Preparation method for molybdenum selenide two-dimensional layer titanium carbide composite material

A two-dimensional layered and composite material technology, applied in the direction of electrodes, electrical components, electrolysis process, etc., can solve the problems of low ion mobility, poor conductivity of molybdenum selenide, etc., achieve large specific surface area, easy to control, and convenient for industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

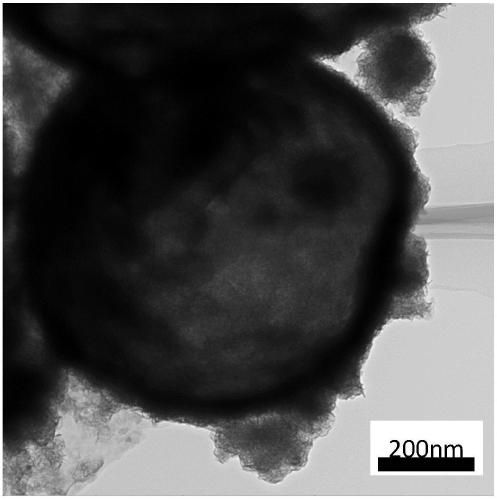

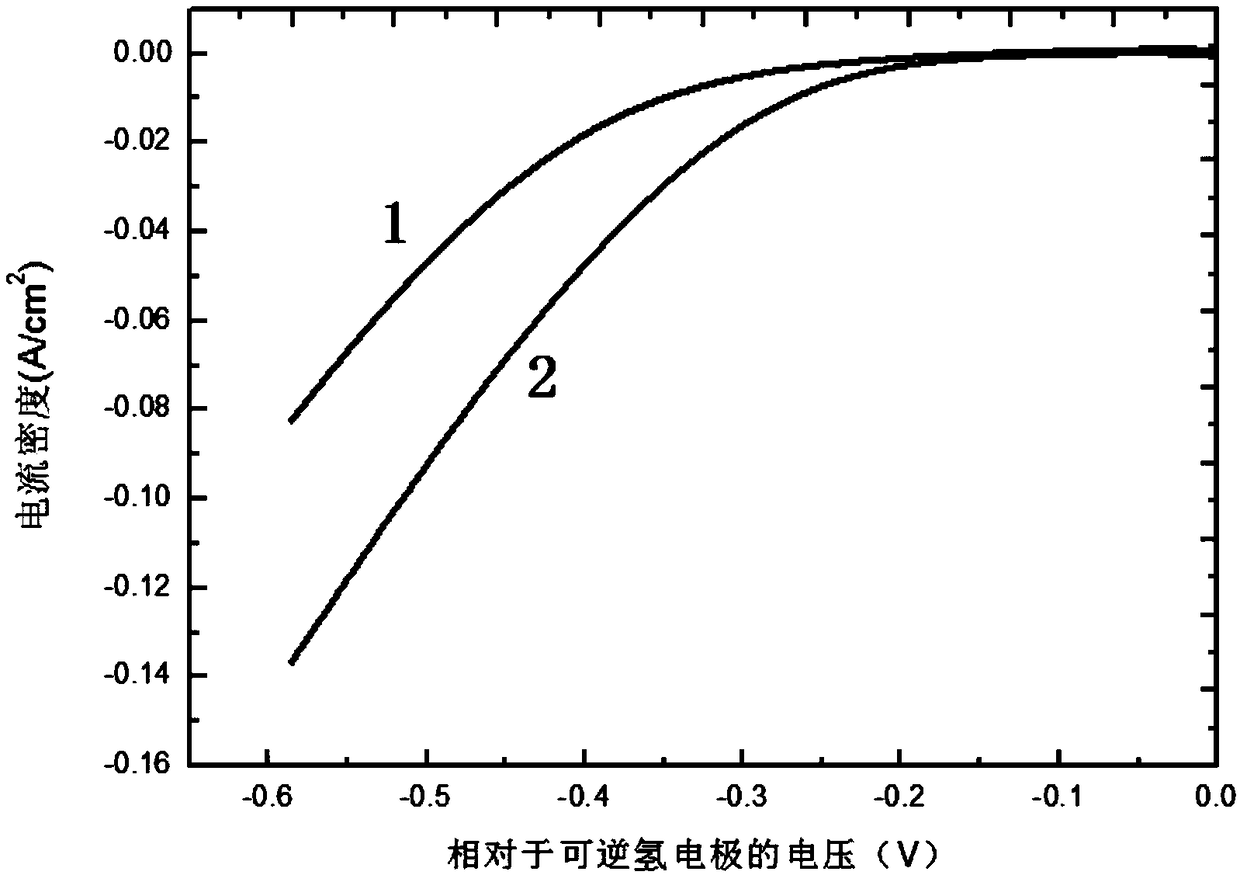

[0031] Specific implementation manner 1: The preparation method of the molybdenum selenide two-dimensional layered titanium carbide composite material of this embodiment is carried out according to the following steps:

[0032] 1. Mix Se powder and hydrazine hydrate with a mass percentage of 97% to 98% and stir for 12 to 24 hours to obtain a selenium-hydrazine hydrate dispersion;

[0033] The volume ratio of the mole of Se powder to the hydrazine hydrate with a mass percentage of 97% to 98% is (0.8 to 1.3) mmol: 5 mL;

[0034] Second, the MXene-Ti 3 C 2 The dispersion is mixed with cetyltrimethylammonium bromide, stirred for 0.5h~2h under the condition of 30℃~50℃, sodium molybdate is added and stirred for 0.2h~2h to obtain cetyltrimethylammonium bromide Base ammonium bromide solution;

[0035] MXene-Ti 3 C 2 The volume ratio of the dispersion liquid to the mass ratio of cetyltrimethylammonium bromide is (10~50) mL:1g; the MXene-Ti 3 C 2 The molar ratio of the volume of the dispersion ...

specific Embodiment approach 2

[0055] Specific embodiment two: this embodiment is different from specific embodiment one in that the volume ratio of the mole of Se powder to the hydrazine hydrate with a mass percentage of 97%-98% in step one is (0.8-1) mmol: 5mL. Others are the same as the first embodiment.

specific Embodiment approach 3

[0056] Specific embodiment three: this embodiment is different from one of specific embodiments one or two in: MXene-Ti described in step two 3 C 2 The mass ratio of the volume of the dispersion to the mass of cetyltrimethylammonium bromide is (10-40) mL: 1g; the MXene-Ti described in step two 3 C 2 The molar ratio of the volume of the dispersion to the sodium molybdate is (10-12) mL: 1 mmol. Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com