Method for synthesizing positive material nano lithium manganese phosphate of lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, circuits, electrical components, etc., to achieve the effects of easy control of process parameters, expansion of research work, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

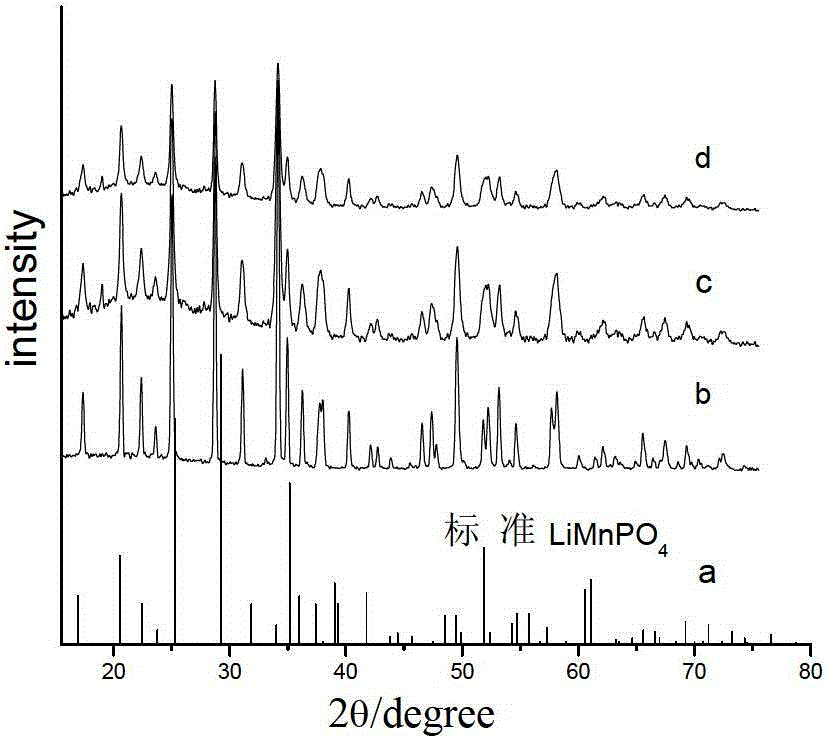

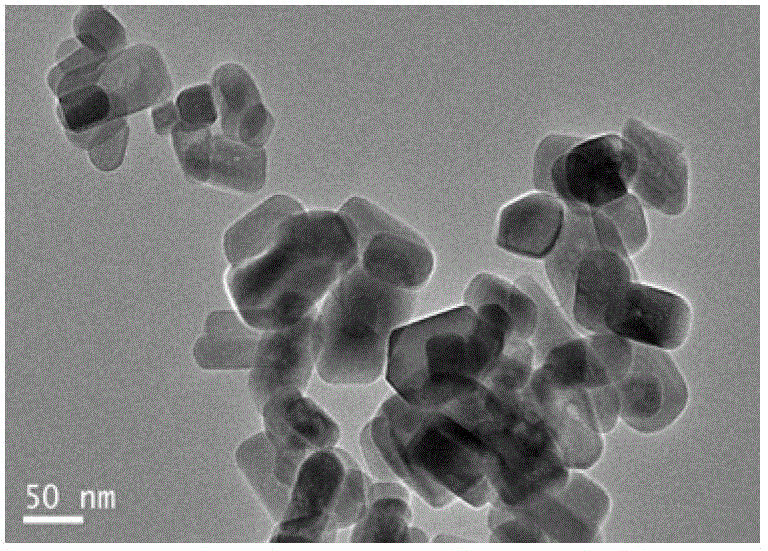

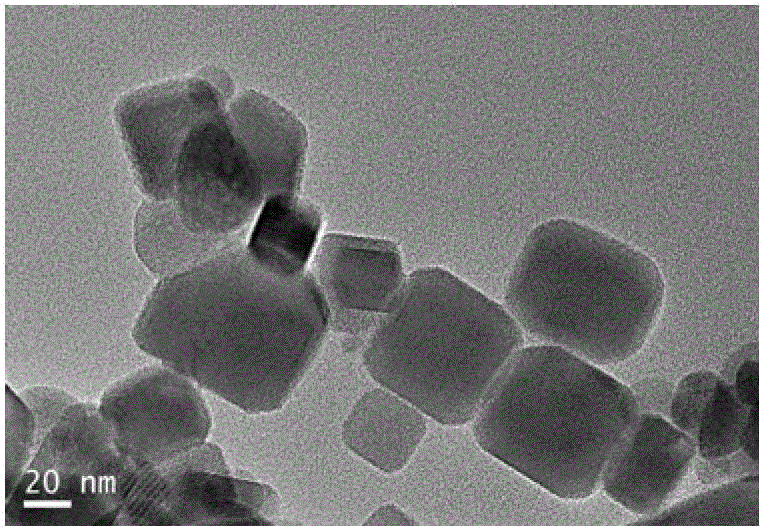

Image

Examples

Embodiment 1

[0026] (1) Dissolve 2mmol of manganese nitrate, 2.2mmol of lithium nitrate and 2mmol of phosphoric acid in 7mL of industrial alcohol, and stir to dissolve;

[0027] (2) Then pour the phosphoric acid solution directly into the lithium nitrate solution, and stir and mix evenly;

[0028] (3) Then pour the manganese nitrate solution into the mixed solution obtained in step (2), and continue to stir evenly;

[0029] (4) Take another 12 mL polyethylene glycol 400 and pour it into the mixed solution obtained in step (3), mix and stir evenly;

[0030] (5) Pour the solution obtained in step (4) into a 50mL polytetrafluoroethylene autoclave, seal, heat up to 150°C at a rate of 2°C / min, heat at a constant temperature for 12h, cool to room temperature naturally, and centrifuge the product. Wash with deionized water and ethanol, filter and dry.

Embodiment 2

[0032] (1) Dissolve 2mmol of manganese acetate, 2mmol of lithium acetate and 2mmol of phosphoric acid in 8mL of absolute ethanol, and stir to dissolve;

[0033] (2) Then, add lithium acetate solution dropwise to the phosphoric acid solution, and stir and mix evenly;

[0034] (3) Next, add the manganese acetate solution dropwise to the mixed solution obtained in step (2), and continue to stir evenly;

[0035] (4) Add octadecylamine to the mixture obtained in step (3), mix and stir uniformly, the total volume of the obtained solution is 36 mL;

[0036] (5) Pour the solution obtained in step (4) into a 50mL polytetrafluoroethylene autoclave, seal, heat up to 155°C at a rate of 3°C / min, heat at a constant temperature for 15h, cool to room temperature naturally, and centrifuge the product. Wash with deionized water and ethanol, filter and dry.

Embodiment 3

[0038] (1) Dissolve 2mmol of manganese acetate, 2.4mmol of lithium nitrate and 2mmol of phosphoric acid in 7mL of absolute ethanol, and stir to dissolve;

[0039] (2) Then add the phosphoric acid solution dropwise to the lithium nitrate solution, and stir and mix evenly;

[0040] (3) Next, pour the manganese acetate solution into the mixed solution obtained in step (2), and continue to stir evenly;

[0041] (4) Take another 14 mL of oleic acid and pour into the mixed solution obtained in step (3), mix and stir evenly;

[0042] (5) Pour the solution obtained in step (4) into a 50mL polytetrafluoroethylene autoclave, seal, heat up to 145°C at a rate of 3°C / min, and heat at a constant temperature for 10 hours; cool to room temperature naturally, and centrifuge the product. Wash with deionized water and ethanol, filter and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com