 mass % 4The volume of each 1 part of OH aqueous solution was respectively added to the above two parts of aqueous solutions successively by adding 2 parts of volume of Triton X-100 (purchased from Xilong Chemical Co., Ltd. Butanol and 20 volumes of cyclohexane were stirred at a speed of 2000 rpm for 15 minutes to obtain two water-in-oil emulsions. Mix the two water-in-oil emulsions, stir at 1000 rpm for 30 minutes, let stand in a water bath at 50°C for 24 hours, add 8 volumes of absolute ethanol to break the emulsion, and centrifuge at 3000 rpm for 10 Minutes, and directly and uniformly coat the centrifugal sediment on one surface of the copper foil, the amount of the centrifugal sediment coated on the copper foil is 8mg / cm 2 . The copper foil coated with the precipitate was calcined at 450°C for 0.5 hours in a nitrogen atmosphere, and then calcined at 300°C f...

Embodiment 3

[0030] Take the nickel nitrate aqueous solution that concentration is 0.2mol / L and the NH that concentration is 12 mass % 4 Each 1 part volume of the OH aqueous solution was added successively to the above two parts of aqueous solutions by 2.5 parts by volume of Triton X-100 (purchased from Xilong Chemical Co., Ltd., TX-100), 0.85 parts by volume of normal Butanol and 60 volumes of cyclohexane were stirred at a speed of 1500 rpm for 20 minutes to obtain two water-in-oil emulsions. Mix the two water-in-oil emulsions, stir at 1500 rpm for 20 minutes, then let stand in a water bath at 60°C for 48 hours, add 12 volumes of absolute ethanol to break the emulsion, and centrifuge at 5000 rpm for 5 Minutes, and directly and evenly coat the centrifugal sediment on one surface of the copper foil, the amount of the centrifugal sediment coated on the copper foil is 50mg / cm 2 . The copper foil coated with the precipitate was calcined at 350°C for 3 hours in a nitrogen atmosphere, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com