Pressure chamber for in-situ generation and triaxial test of marine gas hydrate and using method thereof

An in-situ generation, triaxial experiment technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem that it is difficult to apply hydrate in-situ generation and triaxial experiments, and cannot achieve horizontal gas. Infiltration, long hydrate synthesis time and other problems, to achieve the effect of improving temperature uniformity and temperature control efficiency, wide practicability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

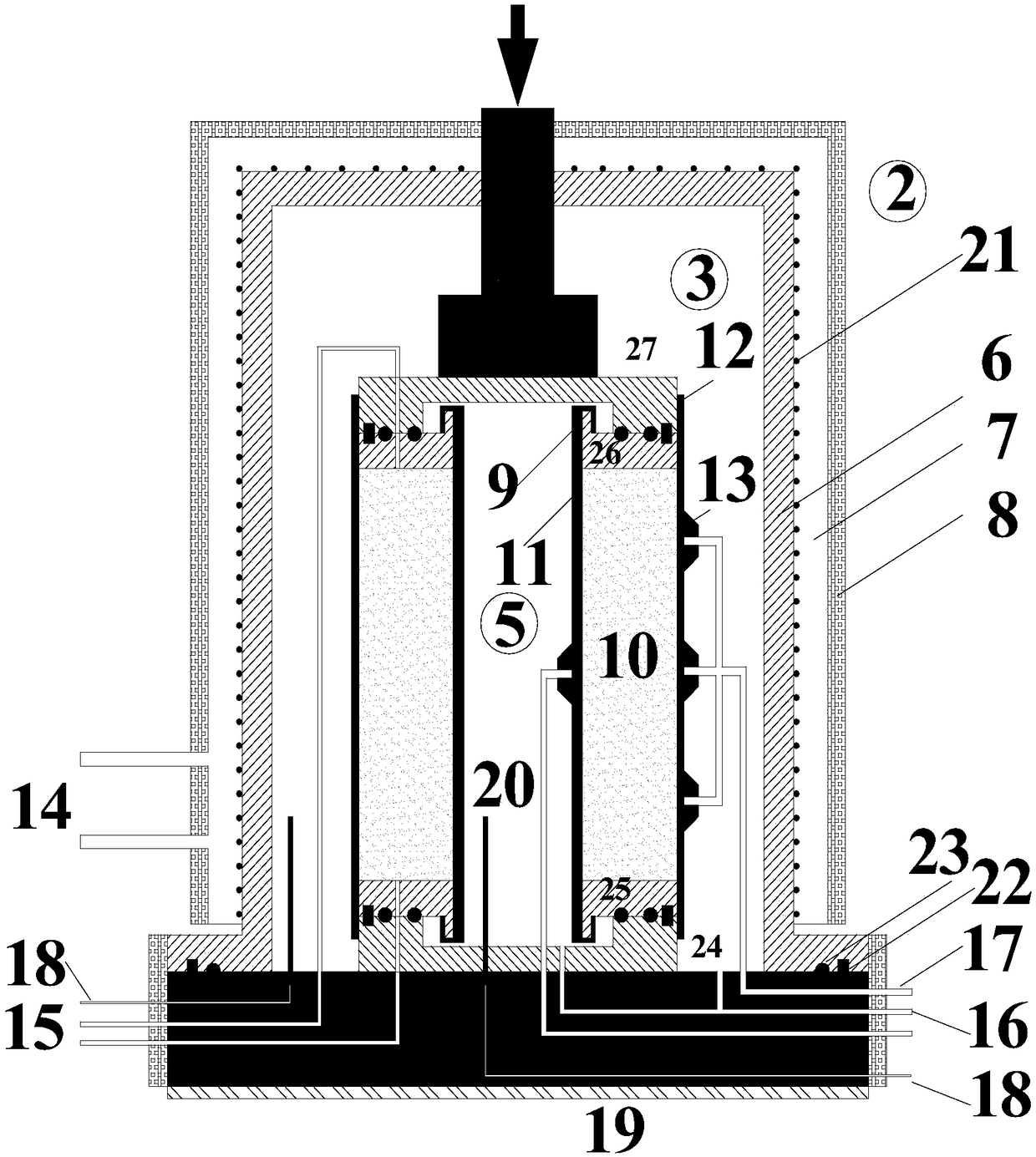

[0024] The pressure chamber for the in-situ formation of sea hydrate and the triaxial experiment of the present invention mainly consists of a base 1, a sleeve 2 and a piston rod 4. The sleeve 2 includes a pressure chamber 6 from the inside to the outside, a refrigerant circulation Cavity 7 and insulation layer 8; the base 1 and the sleeve 2 are sealed by bolts 22 and sealing rings 23, the bottom surface of the base 1 is provided with an insulation layer 19, and the base 1 is provided with a The sleeve 2 and the temperature sensor 20 connected to the signal wire 18 in the hollow cylindrical sample 10 . The upper and lower fixing blocks for fixing the hollow cylindrical sample 10 are arranged inside the sleeve 2. The upper fixing block includes an upper connecting block 26, an upper main spacer 27 that is buckled stepwise with the upper connecting bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com