A kind of activated carbon electrode and preparation method thereof

A technology of activated carbon and electrodes, which is applied in the field of electrochemistry, can solve the problems of insignificant increase in conductivity, poor electronic conductivity, and large internal resistance of electrodes, and achieve the effects of reducing electronic resistance, improving conductivity, and reducing electrode resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

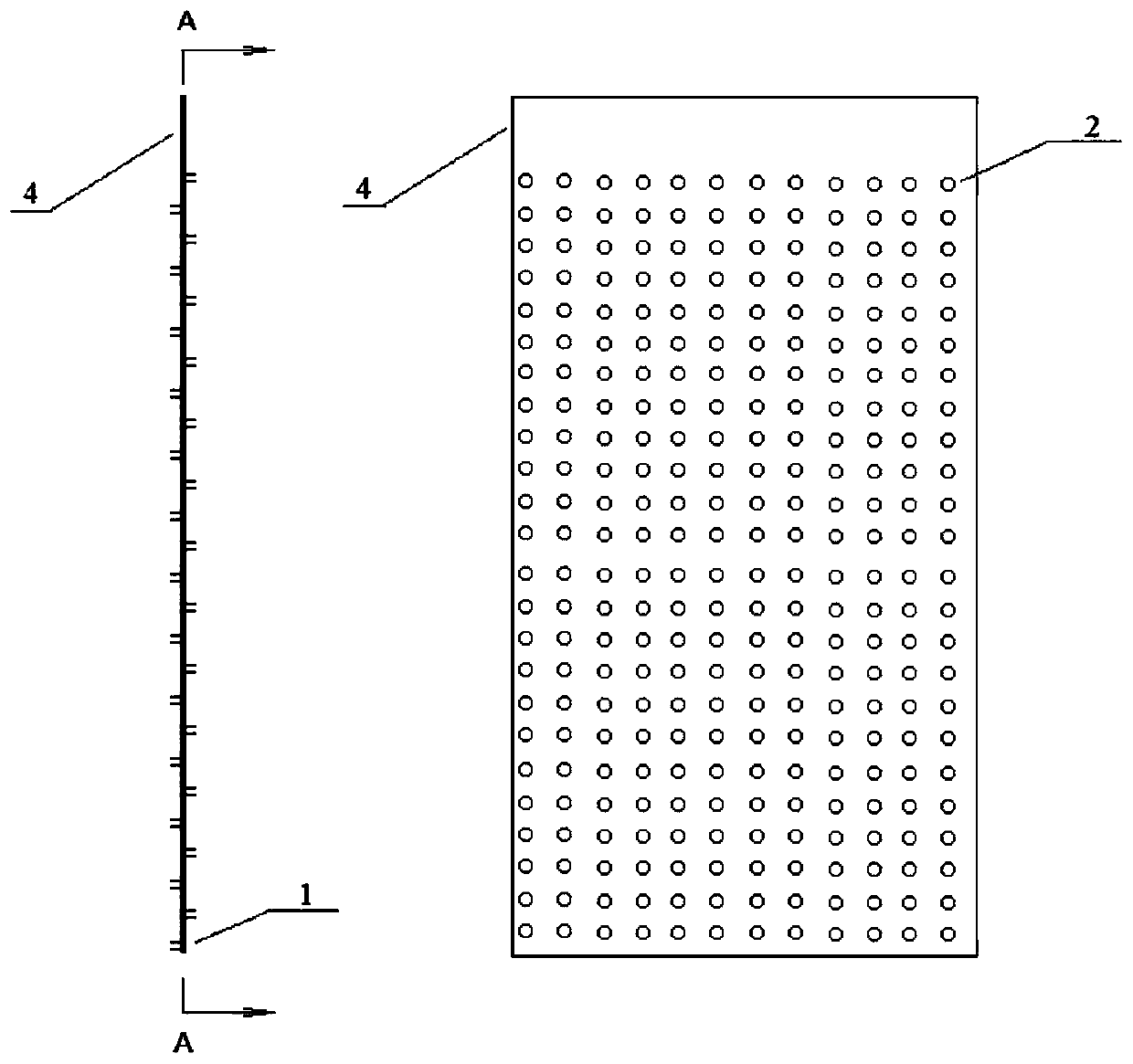

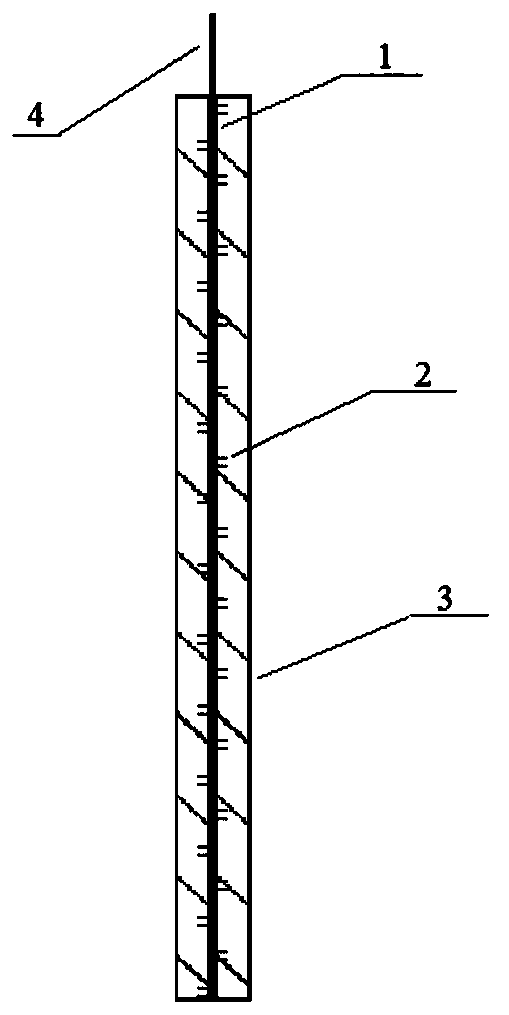

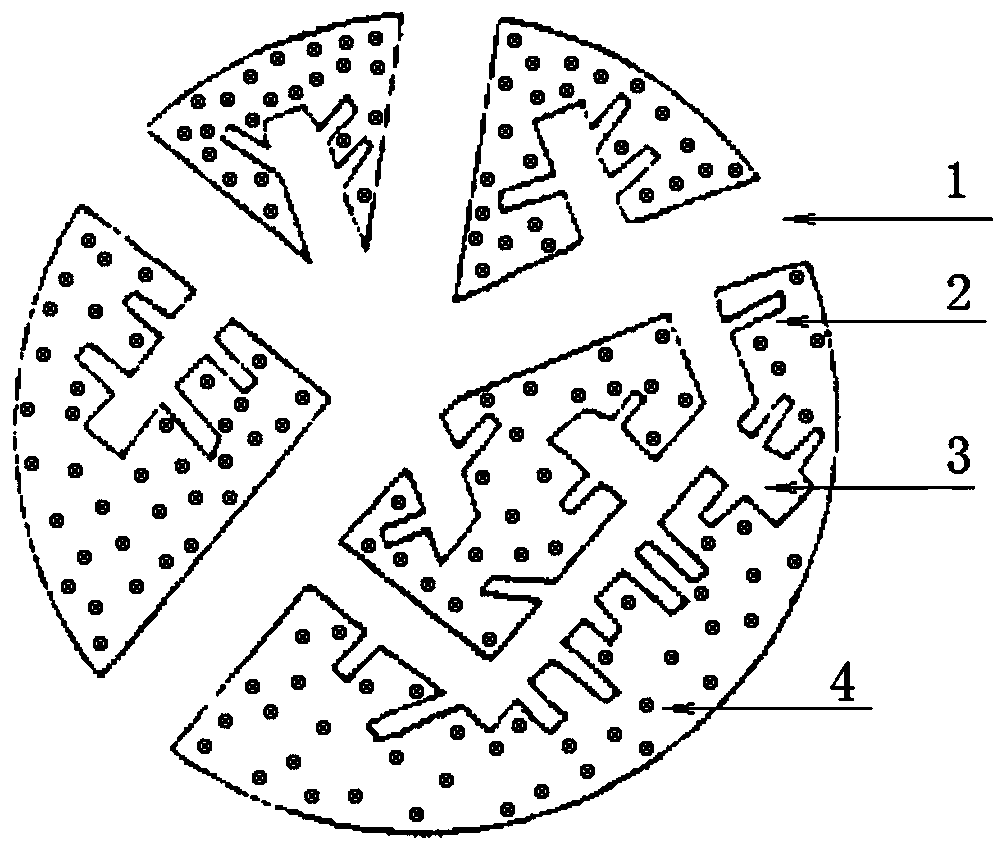

[0038] In the present invention, when the surface of the current collector includes thorn-like protrusions, the method for preparing the current collector preferably includes: stamping the base material with a die to obtain the current collector including thorn-like protrusions. In the present invention, the die is preferably inlaid with a steel needle, and the steel needle is preferably cylindrical; the end surface of the steel needle includes a protrusion, and the protrusion is preferably a triangular protrusion, a quadrangular protrusion, or a star-shaped protrusion. raised or rounded. In the present invention, the diameter of the cylindrical steel needle is preferably 0.2-0.6 mm, and the height of the protrusion on the end surface of the steel needle is preferably 100-200 μm. In the present invention, there is no special requirement for the stamping process, and the stamping process well known to those skilled in the art can be used.

[0039] In the present invention, bes...

Embodiment 1

[0152] Preparation of activated carbon:

[0153] ①Mix epoxy resin, tantalum ethoxide, p-toluenesulfonic acid and acetone at a weight ratio of 100:10:10:200 at 20°C and fully stir to dissolve to obtain a mixed solution; ②Heat the above solution to 70°C, and then Add water dropwise to the mixed solution and keep stirring until the organic metal salt is completely hydrolyzed to obtain a hydrolyzed complex. The time is about 2 hours, and the amount of water added is about 200mL; The curing time is about 10 hours to obtain the solidified material, and the particle size of the solidified material after pulverization is controlled at D50 of 50 μm; ④ After the solidified material is pulverized, it is heated and oxidized in a fluidized bed at 260 °C for 3 hours to obtain a composite oxidation product; ⑤The The composite oxidation product was pressed into a thin sheet with a thickness of 2 mm and a diameter of 5 mm under a pressure of 1 MPa; ⑥ Put the preform into a carbonization reacti...

Embodiment 2

[0157] Preparation of long-array carbon nanotubes, using 500 μm alumina pellets as inert particles to dry-load co-precipitation Fe / Mg / Al sheet catalyst fixed bed to prepare long-array carbon nanotubes:

[0158] ① Put 2g Fe(NO 3 )3.9H 2 O, 3.2g Mg(NO 3 ) 2.6 H2O and 2.35g Al(NO 3 ) 3.9 h 2 Dissolve O in 125ml of deionized water, add 22.5g of urea, reflux at 100°C for 12h for co-precipitation reaction, then stand at 95°C for 12h, cool, filter, wash with deionized water, and freeze-dry to obtain Fe / Mg / Al Layered double hydroxyl metal hydroxide sheet catalyst, wherein Fe is the active component. ②Put 500μm alumina pellets in a porcelain boat, then place the porcelain boat in a horizontal fixed-bed reactor, and raise the temperature of the reactor from room temperature to the pretreatment temperature of 800°C at a rate of 10°C / min under the protection of argon. °C, keep the temperature for 0.5h and then drop to room temperature under the protection of argon. The alumina pel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com