Bonding method for non-woven fabric handle of packaging box

A bonding method, non-woven technology, applied in packaging, transportation and packaging, box making operations, etc., can solve the problems of unreliable fixing method, uneven force on cardboard, easy to fall off, etc., to ensure strength and increase resistance. Area of force, effect of preventing tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

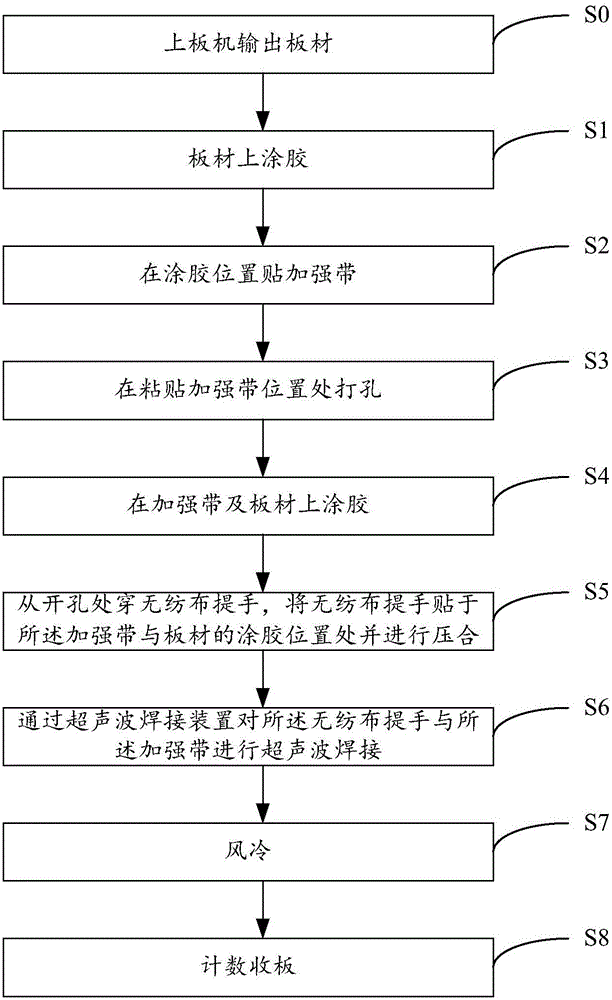

[0020] Such as figure 1 As shown, the present invention discloses a method for bonding non-woven fabric handles of packaging boxes, including the following steps: S0: plate loading machine conveys the plate; S1: two positions of pre-installed handles on the upper panel of the packaging box Glue at the place; S2: stick the reinforcing tape at two glued positions; S3: make a waist-shaped hole at the two positions where the reinforcing tape is applied; S4: apply glue on the reinforcing tape and the board on one side of the waist-shaped hole; S5: From one side of the upper panel to the end of the non-woven fabric handle attached to the side of the upper panel, pass the waist-shaped hole through the end of the non-woven fabric handle, and stick the end of the non-woven fabric handle to the glued position of the reinforcing band and the board S6: Ultrasonic welding of the non-woven fabric handle and the reinforcing tape by an ultrasonic welding device to form a whole body; S7: then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com