Composite modified lithium ion battery cathode material and preparation method thereof

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unstable cycle performance, high hygroscopicity, and reduced discharge specific capacity or energy density of materials to improve cycle performance. and stability, the effect of avoiding decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add Al2O3 to the glucose solution and stir at a high speed for 30 minutes, then perform ultrasonication for 10 minutes, and then perform high-speed stirring and ultrasonic circulation for 3 to 5 times, and mix well to form a uniform mixed solution; the positive electrode material LiNi 0.8 co 0.15 al 0.05 o 2 Add it into the above mixture under stirring conditions, so that the coating material is uniformly coated on the surface of the active material particles; dry the mixture for 4-8 hours, and calcinate the dried solid material at 500 ° C for 6 hours, then cool and pulverize and sieving to obtain the modified cathode material.

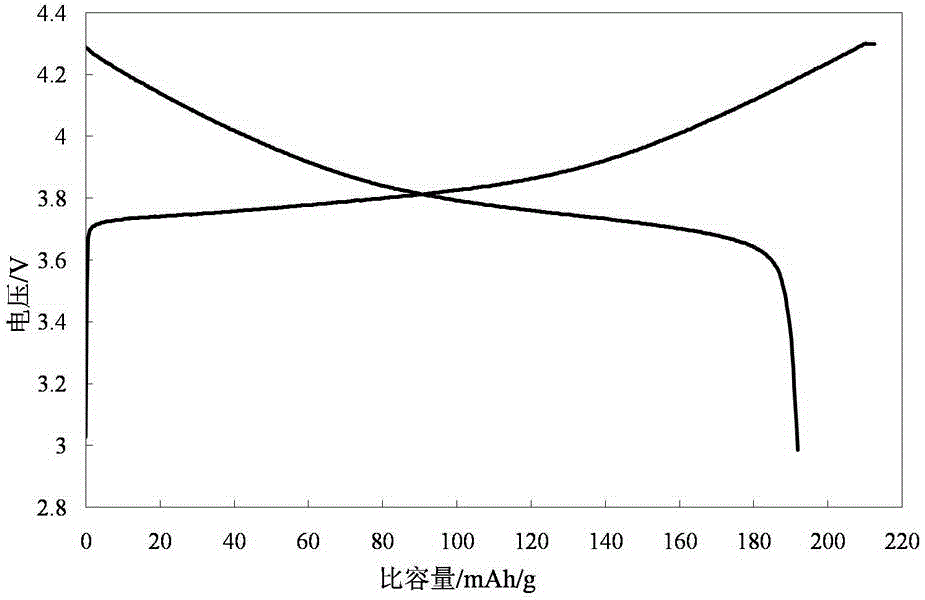

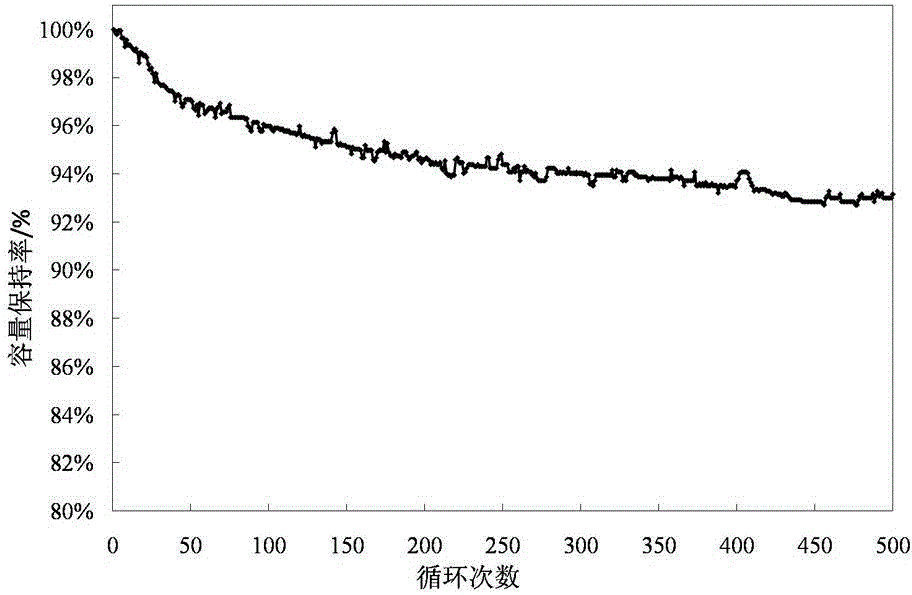

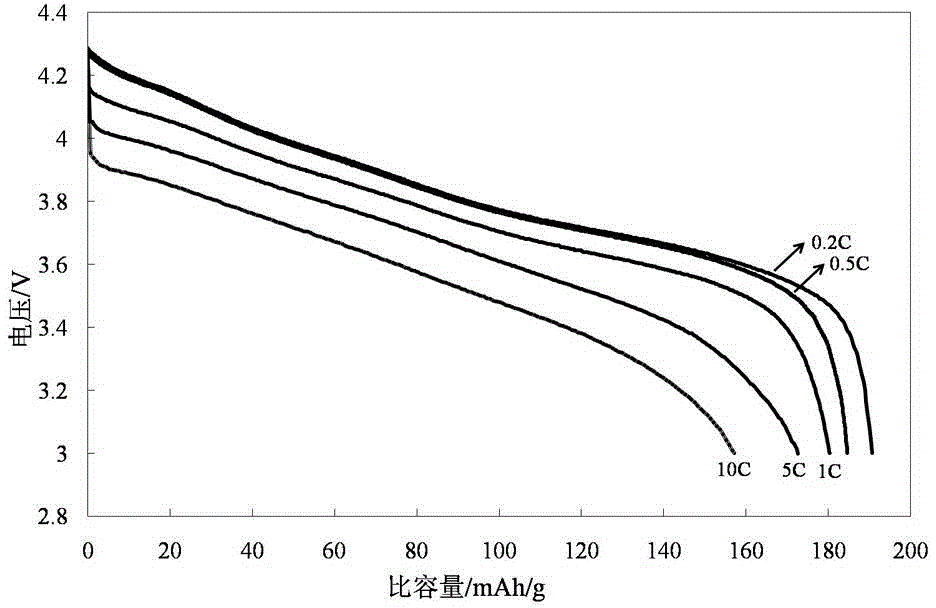

[0028] The electrochemical performance test of the material is tested at 25°C with the blue battery test system. The rate performance test conditions: the test voltage range is 3V to 4.3V, 0.2C charge and discharge once, 0.2C charge 0.5C / 1C / 5C / 10C Each discharge once; cycle performance test conditions: the test voltage range is 3V ~ 4.3V, ch...

Embodiment 2

[0030] Magnesium oxide was added to the starch solution and stirred at high speed for 30 minutes, and then ultrasonicated for 10 minutes, followed by high-speed stirring and ultrasonic cycle for 3 to 5 times, and mixed evenly to form a uniform mixed solution; the positive electrode material LiNi 0.8 co 0.15 al 0.05 o 2 Add it into the above mixed liquid under the condition of stirring, so that the coating material is evenly coated on the surface of the active material particles; dry the mixture for 4-8 hours, calcinate the dried solid material at 600 ° C for 5 hours, cool and pulverize and sieving to obtain the modified cathode material.

Embodiment 3

[0032] Add titanium dioxide and graphite to anhydrous ethanol and stir at high speed for 30 minutes, then perform ultrasonication for 10 minutes, successively high-speed stirring and ultrasonic circulation 3 to 5 times, and mix uniformly to form a uniform mixed solution; the positive electrode material LiNi 0.8 co 0.15 al 0.05 o 2 Add it into the above mixed liquid under the condition of stirring, so that the coating material is evenly coated on the surface of the active material particles; dry the mixture for 4-8 hours, calcinate the dried solid material at 600 ° C for 5 hours, cool and pulverize and sieving to obtain the modified cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com