Method for preparing three-dimensional hole carbon/nano NiO composite

A kind of composite material and nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of material loss of activity, increased volume expansion, low conductivity, etc., to improve conductivity and Effects of stability, damage prevention, and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with specific embodiment, further illustrate the present invention.

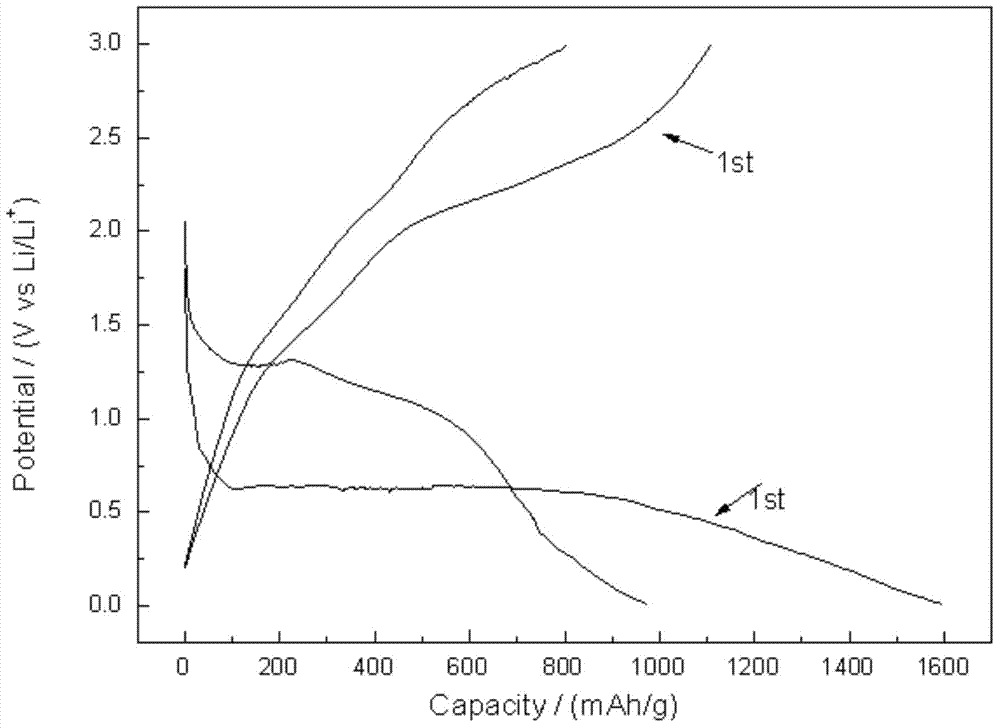

[0061] A method for preparing a three-dimensional porous carbon / nano-NiO composite material, characterized in that the method comprises the following steps:

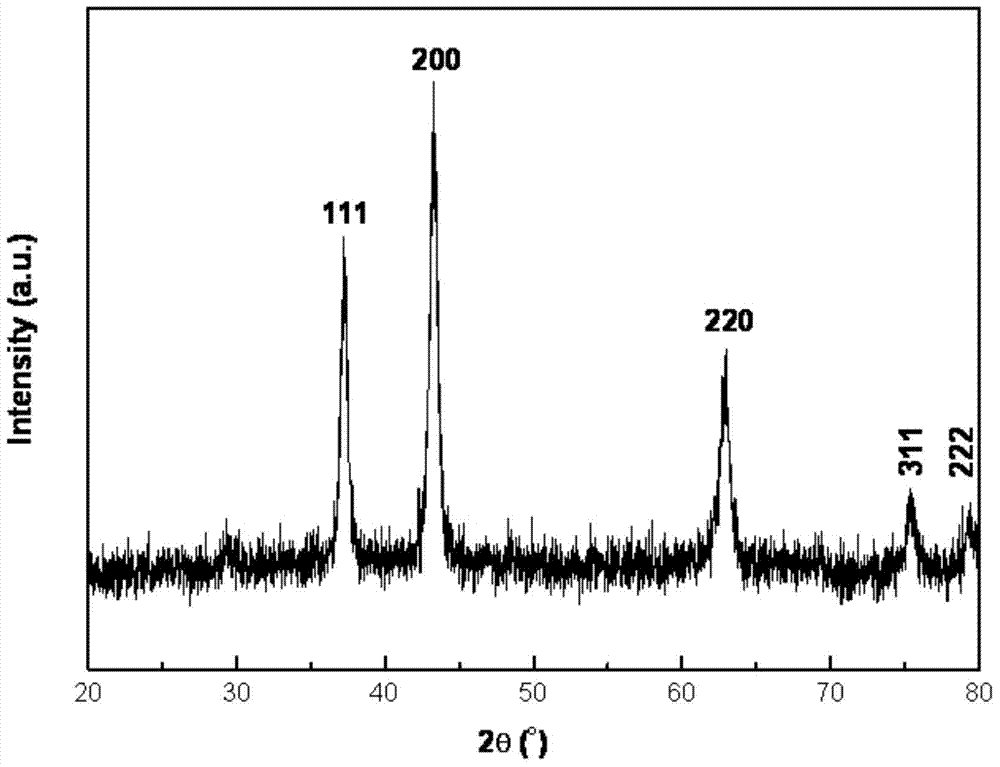

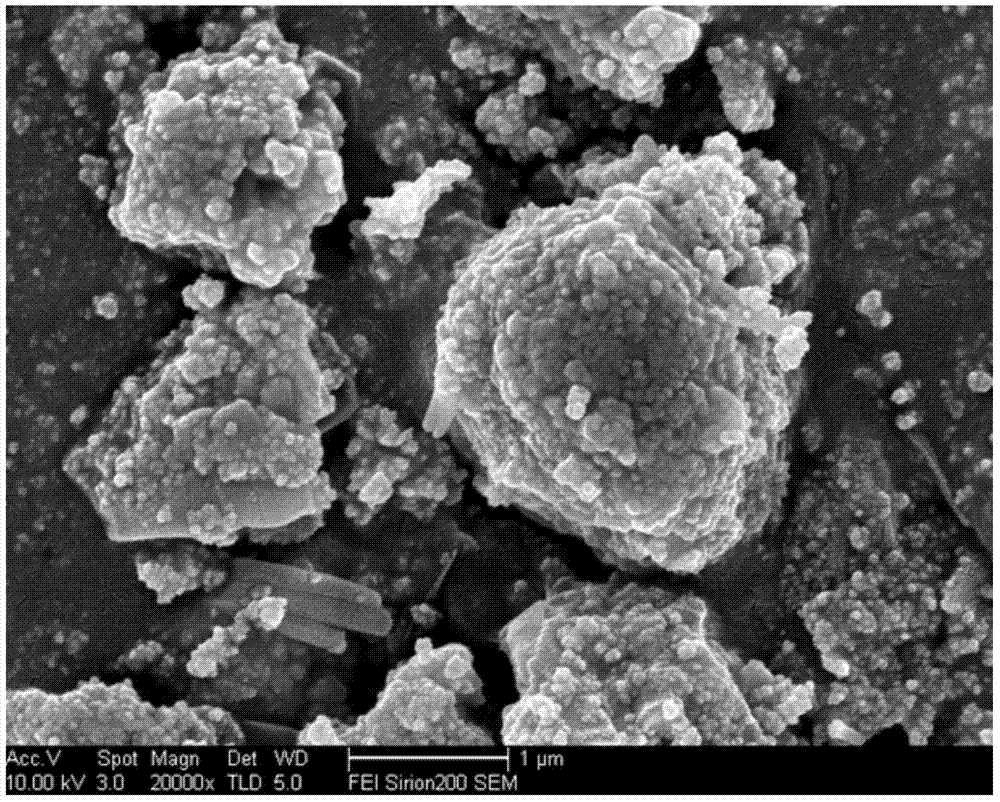

[0062] Step 1, preparation of nano-NiO

[0063] Nano-NiO powder was prepared by sol-gel method, with nickel acetate as nickel source, citric acid as chelating agent, the concentration of nickel acetate was 0.6mol / L, the molar ratio of nickel acetate to citric acid was 1:1, dissolved in 50ml ethylene glycol, using 40% HNO 3 The pH of the solution was adjusted to 1, the temperature was raised to 80°C, and the heating rate was 5°C / min, the solution was evaporated to 1 / 3 of the total amount to obtain a green transparent sol, and vacuum-dried at 130°C for 12 hours to obtain a green xerogel, which was transferred to Baking at 600-800°C for 2-5 hours in a muffle furnace. Grinding to obtain nanometer NiO powder.

[0064] Step 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com