A bulb-shaped o-mx n /c nano reactor and its preparation method and application

A nano-reactor and reactor technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of uneven compounding of carbon and active materials, difficulty in controlling the microstructure of materials, and complicated preparation processes and other problems, to achieve the effects of alleviating structural changes and volume collapse, excellent high-rate performance and cycle stability, and improving intrinsic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A bulb-shaped O-MX of this embodiment n The preparation method of / C nanometer reactor, step is as follows:

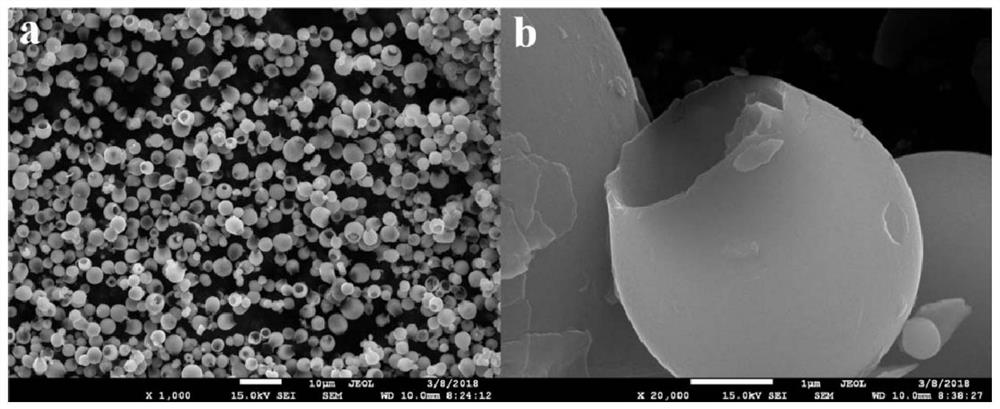

[0040] Dissolve 0.1 mmol sodium molybdate in 1 mL of aqueous solution to form S1 solution; dissolve 0.5 mmol dodecyltrimethylammonium bromide in 200 mL of glycerol to form S2 solution; add S1 solution dropwise to S2 solution A water-in-oil microemulsion was formed in the microemulsion; 0.1 mmol of the corresponding cysteine was added to the microemulsion; finally, MoS was prepared by hydrothermal reaction at 220 °C for 2 h 2 Precursor, its FESEM photo is as figure 1 As shown, the morphology of the precursor is a hollow bulb-like opening.

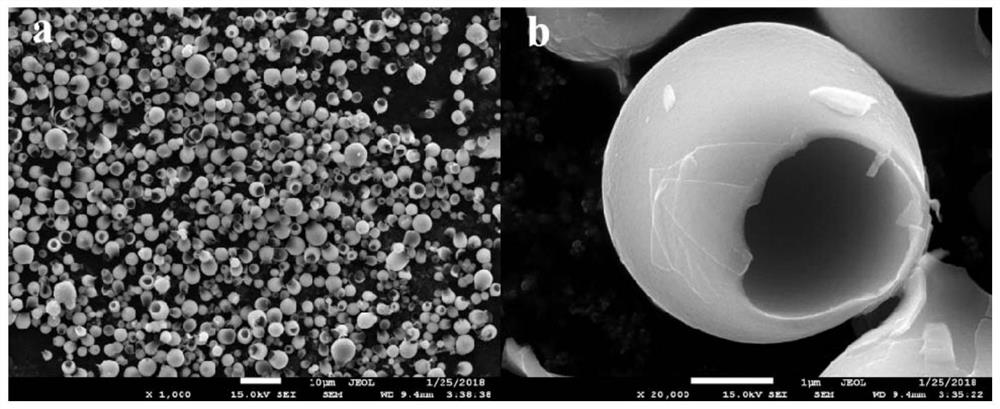

[0041] The precursor is placed in a tube furnace for heat treatment, the heating rate is 20 ℃ / min, the calcination time is 6 h, the calcination temperature is 700 ℃, the calcination atmosphere is argon, and the product is a bulb-shaped O-MoS 1.5 / C nanoreactor, its FESEM photo is as figure 2 Shown: O-MoS obtained after ...

Embodiment 2

[0043] A bulb-shaped O-MX of this embodiment n The preparation method of / C nanometer reactor, step is as follows:

[0044] Dissolve 5mmol sodium molybdate in 50 mL of aqueous solution to form S1 solution; dissolve 20mmol dodecyltrimethylammonium chloride in 200mL of glycerol to form S2 solution; add S1 solution dropwise to S2 solution to form Water-in-oil microemulsion; add 10 mmol of the corresponding cysteine to the microemulsion; finally, hydrothermal reaction at 160 °C for 48 h to prepare MoS 2 Precursor.

[0045] The precursor is placed in a tube furnace for heat treatment, the heating rate is 20 ℃ / min, the calcination time is 6 h, the calcination temperature is 700 ℃, the calcination atmosphere is argon, and the product is a bulb-shaped O-MoS 1.5 / C nanoreactor.

Embodiment 3

[0047] A bulb-shaped O-MX of this embodiment n The preparation method of / C nanometer reactor, step is as follows:

[0048] Dissolve 3 mmol ammonium molybdate in 30 mL of aqueous solution to form S1 solution; dissolve 10 mmol cetylpyridinium bromide in 100 mL of glycerol to form S2 solution; add S1 solution dropwise to S2 solution to form Water-in-oil microemulsion; add 5 mmol of the corresponding thiourea to the microemulsion; finally, hydrothermal reaction at 200 ℃ for 24 h to prepare MoS 2 Precursor.

[0049] The precursor is placed in a tube furnace for heat treatment, the heating rate is 20 ℃ / min, the calcination time is 6 h, the calcination temperature is 700 ℃, the calcination atmosphere is argon, and the product is a bulb-shaped O-MoS 1.5 / C nanoreactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com